Anion doped high voltage charge and discharge lithium vanadium phosphate cathode material and preparation method thereof

A technology of lithium vanadium phosphate and positive electrode materials, which is applied in the direction of battery electrodes, circuits, electrical components, etc., to achieve the effect of reducing electrical conductivity, reducing contact resistance, and succinct process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

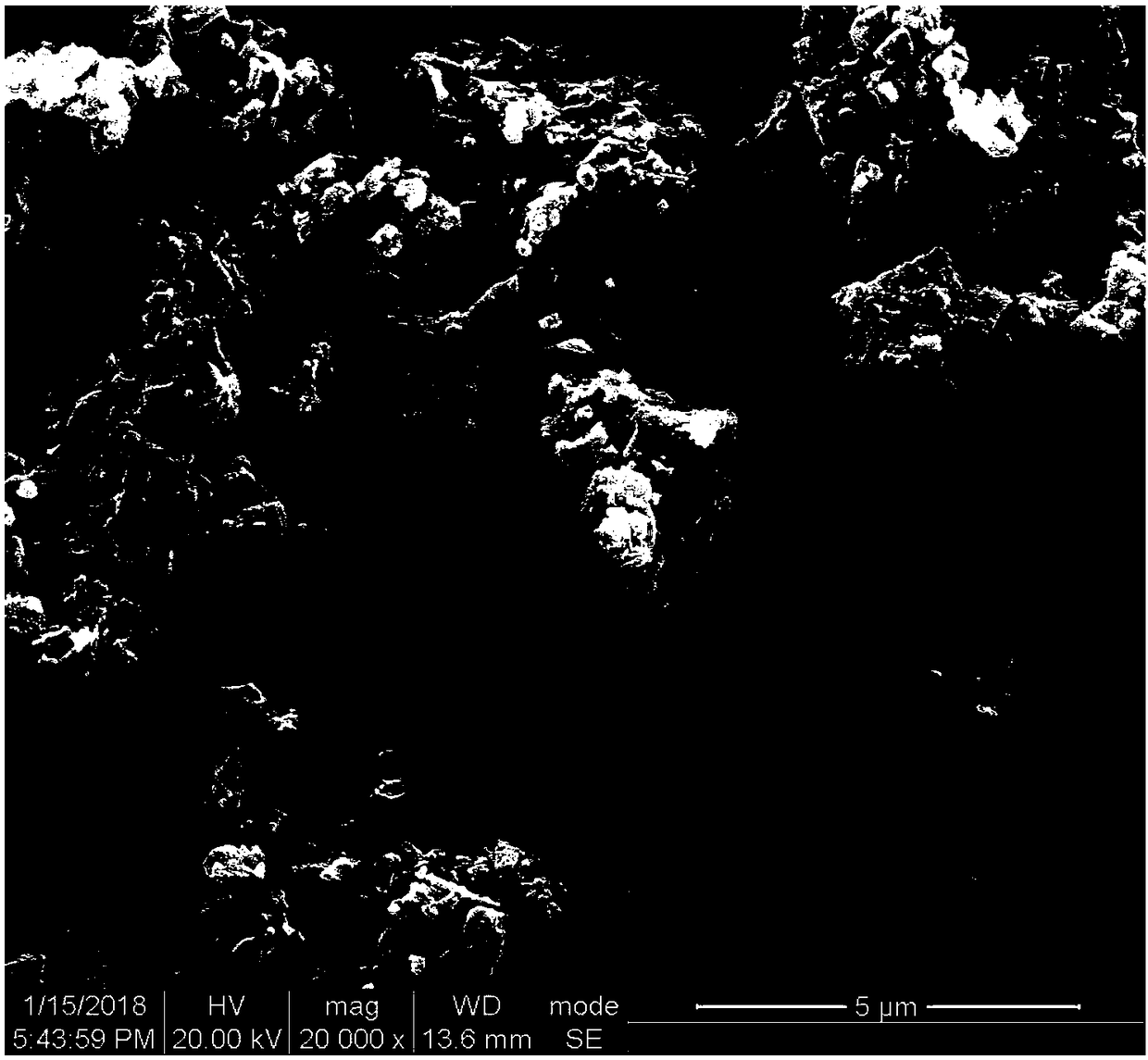

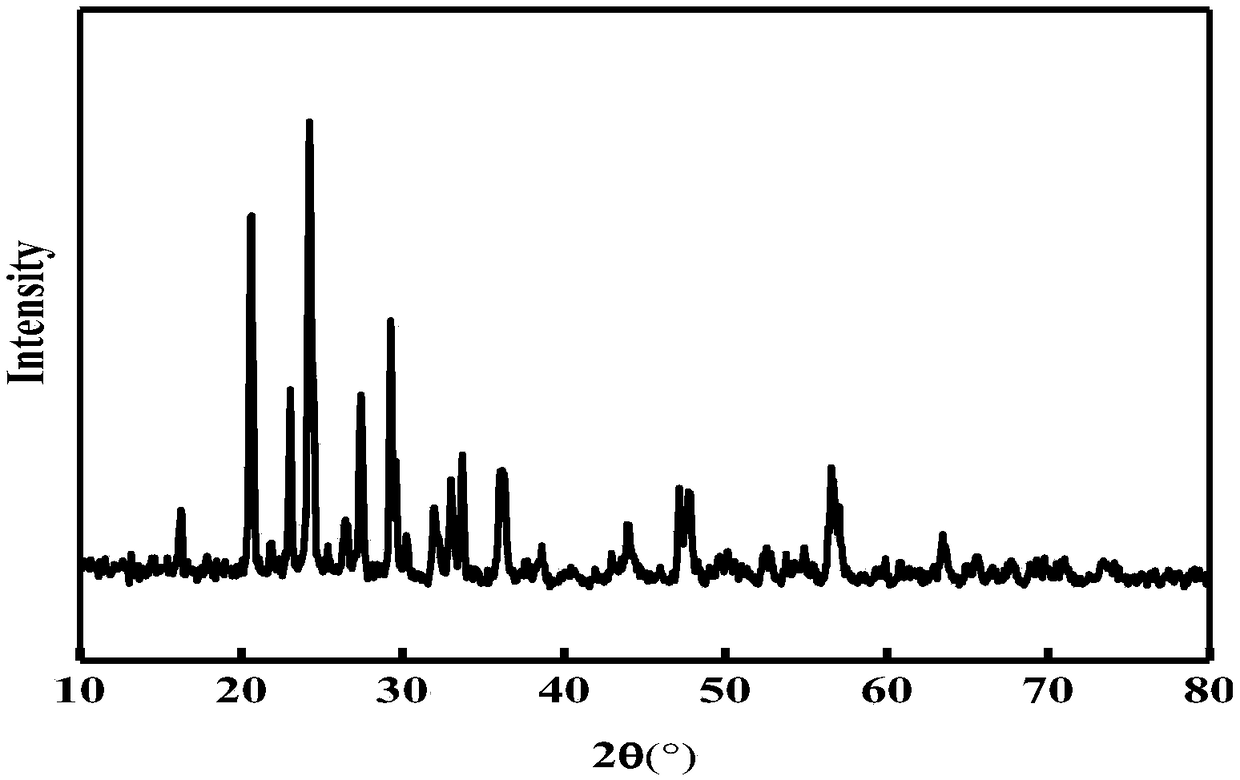

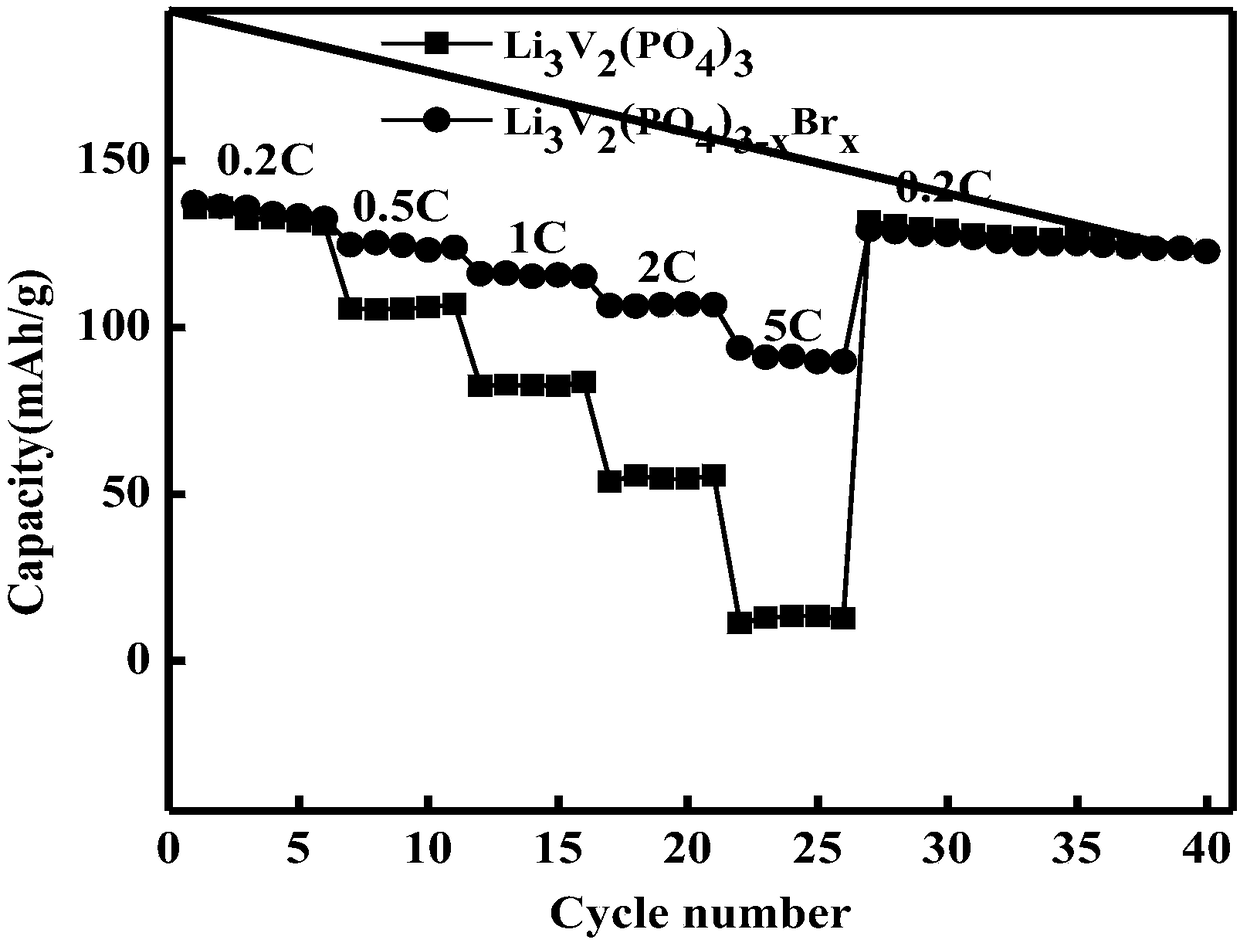

[0023] A preparation method of anion-doped high-voltage charge-discharge lithium vanadium phosphate positive electrode material, the lithium vanadium phosphate positive electrode material is Li 3 V 2 (PO 4 ) 3-x Br x , where 0.04≤x≤0.16, including the following steps:

[0024] 1) will Li 3 C 6 h 6 o 7 , V 2 o 5 、H 3 PO 4 1. Add HBr into deionized water and stir for 5 minutes; slowly add a saturated aqueous solution of oxalic acid to the solution, and continue stirring for 5 minutes, the solution turns orange; use ammonia water to adjust the pH of the solution to PH7, and the solution turns light green at this time;

