Modified cross-section fiber and moisture-absorbing and quick-drying fabric prepared from modified cross-section fiber

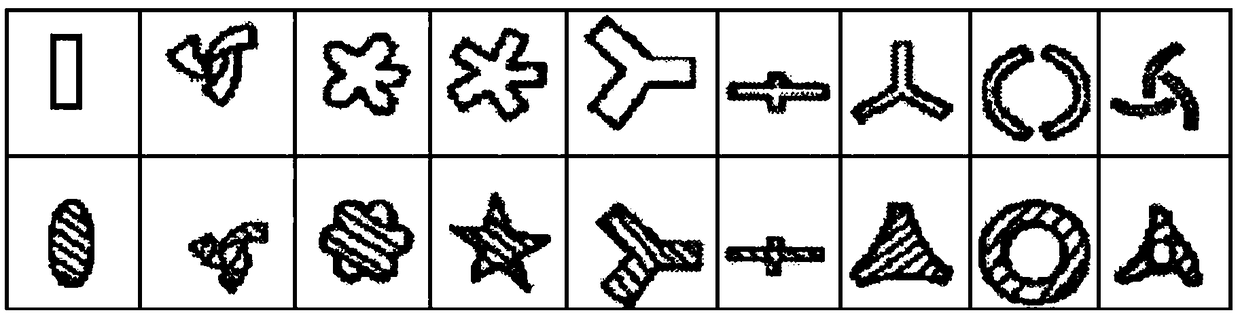

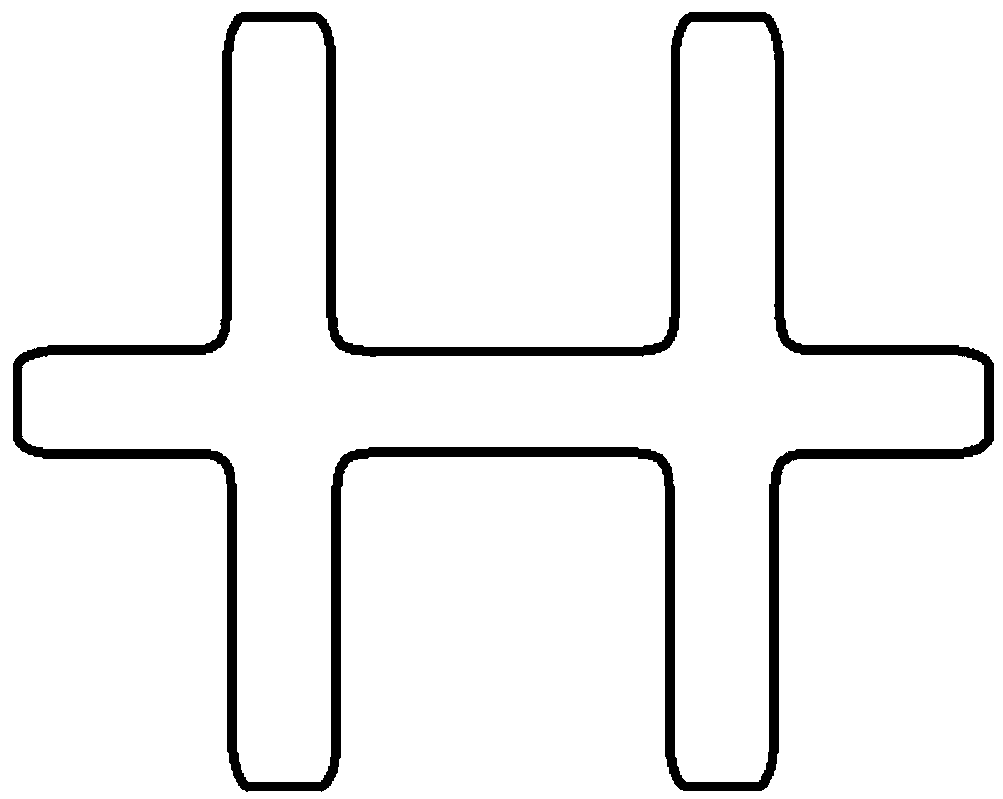

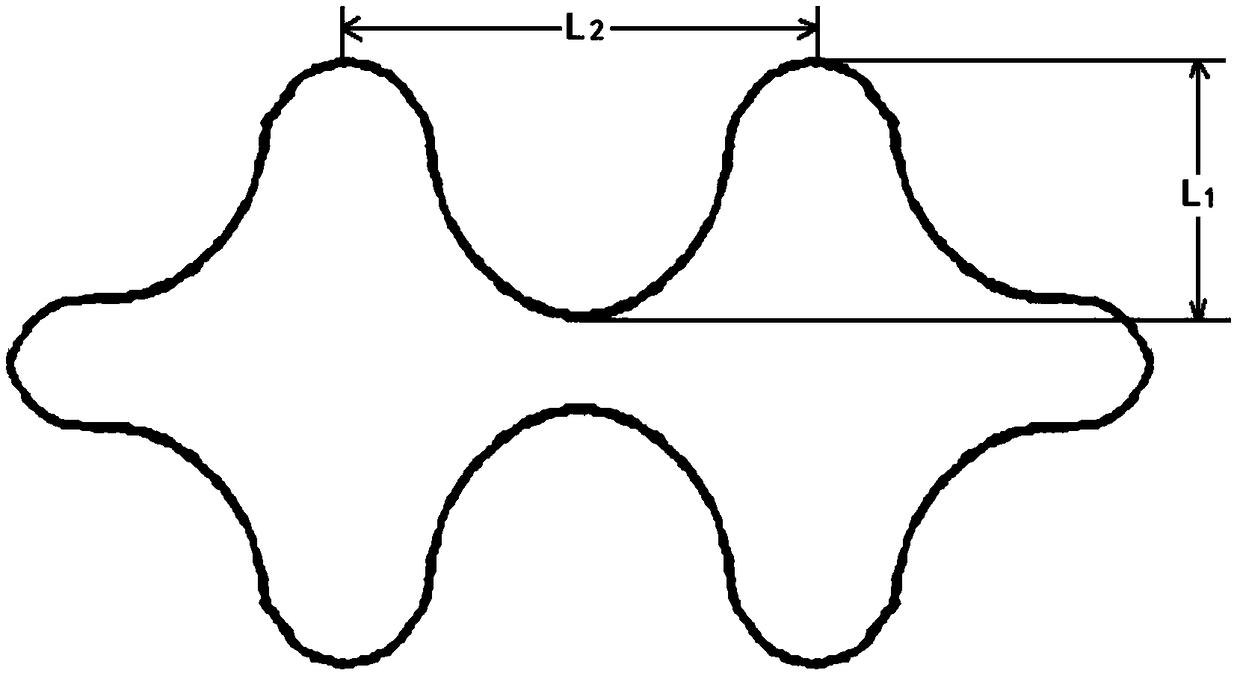

A special-shaped cross-section and fiber technology, applied in the field of textile fibers, can solve problems such as poor antibacterial properties and moisture residue, and achieve good moisture absorption and good wearing comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The preparation method of the special-shaped section fiber of the present embodiment is as follows:

[0031] 1. Preparation of Spinning Melt

[0032] 1.1 Transesterification reaction

[0033] Add dimethyl terephthalate (DMT), ethylene glycol (EG) and zinc acetate into the transesterification tank after metering (the molar ratio of EG to DMT is 2.3, and the addition of zinc acetate is 0.05wt% of DMT ), the temperature is raised to 200°C, and the methanol generated by the transesterification reaction is distilled off through the distillation tower on the top of the transesterification tank. When the distilled amount of methanol reaches 90% of the theoretical amount (theoretically, 1Kg of DMT generates about 0.417L of methanol) the ester is terminated. reaction.

[0034] 1.2 Polycondensation reaction

[0035] Add the reaction product in the polycondensation still, and add the pre-configured diethylene glycol isophthalate-5-sodium sulfonate (the addition is 0.50mol% of D...

Embodiment 2

[0039] The preparation method of the special-shaped section fiber of the present embodiment is as follows:

[0040] 1. Preparation of Spinning Melt

[0041] 1.1 Transesterification reaction

