Extraction and crystallization process of 5-oxomilbemycins fermentation liquor

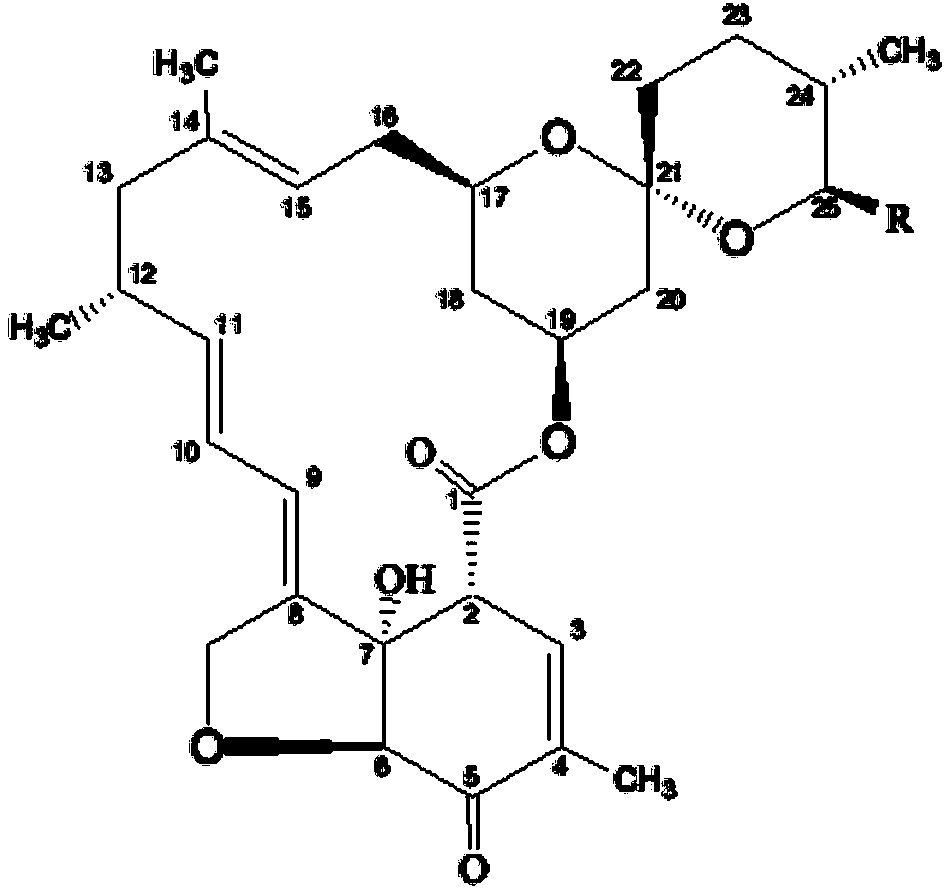

A technology of ketomilbemycin and fermented liquid, which is applied in the field of extraction and crystallization process of 5-ketomilbemycin fermented liquid, can solve the problem of no relevant reports on extraction and separation process and crystallization process, low purity of crude extract, Complicated operation process and other problems to achieve the effect of overcoming the extreme instability of intermediates, high yield and reducing impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1: Preparation of 5-ketomilbemycin fermented liquid

[0041] 5-ketomilbemycin-producing bacteria Streptomyces milbemycinicus F2-18 is a genetically engineered bacterium obtained by Streptomyces milbemycinicus (Streptomyces milbemycinicus, deposit number: CGMCC No. 7677) through genetic recombination technology, references Huang Jun, Lin Jiatan, Zhou Min et al. Knockout of Streptomyces hygroscopicus HS023milF gene to construct genetically engineered bacteria producing 5-ketomilbemycin. "Acta Microbiology", 2015,55(1):107-113. The method of using the engineering bacteria to prepare 5-ketomilbemycin fermentation broth refers to the invention patent CN201310541829.8.

