Sulfuric-acid-corrosion-resistant low-alloy steel, steel pipe, steel plate and manufacturing methods of steel pipe and steel plate

A low-alloy steel and manufacturing method technology, applied in the field of low-alloy steel, steel products and its manufacturing, can solve the problems of low wear resistance, abrasive wear of materials, and unknown corrosion resistance, so as to improve the cost performance of materials, Good mechanical properties, the effect of improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-12

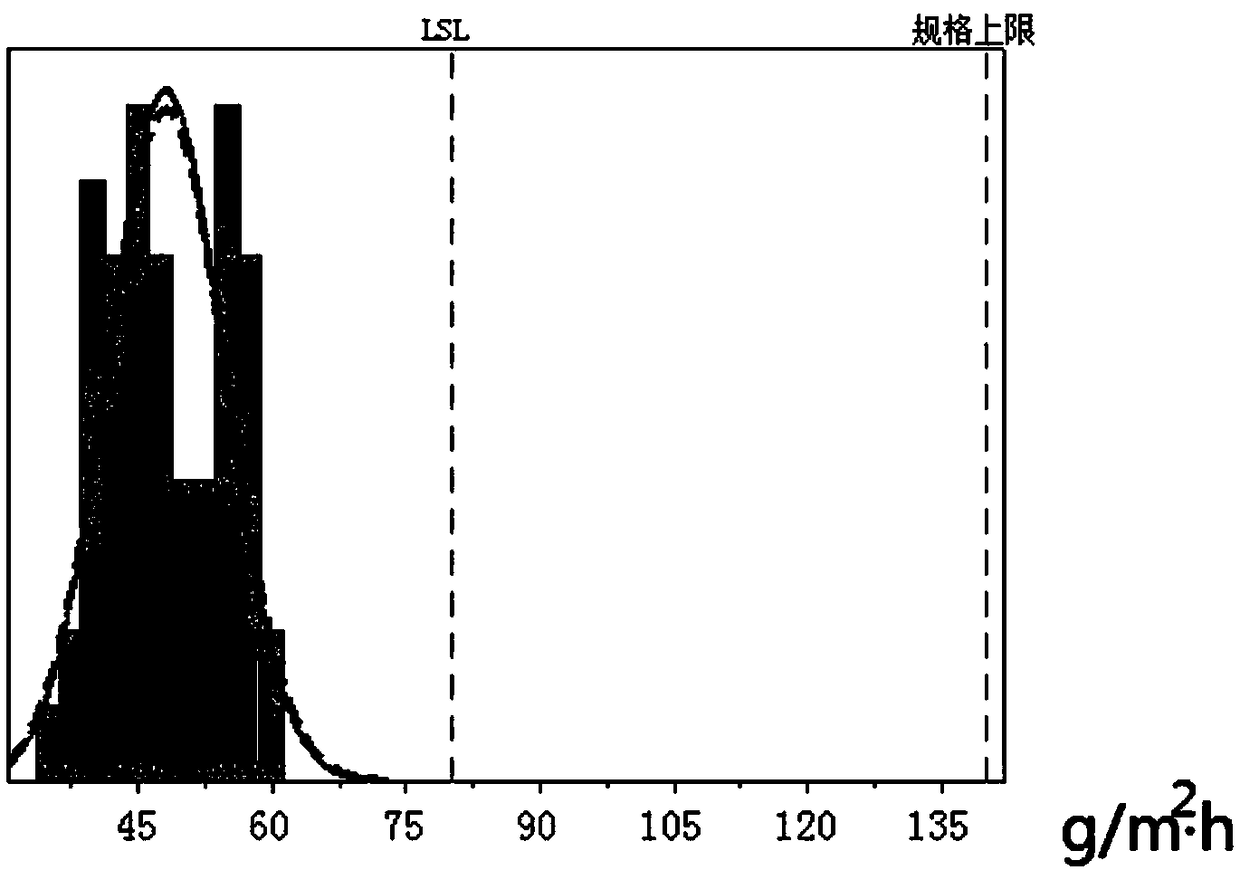

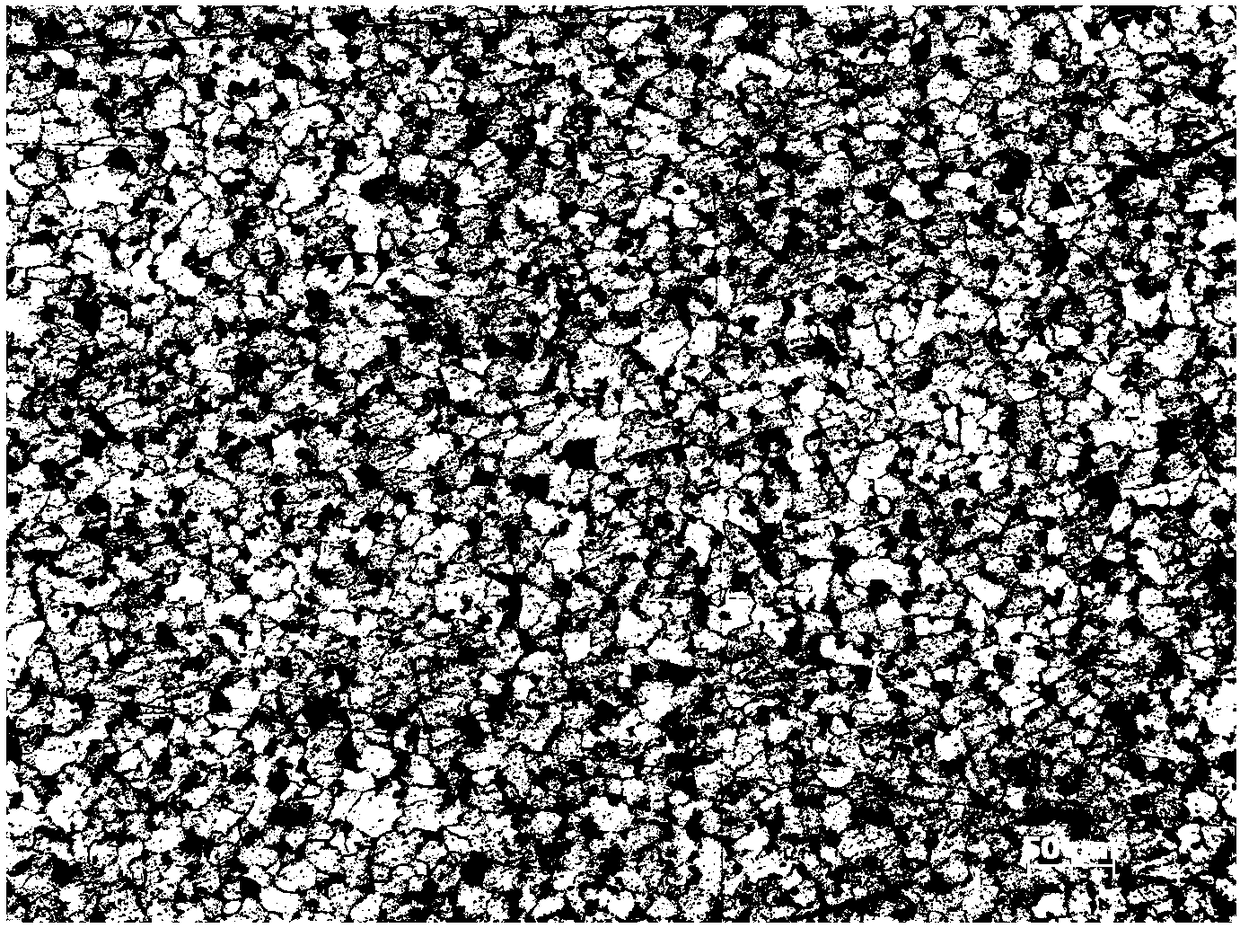

[0065] The sulfuric acid corrosion-resistant low-alloy steels of Examples 1-12 are smelted using the mass percentages of the chemical elements listed in Table 1, wherein the sulfuric acid-resistant low-alloy steels of Examples 1-6 are made into steel plates , The sulfuric acid corrosion-resistant low-alloy steels of Examples 7-12 were made into steel pipes.

[0066] Table 1. (wt%, the balance is Fe and other unavoidable impurity elements except P)

[0067]

[0068]

[0069] The sulfuric acid corrosion-resistant low-alloy steel of embodiment 1-3 is made into the manufacturing method of steel plate, comprises steps:

[0070] (1) Smelting and casting into slabs;

[0071] (2) Heating: heating temperature 1200-1350 ℃, holding time ≥ 60min;

[0072] (3) Hot rolling: finish rolling temperature ≥ 840°C, not normalizing after hot rolling.

[0073] (4) The quenching temperature is 820-930°C, the holding time is ≥5min, and then cooled, and the cooling rate is ≥5°C / s

[0074] Ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com