Preparation method and application of hybrid chemical sensor based on amphiphilic thermo-sensitive block copolymer

A chemical sensor, block copolymer technology, applied in scientific instruments, instruments, material analysis by optical means, etc., can solve problems such as inability to quantitatively detect, and achieve improved quantum yield, strong anti-interference ability, and good water solubility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

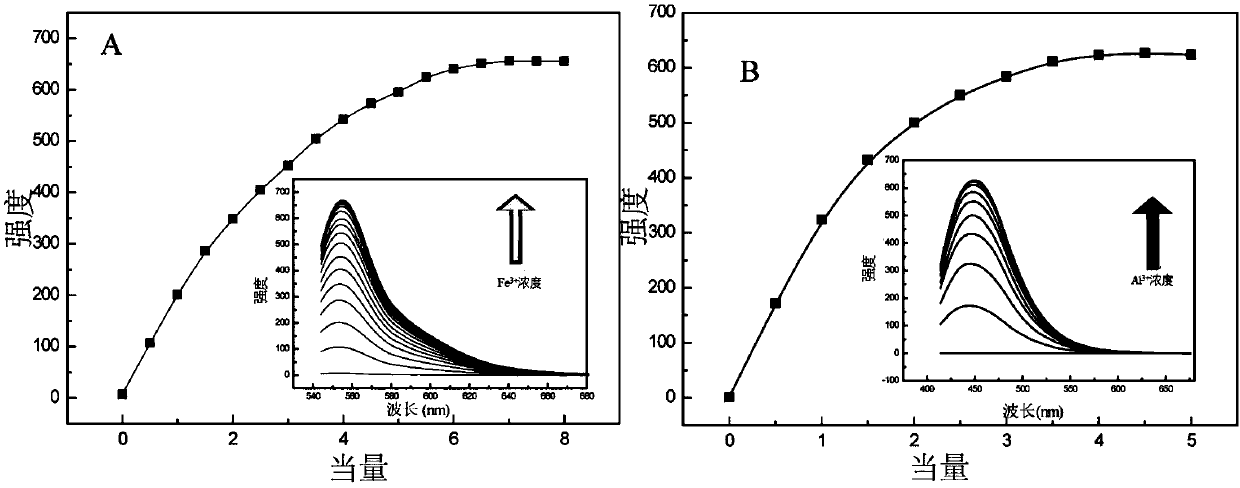

[0049] Example 1: Preparation of hybrid chemical sensors based on amphiphilic block copolymers

[0050] (1) Preparation of 2,4-dihydroxybenzaldehyde hydrazone BD:

[0051]

[0052] Benzohydrazide (1.36g, 0.01mol) was dissolved in ethanol (20.00mL), and a mixture of 2,4-dihydroxybenzaldehyde (1.38g, 0.01mol) and ethanol (20.00mL) was added dropwise while stirring. The temperature was raised to 60°C and stirred for 1 h, the solid precipitated out, and the crude product was obtained by cooling and filtration, and recrystallized three times in ethanol to obtain the scaly rose gold solid product BD (2.04 g, yield: 80.0%).

