Solar cell packaging board and its preparation process, solar cell and its packaging process

A technology for solar cells and preparation processes, applied in the field of solar cells, can solve the problems of poor light transmittance, poor water vapor barrier effect, and long process time of transparent packaging films, so as to simplify the packaging lamination process, reduce water vapor transmission rate, The effect of simple encapsulation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0087] In order to understand the above-mentioned purpose, features and advantages of the present invention more clearly, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be noted that, in the case of no conflict, the embodiments of the present application and the features in the embodiments can be combined with each other.

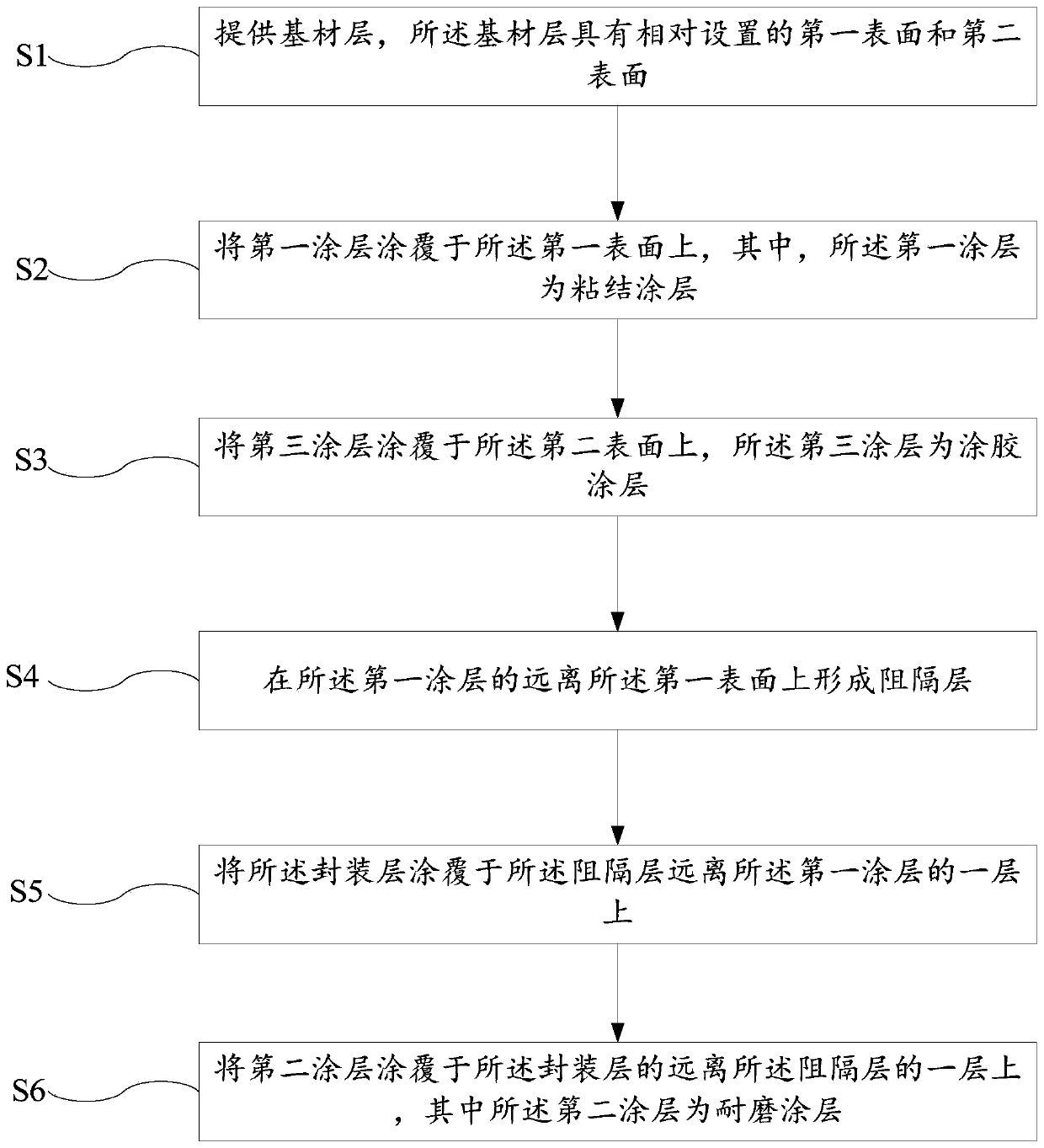

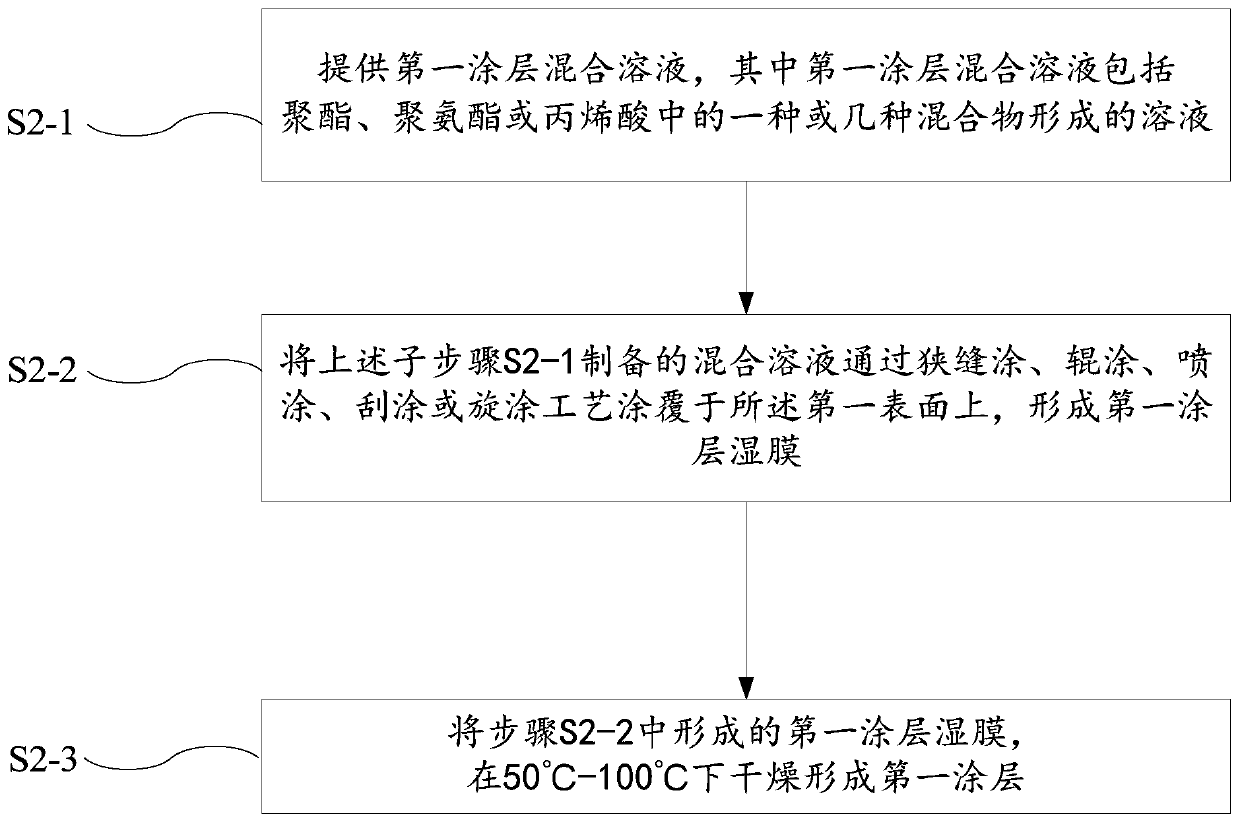

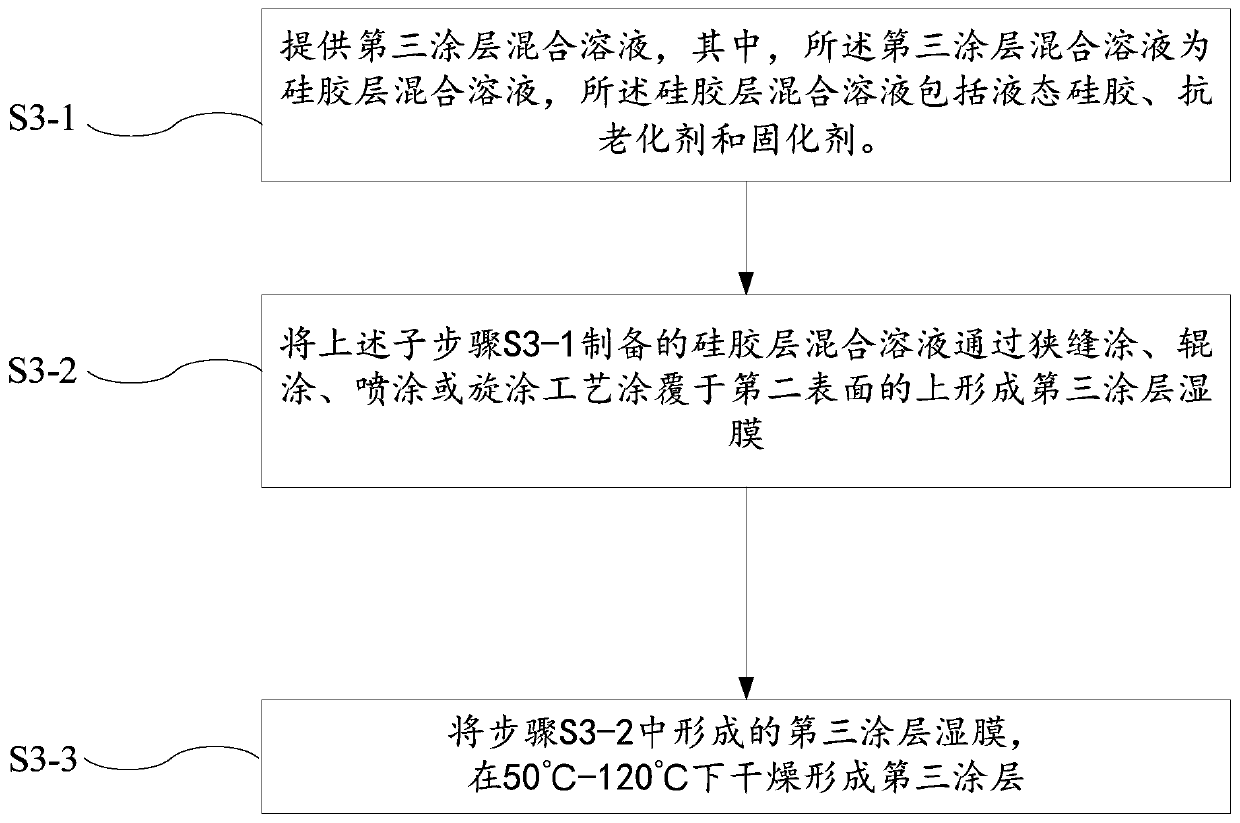

[0088] Such as figure 1 As shown, one embodiment of the present invention provides a preparation process of a solar cell packaging board, comprising the following steps:

[0089] S1. A substrate layer is provided, and the substrate layer has a first surface and a second surface opposite to each other.

[0090] The substrate layer can be a thermoplastic polyester film, using a high light transmittance and weather-resistant profile, specifically polyethylene terephthalate (PET), polyethylene naphthalate (PEN) or polyphthalic acid The film made of butanediol es...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com