Method for combined anaerobic treatment of swine wastewater by using sepiolite and biomass charcoal

A biochar and anaerobic treatment technology, applied in anaerobic digestion treatment, chemical instruments and methods, water/sewage treatment, etc., can solve the problems of high energy consumption, large land occupation environment, and many mechanical equipment, etc., to achieve Improvement of COD and ammonia nitrogen removal rate, increase of adsorption capacity, and increase of pore volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

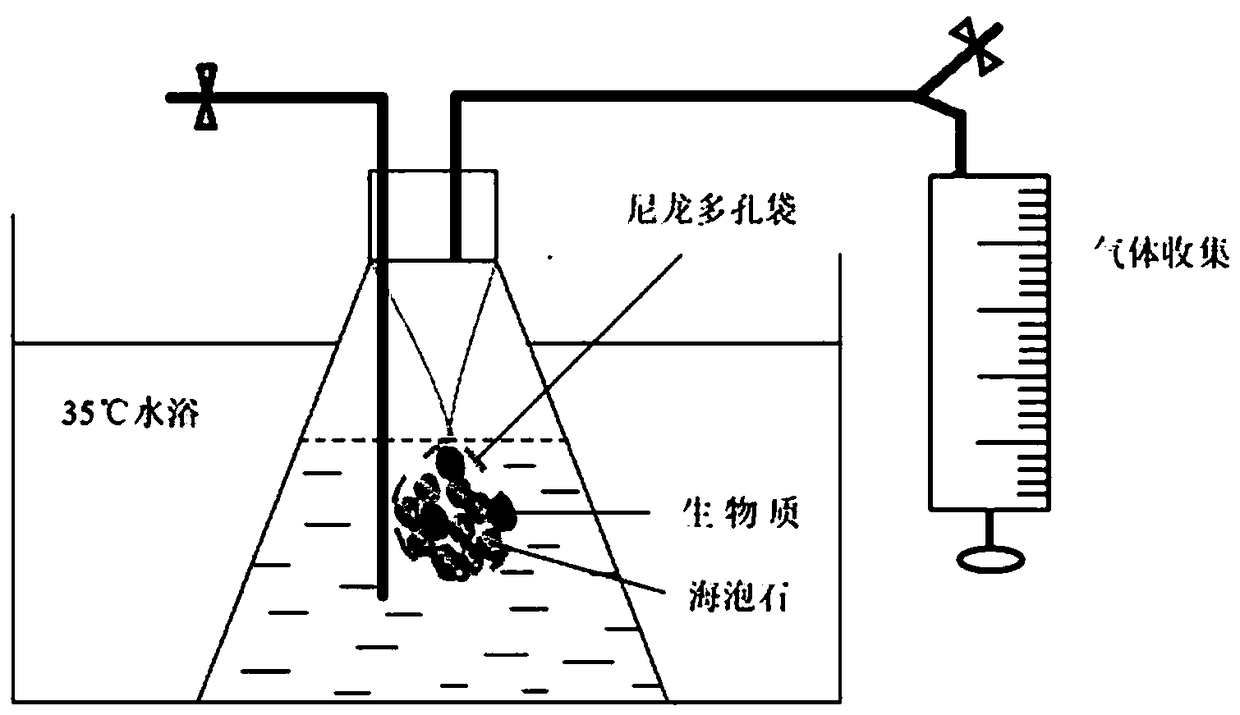

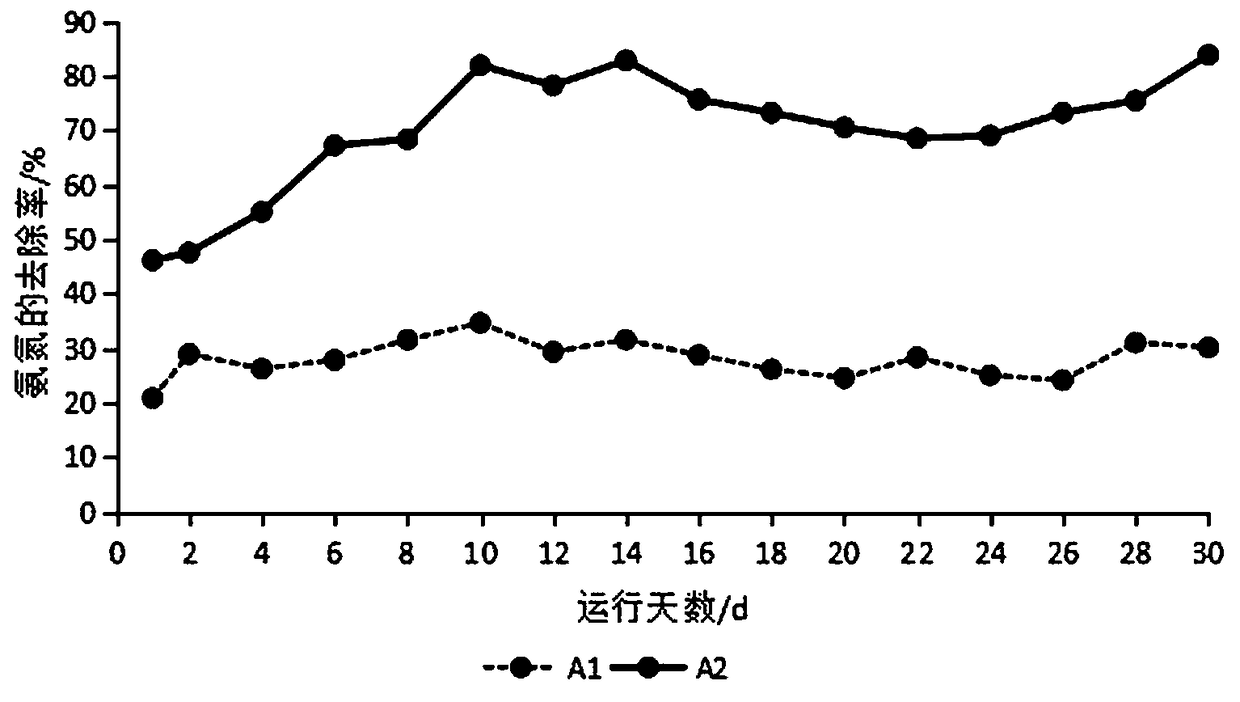

Method used

Image

Examples

Embodiment 1

[0021] (1) Preparation of biochar

[0022] The raw material of biochar in this example comes from discarded melon seed shells from a food processing factory in Liaoning Province. Take 1000-1500mL of distilled water and 100g of dried melon seed peel powder, respectively, with a solid-to-liquid ratio of 10%-15%, and add them to the reaction kettle. After the melon seed peel is fully swollen, seal the reaction kettle. Put the reaction kettle in a digital blast drying oven, keep it for 4 hours after the temperature rises to 190-200°C, the heating rate is about 6°C / min, stop heating and take it out, and cool the reaction kettle with cold water, and wait for the reaction kettle to cool to room temperature Finally, unscrew the release valve to release air, then slowly open the reaction kettle, perform centrifugal filtration, and dry the residue and solid product after suction filtration at 105°C for 24 hours to obtain melon seed shell biochar.

[0023] (2) Preparation of thermally m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com