Carbon composite sodion anode material and preparation method thereof

A cathode material, sodium ion technology, applied in battery electrodes, electrical components, non-aqueous electrolyte batteries, etc., can solve the problems of low conductivity of surface carbon layer coating, insufficient carbonization of organic carbon sources, and little effect of conductivity , to achieve the effect of improving charge transport capacity, inhibiting the production of impurity phase, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of carbon composite sodium ion cathode material is synthesized according to the following steps:

[0029] S0, drying ferrous sulfate hydrate in vacuum to obtain anhydrous ferrous sulfate, specifically, the drying temperature is 25°C-250°C, and the drying time is 1h-48h.

[0030] S1. Mix anhydrous ferrous sulfate, sodium sulfate and carbon-based materials to form a mixed material. Specifically, mix the above-mentioned dried anhydrous ferrous sulfate with sodium sulfate and carbon-based materials, wherein sodium sulfate and The molar ratio of ferrous sulfate water is 1:2 to 3:1. Specifically, the molar ratio of the sodium sulfate and the anhydrous ferrous sulfate can be 1:1, 1:2, 2:1, 3:1 or 3 : 5 mixed, the carbon-based material is carbon nanotube, carbon fiber, reduced graphene oxide or graphene etc., in the mixed material, the carbon-based material quality is 1% of the ferrous sulfate and sodium sulfate mixture -10%.

[0031] S12. Grinding and mi...

Embodiment 1

[0039] S0. Vacuum-dry ferrous sulfate heptahydrate in an oven at 200°C for 10 hours to obtain anhydrous ferrous sulfate.

[0040] S1. Weigh 0.77g sodium sulfate and 1.365g FeSO 4 and 0.1068g CNT were added to a 50mL zirconia ball mill jar for mixing.

[0041] S12. Add 45g of zirconia balls, set the ball-to-material ratio to 1:20, fill it with argon gas protection, and perform ball milling. The ball milling speed is 600r / min, the revolution speed is 1000r / min, and the ball milling time is 6h, and the positive electrode material is obtained. Precursor.

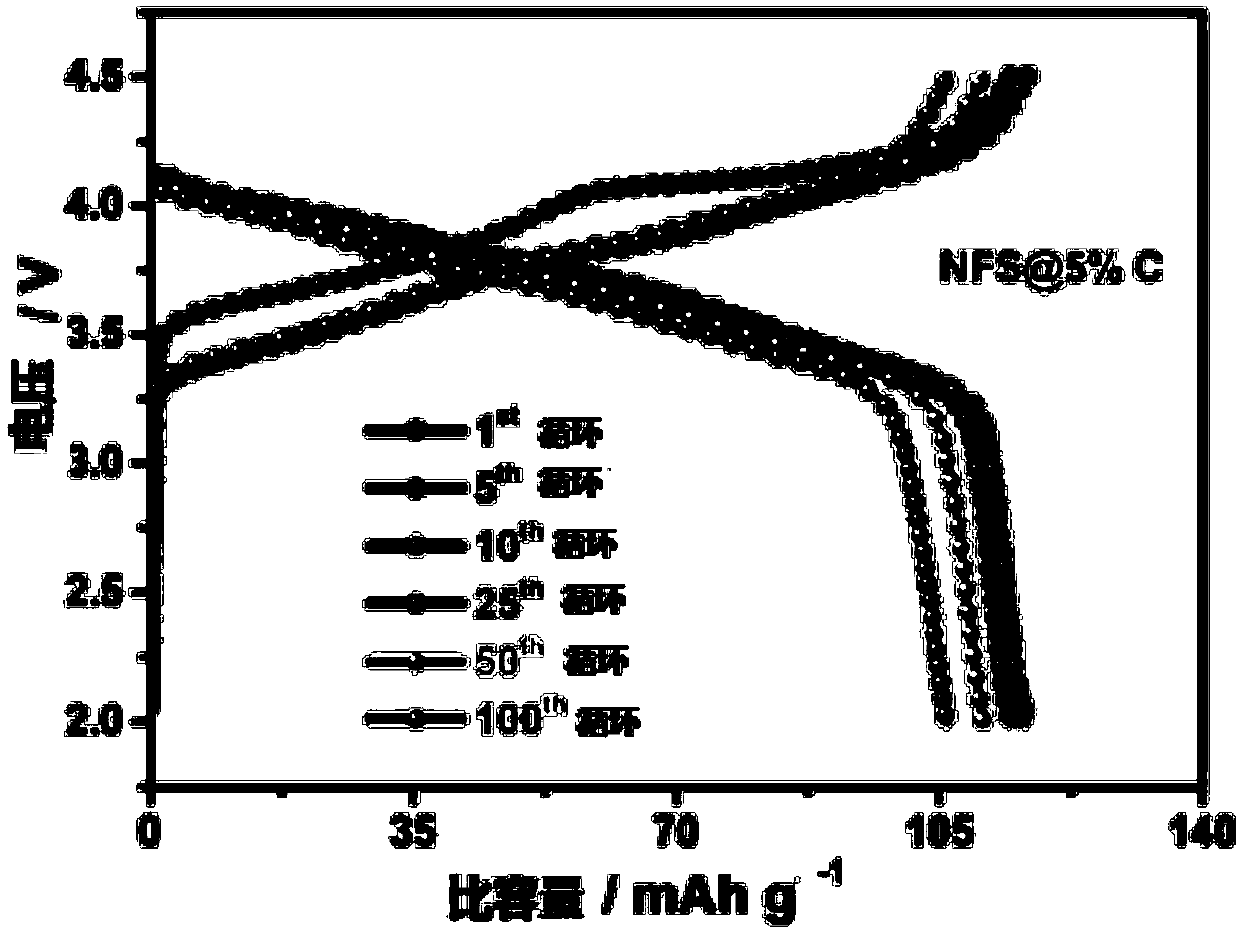

[0042] S2. Transfer the above-mentioned positive electrode material precursor to a tube furnace, perform heat treatment under an argon protective atmosphere, sinter at 350° C. for 5 hours, and grind the sintered product into powder to obtain a 5% carbon nanotube composite sodium ion positive electrode material, named Na 6 Fe 5 (SO 4 ) 8 / CNT-5%.

[0043] like figure 1 As shown, it can be seen that carbon nanotubes are cl...

Embodiment 2

[0049] S0. Vacuum-dry ferrous sulfate heptahydrate in an oven at 200°C for 10 hours to obtain anhydrous ferrous sulfate.

[0050] S1. Weigh 0.7102g of Na 2 SO 4 , 0.76g of FeSO 4 and 0.0735g CNF were added to a 50mL zirconia ball mill jar for mixing.

[0051] S12. Add 45g of zirconia balls, set the ball-to-material ratio to 1:20, fill with argon gas protection, and perform ball milling. The ball milling autopropagation rate is 600r / min, the revolution rate is 1000r / min, and the ball milling time is 6h to obtain the positive electrode material Precursor.

[0052] S2. Transfer the above positive electrode material precursor to a tube furnace, perform heat treatment under an argon protective atmosphere, sinter at 350° C. for 5 hours, and grind the sintered product into powder to obtain a 5% carbon nanotube composite sodium ion positive electrode material, named Na 2 Fe 1 (SO 4 ) 2 / CNF-5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com