Antibacterial textile material and preparation method thereof

A technology of textile materials and raw materials, applied in the field of antibacterial textile materials and their preparation, can solve the problems of unguaranteed antibacterial effect persistence, unsuitability for widespread manufacturing and use, single antibacterial performance, etc., and achieve good oil-proof effect, good bactericidal effect, The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

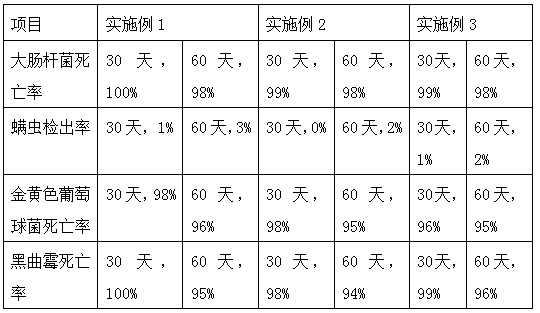

Examples

Embodiment 1

[0024] An antibacterial textile material, comprising the following raw materials in parts by weight: 24 parts of polyester fiber, 16 parts of soybean fiber, 19 parts of bamboo charcoal fiber, 8 parts of epoxy resin, 8 parts of ethyl p-hydroxybenzoate, 17 parts of ethyl orthosilicate Parts, 16 parts of hydroxypropyl methylcellulose, 6 parts of calcium carbonate nanowires, 12 parts of bactericide, 13 parts of adhesive, 12 parts of dispersant, 5 parts of heat stabilizer, and 18 parts of water.

[0025] A preparation method of antibacterial textile material includes the following preparation steps:

[0026] a. Mix polyester fiber, soybean fiber, bamboo charcoal fiber and dispersant, and introduce it into a ball mill for 3 hours to obtain a mixture;

[0027] b. Mix the epoxy resin, ethyl p-hydroxybenzoate, ethyl orthosilicate, hydroxypropyl methyl cellulose, heat stabilizer and water into the reaction kettle, and heat it in a water bath at 120°C to 380r Stir at a speed of 200r / min for 30...

Embodiment 2

[0035] An antibacterial textile material, comprising the following raw materials in parts by weight: 18 parts of polyester fiber, 18 parts of soybean fiber, 15 parts of bamboo charcoal fiber, 8 parts of epoxy resin, 14 parts of ethyl p-hydroxybenzoate, and 13 parts of ethyl orthosilicate Parts, 17 parts of hydroxypropyl methylcellulose, 8 parts of calcium carbonate nanowires, 9 parts of fungicides, 15 parts of adhesives, 7 parts of dispersants, 5 parts of heat stabilizers, and 17 parts of water.

[0036] A preparation method of antibacterial textile material includes the following preparation steps:

[0037] a. Mix polyester fiber, soybean fiber, bamboo charcoal fiber and dispersant, and introduce them into a ball mill for 2h to obtain a mixture;

[0038] b. Mix the epoxy resin, ethyl p-hydroxybenzoate, ethyl orthosilicate, hydroxypropyl methyl cellulose, heat stabilizer and water into the reaction kettle and heat it in a water bath at 120°C to 340r Stir at a speed of 200r / min for 3...

Embodiment 3

[0046] An antibacterial textile material, comprising the following parts by weight of raw materials: 18 parts of polyester fiber, 20 parts of soybean fiber, 15 parts of bamboo charcoal fiber, 13 parts of epoxy resin, 14 parts of ethyl p-hydroxybenzoate, 17 parts of ethyl orthosilicate Parts, 17 parts of hydroxypropyl methylcellulose, 8 parts of calcium carbonate nanowires, 9 parts of fungicides, 15 parts of adhesives, 10 parts of dispersants, 8 parts of heat stabilizers and 17 parts of water.

[0047] A preparation method of antibacterial textile material includes the following preparation steps:

[0048] a. Mix polyester fiber, soybean fiber, bamboo charcoal fiber and dispersant, and introduce it into a ball mill for 3 hours to obtain a mixture;

[0049] b. Mix the epoxy resin, ethyl p-hydroxybenzoate, ethyl orthosilicate, hydroxypropyl methyl cellulose, heat stabilizer and water into the reaction kettle and heat it in a water bath at 140°C to 380r Stir for 40 minutes at a rotation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com