Preparation method of biomass boron nitride nanosheet modified polyimide aerogel

A technology of polyimide and boron nitride, which is applied in the field of preparation of biomass boron nitride nanosheets modified polyimide aerogels, can solve the problem of slow energy exchange rate between phase change materials and the outside world, aerogels Poor mechanical strength, poor thermal conductivity and other problems, to achieve excellent light-to-heat conversion performance, improve thermal conductivity, and improve mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] This embodiment one discloses a preparation method of biomass boron nitride nanosheet modified polyimide airgel, comprising the following steps:

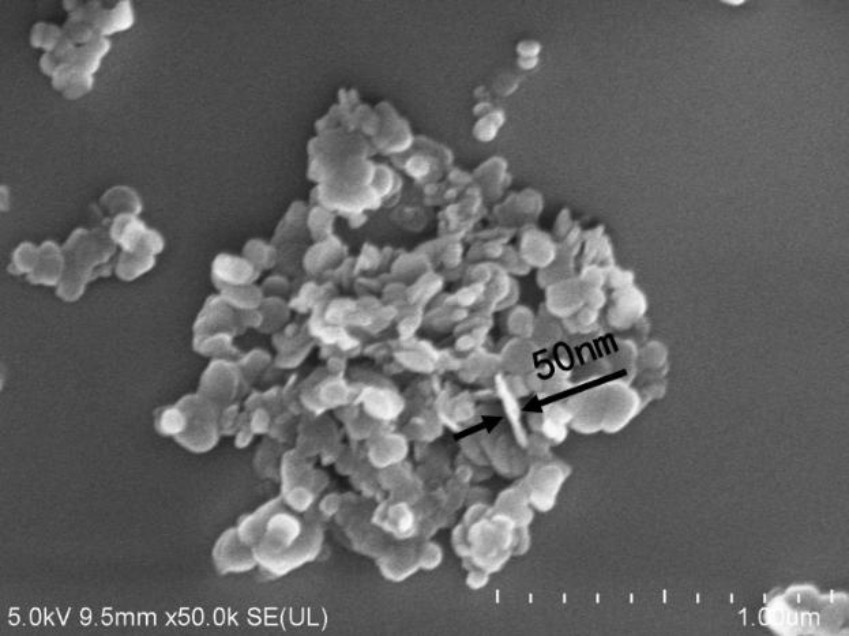

[0048] Step A1: first add 1 g sodium lignosulfonate to 50 mL deionized water, and disperse it evenly under ultrasonic treatment with a power of 300 W for 2 minutes, then add 1 g hexagonal boron nitride and stir for a while, then perform ultrasonic stripping in a water bath, which is used for ultrasonic stripping in a water bath The ultrasonic power is 300 W, the temperature is 25 °C, and the time is 12 h; after the ultrasonic stripping in the water bath is completed, the obtained boron nitride suspension is poured into a preset centrifuge tube for centrifugation to remove the unstripped bulk nitride. Boron particles were centrifuged at a rate of 2500 r / min, time of 15 min, and temperature of 20°C to prepare a suspension of modified boron nitride nanosheets, which was finally placed in low-temperature refrigeration for later us...

Embodiment 2

[0054] This embodiment 2 discloses a preparation method of biomass boron nitride nanosheet modified polyimide airgel, comprising the following steps:

[0055] Step A1: First add 1 g of acid-type sophorolipids into 50 mL of deionized water, and disperse it evenly under ultrasonic treatment with a power of 200W for 5 minutes, then add 2 g of hexagonal boron nitride and stir for a while, then perform ultrasonic peeling in a water bath The ultrasonic power used was 300 W, the temperature was 25 °C, and the time was 6 h; after the water bath ultrasonic stripping was completed, the obtained boron nitride suspension was poured into a preset centrifuge tube for centrifugation to remove the unstripped bulk nitrogen. The boron nitride particles were centrifuged at a rate of 3000 r / min, a time of 15 min, and a temperature of 25°C to prepare a suspension of modified boron nitride nanosheets, which was finally stored in low temperature storage for later use.

[0056] Step A2: First, add 0....

Embodiment 3

[0061] This embodiment three discloses a preparation method of biomass boron nitride nanosheet modified polyimide airgel, comprising the following steps:

[0062] Step A1: First add 1 g of sodium rosin sulfonate to 100 mL of deionized water, and disperse it evenly under ultrasonic treatment at a power of 300 W for 10 minutes, then add 2 g of hexagonal boron nitride and stir for a while, then perform ultrasonic peeling in a water bath, and ultrasonic peeling in a water bath The ultrasonic power used was 500 W, the temperature was 25 °C, and the time was 24 h; after the water bath ultrasonic stripping was completed, the obtained boron nitride suspension was poured into a pre-set centrifuge tube for centrifugation to remove the unstripped large particles. Block boron nitride particles were centrifuged at a rate of 2000 r / min, time of 15 min, and temperature of 20°C to prepare a suspension of modified boron nitride nanosheets, which was finally stored in low temperature storage for...

PUM

| Property | Measurement | Unit |

|---|---|---|

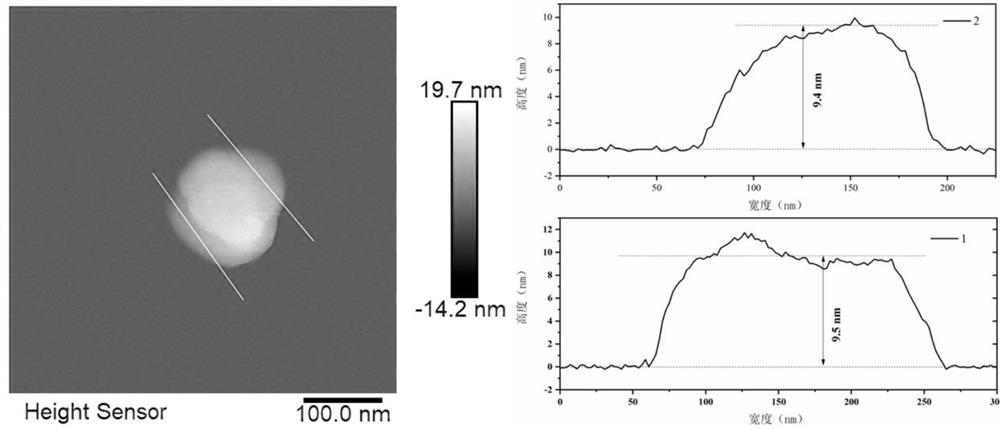

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com