[0025] 2) Directly heat in a water bath at a heating temperature of 60°C with constant stirring, keep warm for 3 hours to evaporate excess water, and the solution gradually turns into a dark blue sol; put the obtained sol in an oven at 70°C, dry for 10 hours, and evaporate to dryness to obtain a precursor body;

[0026] 3) Put the above-mentioned prod...

Embodiment 2

[0050] A preparation method of anion-doped high-voltage charge-discharge lithium vanadium phosphate positive electrode material, the lithium vanadium phosphate positive electrode material is Li 3 V 2 (PO 4 ) 3-x Br x , where 0.04≤x≤0.16, 1) the Li 3 C 6 h 6 o 7 , V 2 o 5 、H 3 PO 4 1. Add HBr into deionized water and stir for 5 minutes; slowly add a saturated aqueous solution of oxalic acid to the solution, and continue stirring for 5 minutes, the solution turns orange; use ammonia water to adjust the pH of the solution to PH7, and the solution turns light green at this time;

[0051] 2) Directly heat in a water bath at a heating temperature of 50°C with constant stirring, keep warm for 3 hours to evaporate excess water, and the solution gradually turns into a dark blue sol; put the obtained sol in an oven at 70°C, dry for 10 hours and evaporate to dryness to obtain a precursor body;

[0052] 3) Put the above-mentioned obtained product into a tube furnace for pre-ca...

Embodiment 3

[0056] A preparation method of anion-doped high-voltage charge-discharge lithium vanadium phosphate positive electrode material, the lithium vanadium phosphate positive electrode material is Li 3 V 2 (PO 4 ) 3-x Br x , where 0.04≤x≤0.16, 1) the Li 3 C 6 h 6 o 7 , V 2 o 5 、H 3 PO 4 1. Add HBr into deionized water and stir for 5 minutes; slowly add a saturated aqueous solution of oxalic acid to the solution, and continue stirring for 5 minutes, the solution turns orange; use ammonia water to adjust the pH of the solution to PH7, and the solution turns light green at this time;

[0057] 2) Directly heat in a water bath at a heating temperature of 65°C with constant stirring, keep warm for 3 hours to evaporate excess water, and the solution gradually turns into a dark blue sol; put the obtained sol in an oven at 80°C, dry for 10 hours and evaporate to dryness to obtain a precursor body;

[0058] 3) Put the above-mentioned product into a tube furnace for pre-calcination...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com