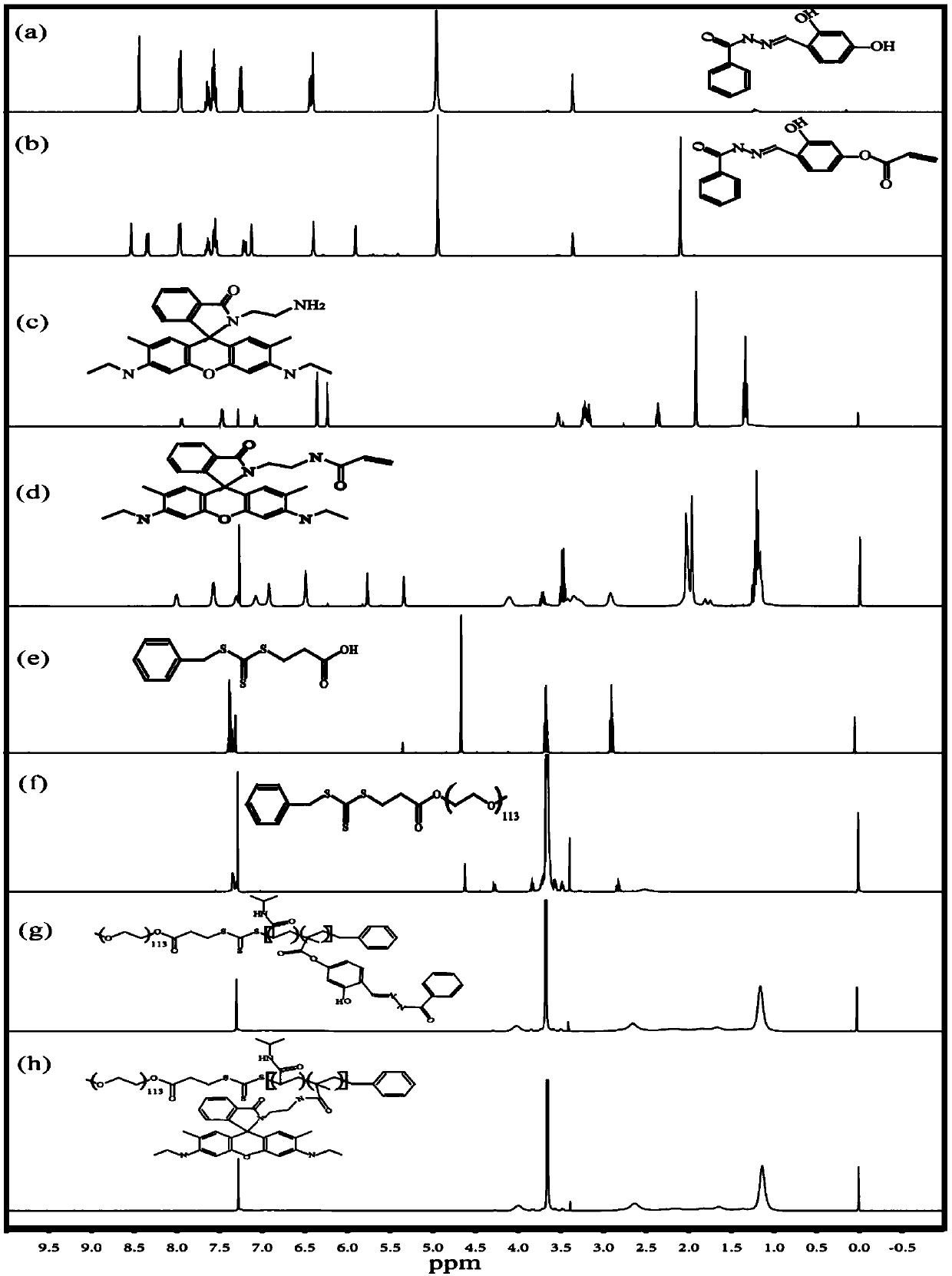

[0053] the resulting product 1 H NMR spectrum as figure 1 In a, the result is as follows:

[0054] 1 H NMR (CD 3 OD,δ,ppm):8.41(1H,ArCH=N-),7.90-7.95(2H,ArH),7.50-7.65(3H,ArH), 7.22(1H,ArH),6.35-6.45(2H,ArH) , proving that the material was synthesized successfully.

[0055] (2) Preparation of Schiff base derivative monomer (2,4-methacrylic benzal hydra...

Embodiment 2

[0091] Steps (1)-(6) are the same as in Example 1.

