Bifunctional organic porous material and preparation method thereof

A dual-functional, organic framework technology, applied in the cross field, to achieve the effect of good selectivity, simple separation, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

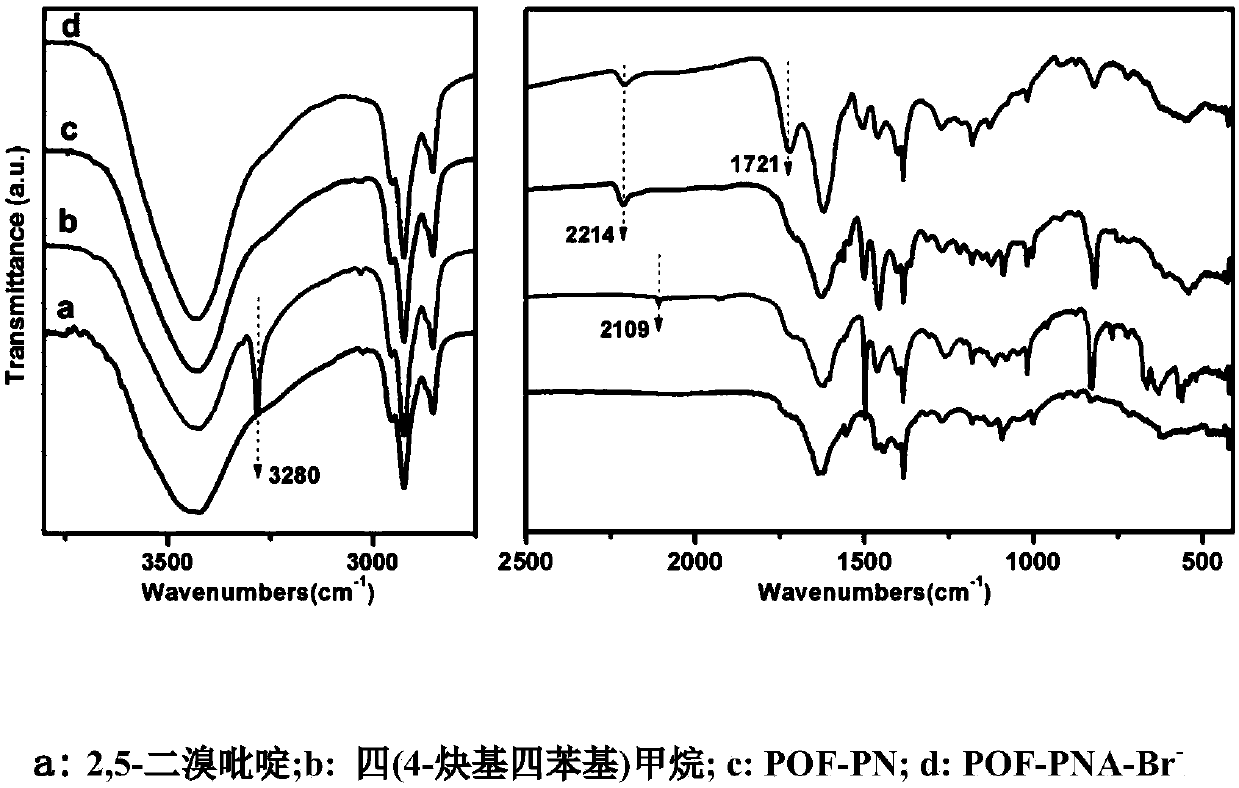

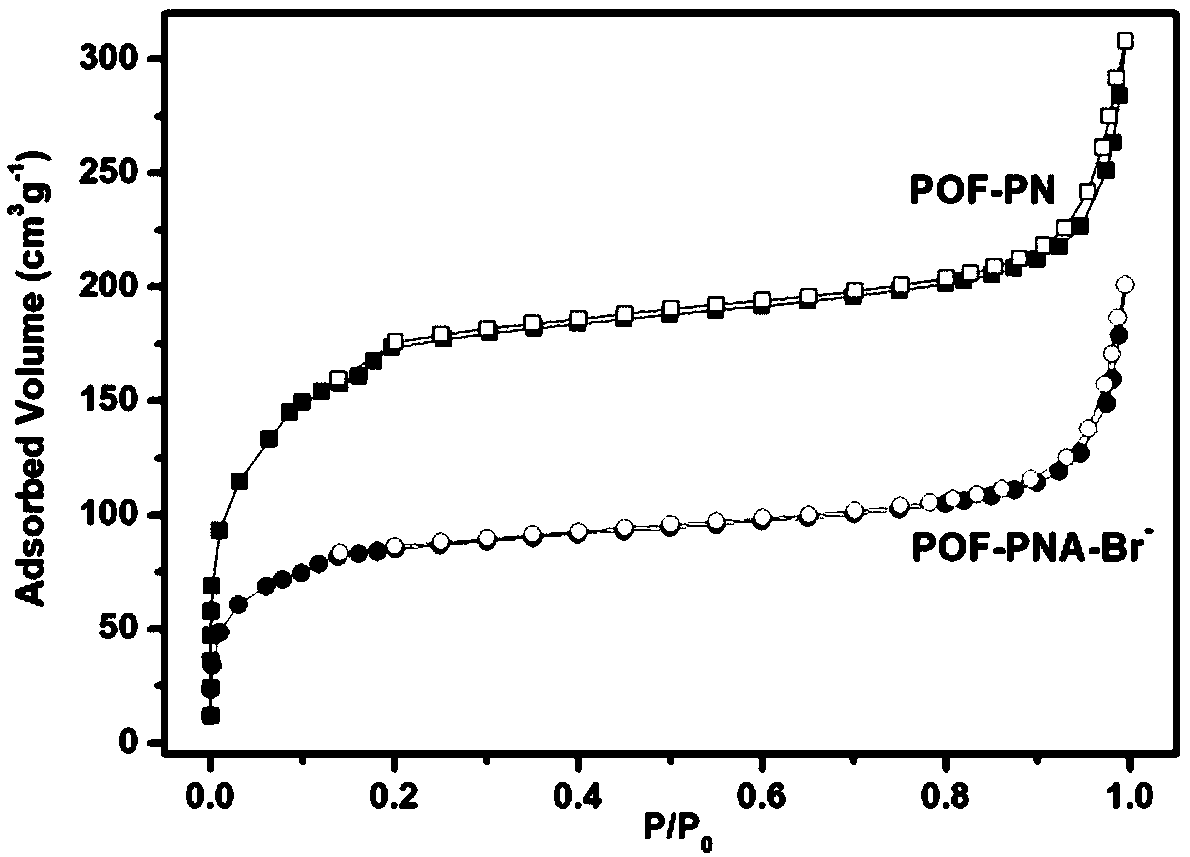

[0032] Step 1: Dissolve 0.5mmol tetrakis(4-alkynyltetraphenyl)methane, 1mmol 2,5-dibromopyridine, 0.0075mmol tetrakis(triphenylphosphine)palladium, and 0.0075mmol cuprous iodide in 4mL DMF and 2mL tris In the mixed solvent of ethylamine, the reaction system was subjected to freezing, evacuation and nitrogen filling three times, and then heated to 60° C. for 4 days to obtain a mixed solution.

[0033] Step 2: Filter the mixed solution obtained in Step 1, and wash the solid product 3 times with DMF, water, methanol and tetrahydrofuran solution respectively to remove soluble organic matter and catalyst, and dry it in vacuum at 80°C under the condition of vacuum degree of 133Pa After 15 hours, a porous organic framework material POF-PN containing pyridine sites was obtained.