[0042] Add dimethyl terephthalate (DMT), ethylene glycol (EG) and zinc acetate into the transesterification tank after metering (the molar ratio of EG to DMT is 2.5, and the addition of zinc acetate is 0.05wt% of DMT ), the temperature is raised to 200° C., and the methanol generated by the transesterification reaction is distilled out through the distillation tower on the top of the transesterification tank, and the esterification reaction is terminated when the distilled amount of methanol reaches 90% of the theoretical generation amount.

[0043] 1.2 Polycondensation reaction

[0044] Add the reaction product in the polycondensation tank, and add pre-configured dimethyl isophthalate-5-sodium sulfonate (addition is 0.72mol% of DMT), N-hydroxysuccinimide (addition is DMT 0.50mol% of DMT...

Embodiment 3

[0048] The preparation method of the special-shaped section fiber of the present embodiment is as follows:

[0049] 1. Preparation of Spinning Melt

[0050] 1.1 Transesterification reaction

[0051] Add dimethyl terephthalate (DMT), ethylene glycol (EG) and zinc acetate into the transesterification tank after metering (the molar ratio of EG to DMT is 2.5, and the addition of zinc acetate is 0.05wt% of DMT ), the temperature is raised to 200° C., and the methanol generated by the transesterification reaction is distilled out through the distillation tower on the top of the transesterification tank, and the esterification reaction is terminated when the distilled amount of methanol reaches 90% of the theoretical generation amount.

[0052] 1.2 Polycondensation reaction

[0053] Add the reaction product into the polycondensation tank, and add the pre-configured diethylene glycol isophthalate-5-sodium sulfonate (the addition amount is 0.72mol% of DMT), N,N-dibutyl-2- Glycolamid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com