Waste polyester textile recycling method and system

A technology for textiles and polyester, applied in the field of chemical recycling of polyester textiles, can solve the problems of flammable and explosive methanol, complicated process implementation, etc., and achieve the effects of color improvement, simple process and resource saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

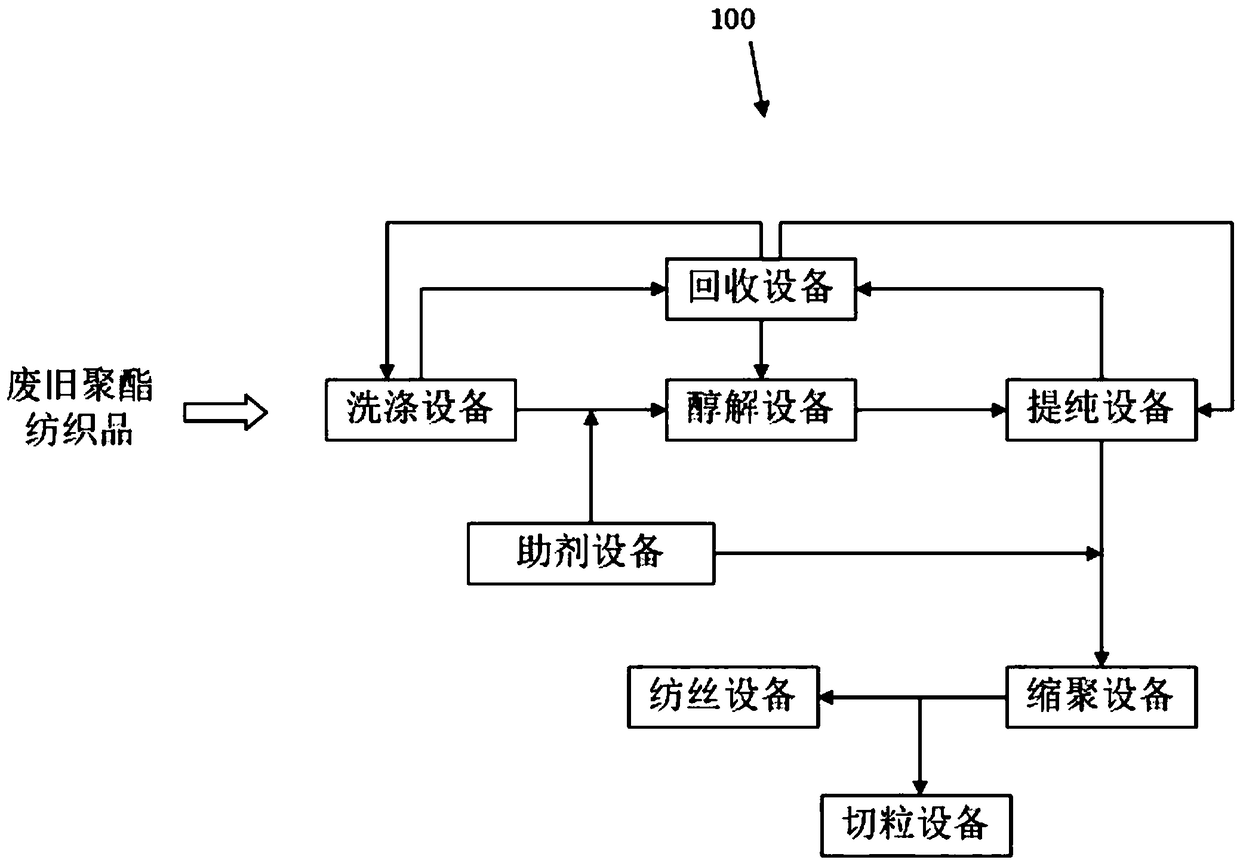

[0031] (1) Waste polyester textile recycling system

[0032] like figure 1 As shown, the waste polyester textile recycling system 100 in this embodiment includes: washing equipment, alcoholysis equipment, purification equipment, polycondensation equipment, pelletizing equipment, spinning equipment, auxiliary equipment and recycling equipment.

[0033] Washing equipment, alcoholysis equipment, purification equipment and polycondensation equipment are connected sequentially through pipelines. The washing equipment has a material conveyor belt, an ethylene glycol spray pipe, and an ethylene glycol waste liquid recovery tank. The alcoholysis equipment has an alcoholysis kettle. The purification equipment has a vacuum distillation kettle, a first dilution kettle, a second dilution kettle and a centrifugal dryer connected in sequence. The polycondensation equipment has prepolymerization tanks and final polymerization tanks connected in sequence.

[0034] The auxiliary agent equi...

Embodiment 2

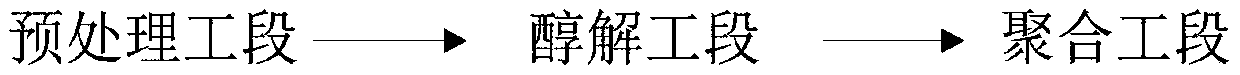

[0047] The method for recycling waste polyester textiles in this embodiment is also carried out by using the waste polyester textile recycling system 100 in Embodiment 1, including the following steps:

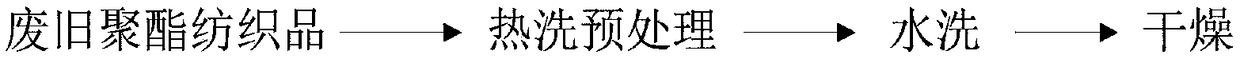

[0048] Step 1, pretreatment section

[0049] Put the waste polyester textiles into the washing equipment, add ethylene glycol and stir for hot washing, the mass ratio of waste polyester textiles to ethylene glycol is 1:2, the mixing time is 30min, the temperature is 130°C, after heating The waste polyester textiles are washed and dried to obtain pretreated textiles.

[0050] Step 2, alcoholysis section

[0051] The pretreated textiles and ethylene glycol are dropped into the alcoholysis kettle according to the mass ratio of 1:1, and then the alcoholysis catalyst zinc acetate is dropped into. The consumption of zinc acetate is 0.2% of the quality of the pretreated textiles, and the reaction temperature is controlled at 190°C, the reaction time is 3h, and the alcoholysis react...

Embodiment 3

[0056] The method for recycling waste polyester textiles in this embodiment is also carried out by using the waste polyester textile recycling system 100 in Embodiment 1, including the following steps:

[0057] Step 1, pretreatment section

[0058] Put the waste polyester textiles into the washing equipment, add ethylene glycol and stir for hot washing, the mass ratio of waste polyester textiles to ethylene glycol is 1:4, the mixing time is 30min, the temperature is 100 ℃, after heating The waste polyester textiles are washed and dried to obtain pretreated textiles.

[0059] Step 2, alcoholysis section

[0060] The pretreated textiles and ethylene glycol are dropped into the alcoholysis kettle according to the mass ratio of 1:1, and then the alcoholysis catalyst zinc acetate is dropped into. The consumption of zinc acetate is 0.4% of the quality of the pretreated textiles, and the controlled reaction temperature is 180°C, the reaction time is 3h, and the alcoholysis reaction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com