Composite grid IGBT chip with three-dimensional channel

A compound gate and chip technology, applied in electrical components, circuits, semiconductor devices, etc., to achieve high current density, reduced output capacitance, and small parasitic capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0041] The composite gate IGBT chip of this embodiment includes a plurality of cells. In order to more clearly illustrate the composite gate IGBT chip of this embodiment, the following uses Figure 4 The schematic diagram of the structure of a single bar-shaped cell is shown as an example for detailed explanation.

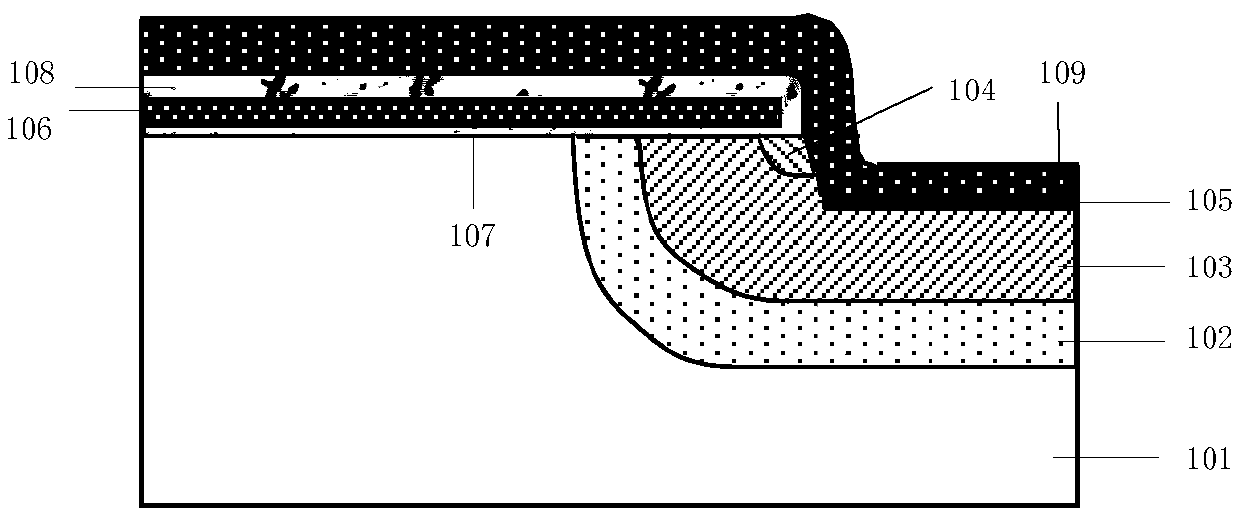

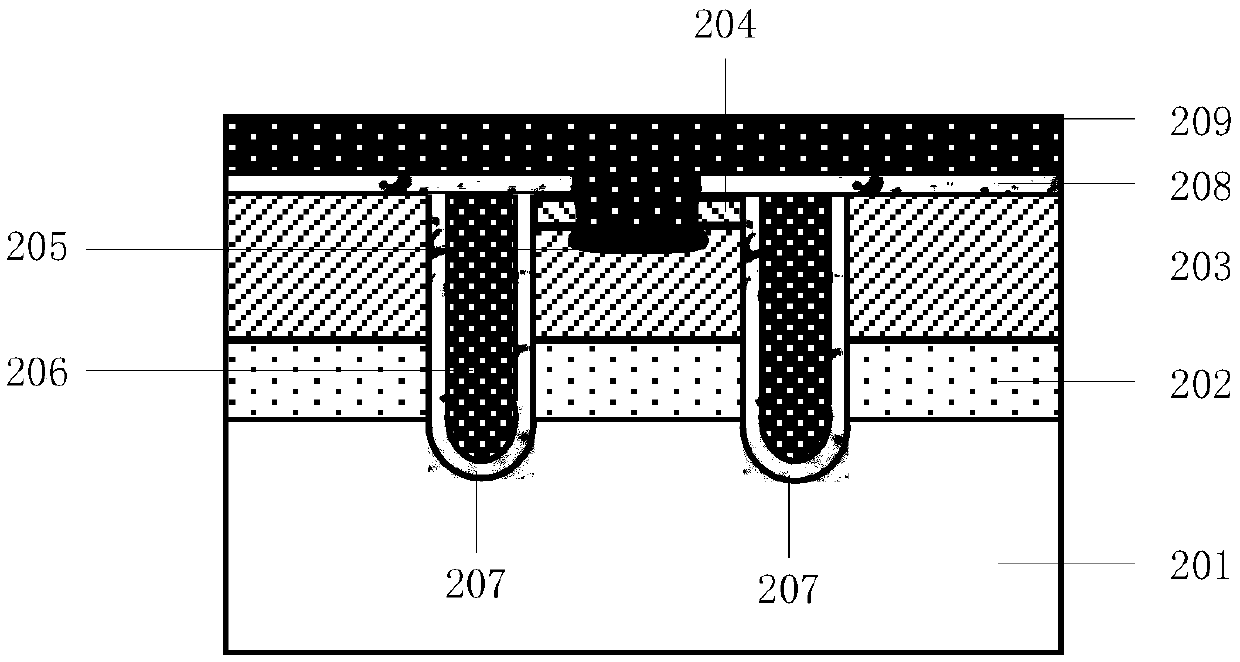

[0042] Figure 4 It is a schematic structural diagram of a composite gate IGBT chip with a three-dimensional channel in the first embodiment of the present invention. Such as Figure 4As shown, it includes a substrate 1 , cells disposed on the substrate 1 , and an N-type buffer layer 2 , a P-type layer 3 and an anode metal layer 4 disposed below the substrate 1 . Among them, the cell mainly includes: a trench polysilicon gate electrode 5, a first oxide layer 6, two P well regions 7, two doped regions (the doped regions include N++ doped regions 8 and P++ doped regions 9), Two second oxide layers 10 , two planar polysilicon gate electrodes 11 , two third oxide l...

no. 2 example

[0058] This embodiment is a further optimization of the first embodiment.

[0059] Figure 5 It is a schematic structural diagram of a composite gate IGBT chip with a three-dimensional channel in the second embodiment of the present invention. Such as Figure 5 shown in Figure 4 An N well region 15 is added to the shown cell. The N well region 15 is located below the P well region 7 and is in contact with the lower surface and the side of the P well region 7 , and the width of the N well region 15 is greater than that of the P well region 7 .

[0060] In this embodiment, an N well region is added around the P well region to further increase the conductance modulation effect of the IGBT chip in the drift region.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com