A method for extracting molybdenum and rhenium from rhenium-containing molybdenum concentrate

A molybdenum concentrate and extraction technology is applied in the field of extracting molybdenum and rhenium from rhenium-containing molybdenum concentrate, which can solve the problems of large environmental pollution and low recovery rate, reduce the harm of lead, reduce the generation of smoke and dust, and reduce the content of impurities Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

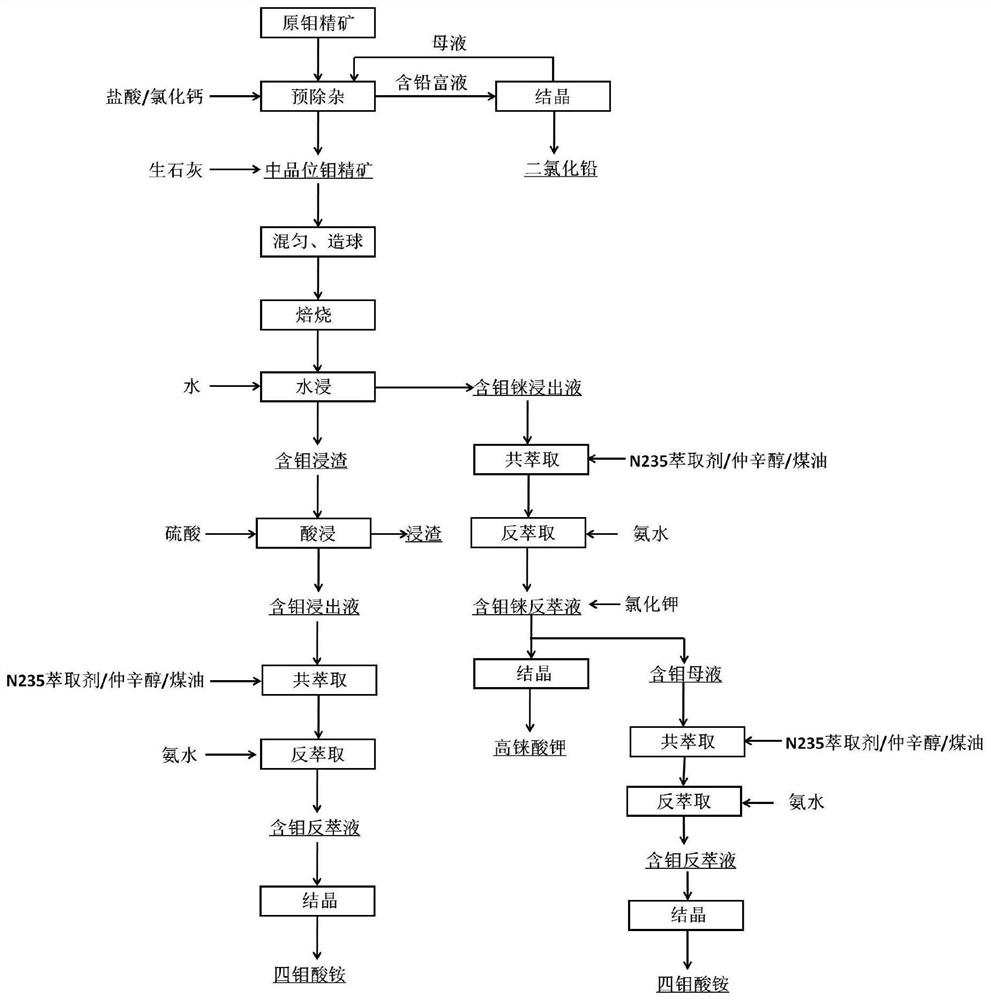

[0093] A method for extracting molybdenum and rhenium from rhenium-containing molybdenum concentrate, see figure 1 , follow the steps below:

[0094] (1) Pretreatment process

[0095] Add molybdenum concentrate, calcium chloride and hydrochloric acid in the same container, the mass ratio of the calcium chloride to the molybdenum concentrate is 4:10, the mass concentration of the hydrochloric acid is 8%, and the solid-liquid mass ratio is 1.2 : 5, then the container is put into a constant temperature water bath with constant temperature stirring and immersion, the immersion temperature is 93 ℃, and the immersion time is 50min, after the stirring stops, suction filtration while hot is obtained to obtain filter cake and filtrate, The filtrate is crystallized to precipitate lead dioxide, and the filter cake is washed several times with distilled water at the same temperature and then dried to obtain medium-grade molybdenum concentrate, and the removal rate of lead has reached 92....

Embodiment 2

[0112] A method for extracting molybdenum and rhenium from rhenium-containing molybdenum concentrate is carried out according to the following steps:

[0113] (1) Pretreatment process

[0114] Add molybdenum concentrate, calcium chloride and hydrochloric acid in the same container, the mass ratio of the calcium chloride to the molybdenum concentrate is 1:10, the mass concentration of the hydrochloric acid is 6%, and the solid-liquid mass ratio is 0.5 : 5, then the container is put into a constant temperature water bath with constant temperature stirring and immersion, the immersion temperature is 90 ℃, and the immersion time is 40min, after the stirring stops, suction filtration while hot is obtained to obtain filter cake and filtrate, The filtrate is crystallized to precipitate lead dioxide, and the filter cake is washed several times with distilled water at the same temperature and then dried to obtain medium-grade molybdenum concentrate, and the removal rate of lead has rea...

Embodiment 3

[0131] A method for extracting molybdenum and rhenium from rhenium-containing molybdenum concentrate is carried out according to the following steps:

[0132] (1) Pretreatment process

[0133] Add molybdenum concentrate, calcium chloride and hydrochloric acid in the same container, the mass ratio of the calcium chloride to the molybdenum concentrate is 5:10, the mass concentration of the hydrochloric acid is 12%, and the solid-liquid mass ratio is 1.5 : 5, then the container is put into a constant temperature water bath with constant temperature stirring and immersion, the immersion temperature is 95 ℃, and the immersion time is 60min, after the stirring stops, suction filtration while hot is obtained to obtain filter cake and filtrate, The filtrate is crystallized to precipitate lead dioxide, and the filter cake is washed several times with distilled water at the same temperature and then dried to obtain a medium-grade molybdenum concentrate, and the removal rate of lead has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com