Preparation method of antimony/nitrogen doped graphene compound, and obtained material and application thereof

A nitrogen-doped graphene and composite technology, applied in electrical components, electrochemical generators, battery electrodes, etc., can solve the problem of poor cycle stability, loss of electrical contact between active materials and conductive additives, and reduced first-cycle Coulomb efficiency. and other problems, to achieve the effect of simple process, excellent electrochemical performance, and green raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Preparation of Sb / N-rGO composite

[0028] With 10mL graphene oxide dispersion (10mg mL) prepared by Hummers method -1 ), 300mg of purchased commercial antimony powder and 50mg of 1-ethyl-3-methylimidazolium dicyanamide were added into the ball mill jar, and ball milled at 800rpm for 24h. Add 10 mL of water to the ball-milled dispersion for dilution, take out the diluted mixture and ultrasonicate it in a digitally controlled ultrasonic cleaner for 5 minutes to form a uniform dispersion. The resulting solution was quickly frozen with liquid nitrogen and lyophilized for 2 days, and the resulting powder was placed in a single-temperature zone tube furnace under Ar / H 2 atmosphere (wherein H 2 Volume percentage is 5%), at 5°C min -1The speed was heated to 600 °C and kept at this temperature for 2 h to obtain the Sb / N-rGO composite.

[0029] (2) Characterization of antimony / nitrogen doped graphene composites

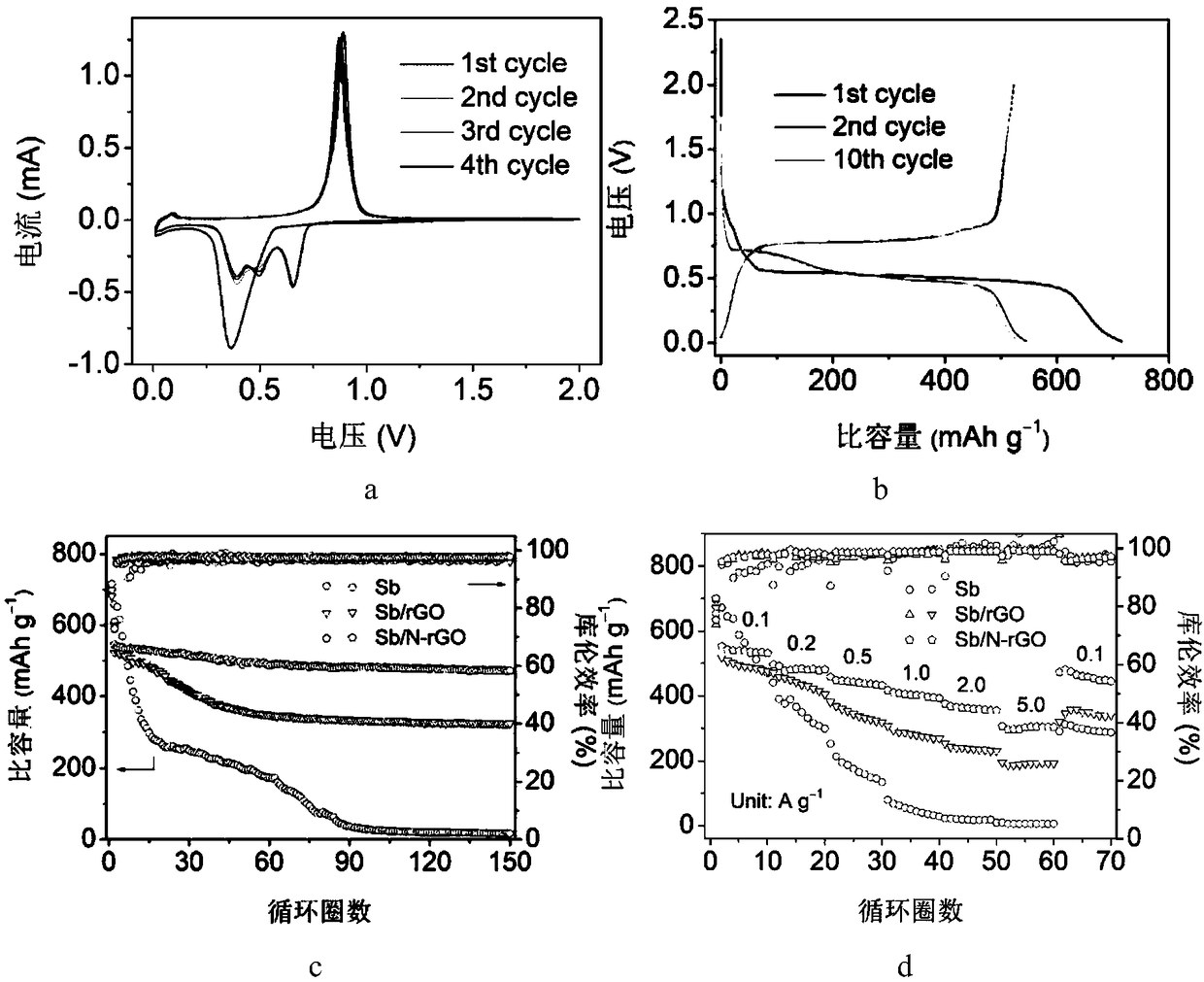

[0030] The size, morphology and microstructure of the obt...

Embodiment 2

[0047] With 10mL graphene oxide dispersion (10mg mL) prepared by Hummers method -1 ), 250 mg of purchased commercial antimony powder and 50 mg of 1-ethyl-3-methylimidazolium dicyanamide were added into a ball mill jar, and ball milled at 800 rpm for 24 hours. Add 10 mL of water to the ball-milled dispersion for dilution, take out the diluted mixture and ultrasonicate it in a digitally controlled ultrasonic cleaner for 5 minutes to form a uniform dispersion. The resulting solution was quickly frozen with liquid nitrogen and lyophilized for 2 days, and the resulting powder was placed in a single-temperature zone tube furnace under Ar / H 2 atmosphere (wherein H 2 5% by volume), at 4°C min -1 The speed was heated to 600 °C and kept at this temperature for 2 h to obtain the Sb / N-rGO-2 composite.

[0048] The structural characterization and electrochemical performance test of the prepared Sb / N-rGO-2 composite were carried out in the same manner as in Example 1, and the results wer...

Embodiment 3

[0050] With 10mL graphene oxide dispersion (10mg mL) prepared by Hummers method -1 ), 350mg of purchased commercial antimony powder and 50mg of 1-ethyl-3-methylimidazolium dicyanamide were added into the ball mill jar, and ball milled at 800rpm for 24h. Add 10 mL of water to the ball-milled dispersion for dilution, take out the diluted mixture and ultrasonicate it in a digitally controlled ultrasonic cleaner for 5 minutes to form a uniform dispersion. The resulting solution was quickly frozen with liquid nitrogen and lyophilized for 2 days, and the resulting powder was placed in a single-temperature zone tube furnace under Ar / H 2 atmosphere (wherein H 2 10% by volume), at 5°C min -1 The speed was heated to 600 °C and kept at this temperature for 3 h to obtain the Sb / N-rGO-3 composite.

[0051] According to the same method as in Example 1, the structural characterization and electrochemical performance test of the prepared Sb / N-rGO composite were carried out, and the results w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com