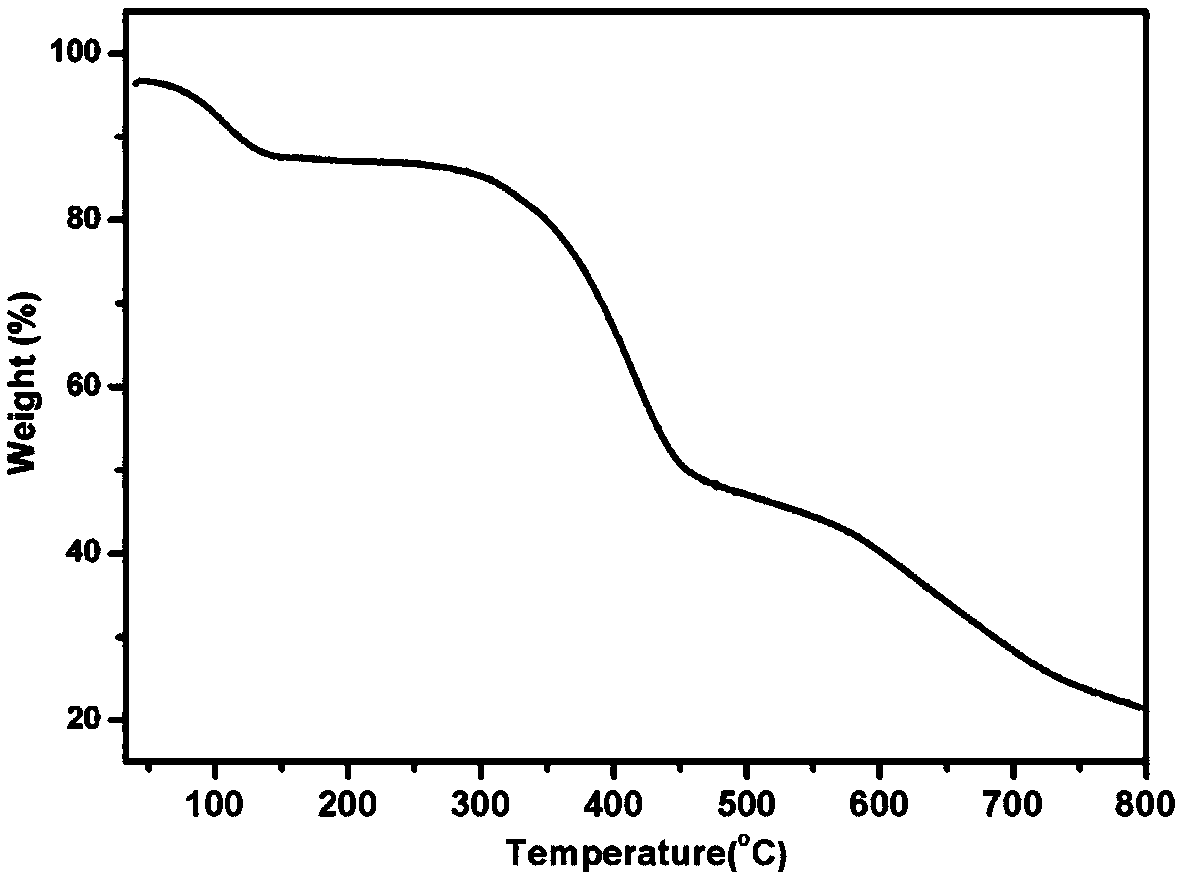

[0034] Step 3: At room temperature, disperse 1 mmol of the POF-PN in 25 mL of toluene solution, add 1.5 mmol of bromoacetic acid under nitrogen protection and stirring conditions, heat up to 50 ° C and react...

Embodiment 2

[0050] Step 1: Dissolve 0.5mmol tetrakis(4-alkynyltetraphenyl)methane, 1mmol 2,5-dibromopyridine, 0.01mmol tetrakis(triphenylphosphine)palladium, and 0.01mmol cuprous iodide in 5mL DMF and 2mL tris In the mixed solvent of ethylamine, the reaction system was subjected to freezing, evacuation and nitrogen filling three times, and then heated to 70° C. for 4 days to obtain a mixed solution.

[0051] Step 2: Filter the mixed solution obtained in Step 1, and wash the solid product 3 times with DMF, water, methanol and tetrahydrofuran solution to remove soluble organic matter and catalyst, and dry it in vacuum at 90°C under a vacuum degree of 133Pa After 12 hours, a porous organic framework material POF-PN containing pyridine sites was obtained.

[0052] Step 3: At room temperature, disperse 1 mmol of the POF-PN in 25 mL of toluene solution, add 2 mmol of bromoacetic acid under nitrogen protection and stirring conditions, heat up to 50 ° C and react for 2 days; cool to room temperat...

Embodiment 3

[0059] Step 1: Dissolve 0.5mmol tetrakis(4-alkynyltetraphenyl)methane, 1.5mmol 2,5-dibromopyridine, 0.015mmol tetrakis(triphenylphosphine)palladium, and 0.015mmol cuprous iodide in 6mL DMF and 3mL In a mixed solvent of triethylamine, the reaction system was subjected to freezing, evacuation, and nitrogen filling three times, and then heated to 80° C. for 3 days to obtain a mixed solution.

[0060] Step 2: Filter the mixed solution obtained in Step 1, and wash the solid product 5 times with DMF, water, methanol and tetrahydrofuran solution respectively to remove soluble organic matter and catalyst, and dry it in vacuum at 100°C under a vacuum degree of 133Pa After 12 hours, a porous organic framework material POF-PN containing pyridine sites was obtained.

[0061] Step 3: At room temperature, disperse 1 mmol of the POF-PN in 30 mL of toluene solution, add 2 mmol of bromoacetic acid under nitrogen protection and stirring conditions, heat up to 70 ° C and react for 2 days; cool t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com