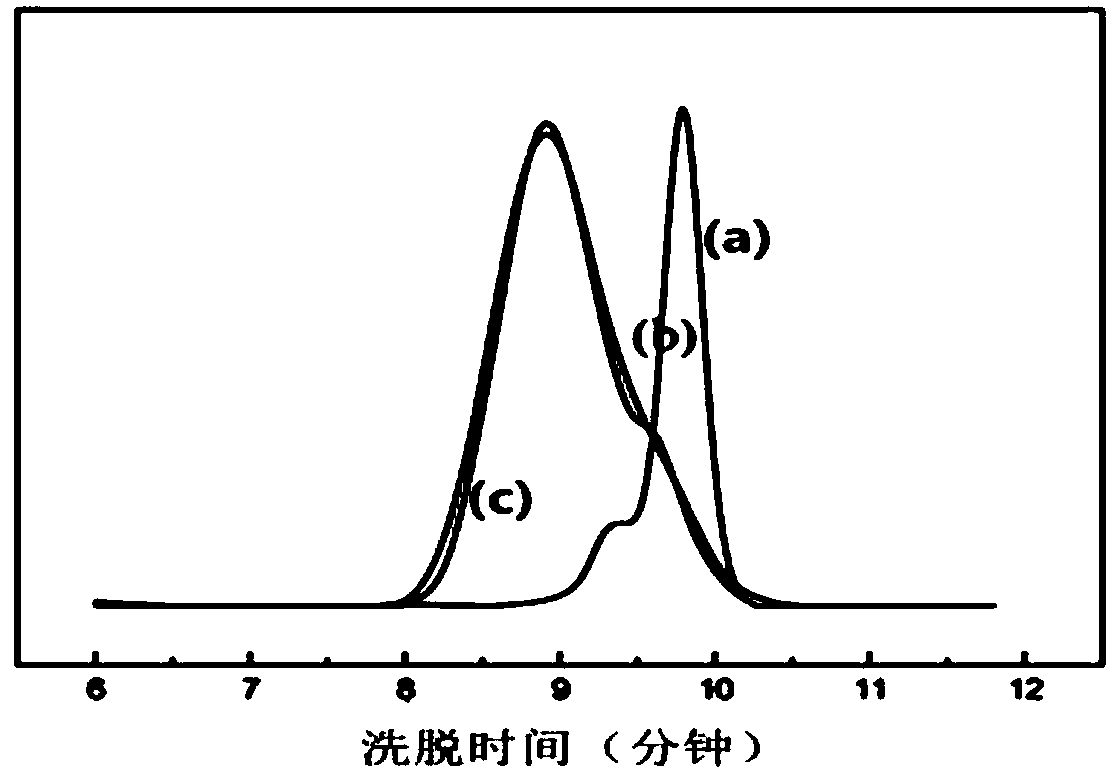

[0092] Step (7): In the one-mouth bottle, add magneton, NIPAM (0..6825g, 6.00mmol), BDMa (0.075g, 0.24mmol), polyethylene glycol monomethyl ether macromolecular chain transfer agent (0.315g, 0.06 mmol), AIBN (1.5 mg, 9 μmol) and 1,4-dioxane (1.05 g). The reaction raw materials were sealed under nitrogen atmosphere after three vacuum pumping-nitrogen filling cycles. After reacting in an oil bath at 60°C for 1 h, it was quenched in liquid nitrogen after the reaction. Diluted with 1,4-dioxane, and the mixture was precipitated and dissolved in excess ether, and the cycle was repeated three times.

[0093] Step (8): In the one-mouth bottle, add magneton, NIPAM (0..6825g, 6.00mmol), Rh6GEMa (0.075g, 0.24 mmol), polyethylene glycol monomethyl ether macromolecular chain transfer agent (0.315g, 0.06 mmol), AIBN (1.5 mg, 9 μmol) and 1,4-dioxane (1.05 g). The reaction raw materials were sealed under nitrogen atmosphere after three ...

Embodiment 3

[0096] Steps (1)-(6) are the same as in Example 1.

[0097] Step (7): In the one-mouth bottle, add magneton, NIPAM (1.1375g, 10.00mmol), BDMa (0.125g, 0.40mmol), polyethylene glycol monomethyl ether macromolecular chain transfer agent (0.525g, 0.10mmol ), AIBN (2.5 mg, 16 μmol) and 1,4-dioxane (1.75 g). The reaction raw materials were sealed under nitrogen atmosphere after three vacuum pumping-nitrogen filling cycles. After reacting in an oil bath at 80° C. for 2 h, it was quenched in liquid nitrogen after the reaction. Diluted with 1,4-dioxane, and the mixture was precipitated and dissolved in excess ether, and the cycle was repeated three times.

[0098] Step (8): In the one-mouth bottle, add magneton, NIPAM (1.1375g, 10.00mmol), Rh6GEMa (0.125g, 0.40 mmol), polyethylene glycol monomethyl ether macromolecular chain transfer agent (0.525g, 0.10mmol ), AIBN (2.5 mg, 16 μmol) and 1,4-dioxane (1.75 g). The reaction raw materials were sealed under nitrogen atmosphere after th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| number average molecular weight | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com