[0042] 1. Take Streptomyces F2-18 spore suspension from the cryopreservation tube and inoculate it on a plate of solid MS medium (mannitol 20g / L, soybean powder 20g / L, agar 20g / L), and culture at 28°C for 7 days;

[0043] 2. Inoculate the cultured fungal spores into a 15L seed tank with 10L of see...

Embodiment 2

[0050] Embodiment 2: the ethanol extraction of 5-ketomilbemycin fermented liquid

[0051] 1) After getting 12.5L of 5-ketomilbemycin fermented liquid among the embodiment 1 and passing through the frame filter, collect and obtain mycelium 5.2Kg;

[0052] 2) 5.2Kg of mycelium was soaked in 26L of 98% ethanol, and 25.6L of 5-ketomilbemycin extract was obtained after plate and frame filtration, concentrated at a negative pressure of 0.09Mpa until the volume concentration of ethanol was 50%, and 5-ketomilbemycin was obtained. Ketomilbemycin ethanol concentrate 12.7L;

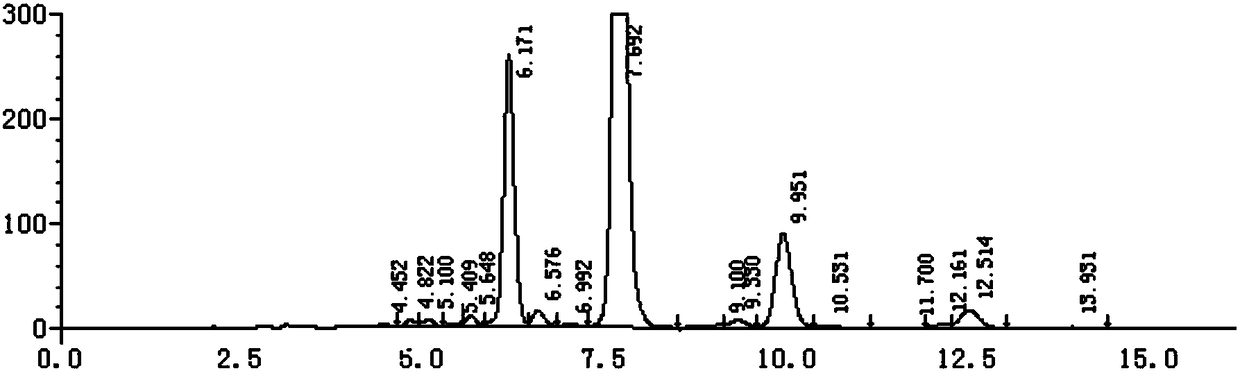

[0053] 3) Take 12.7 L of the 5-ketomilbemycin ethanol concentrate and extract and layer with 12.7 L of n-heptane to obtain 12.0 L of n-heptane phase. Detection by HPLC (see figure 1 ), the measured concentration of 5-ketomilbemycin A3 is 520mg / L, HPLC purity 19.3%, the concentration of A4 is 2002mg / L, HPLC purity 59.2%.

Embodiment 3

[0054] Example 3: The methanol extraction of 5-ketomilbemycin fermentation broth

[0055] 1) After 12.5 L of 5-ketomilbemycin fermentation broth in Example 1 was filtered through a plate frame, 5.2 Kg of mycelium was collected;

[0056] 2) 5.2Kg of mycelium was soaked in 26L of 98% methanol, and 25.6L of 5-ketomilbemycin extract was obtained after plate and frame filtration, concentrated at a negative pressure of 0.09Mpa until the volume concentration of methanol was 50%, and 5-ketomilbemycin was obtained. Ketomilbemycin Methanol Concentrate 12.7L;

[0057] 3) Take 12.7 L of 5-ketomilbemycin methanol concentrate and extract and separate with 12.7 L of n-heptane to obtain 12.2 L of n-heptane phase. Adopt HPLC detection, record the concentration of 5-ketomilbemycin A3 to be 510mg / L, the concentration of A4 is 1970mg / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com