SCR urea spraying system for dimethyl ether engine

A technology of urea injection system and dimethyl ether, which is applied in the direction of engine components, combustion engines, machines/engines, etc., can solve the problems of high processing cost, complicated control process, and many parts, and achieve system cost reduction and system structure simplification , Optimize the effect of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

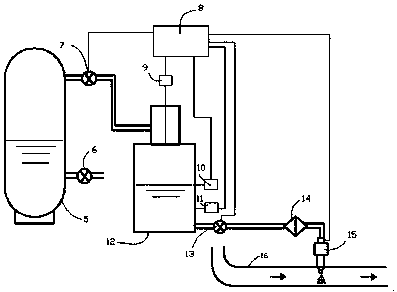

[0012] A kind of SCR urea injection system that is used for dimethyl ether engine of the present invention, the working principle of its embodiment is as follows figure 1 shown. The urea solution is stored in the urea solution tank 12, and under the action of the saturated vapor pressure of dimethyl ether, the solution flows into the urea nozzle 15 through the urea tank switch valve 13 and the filter 14. The urea tank 12 in this embodiment is a pressure vessel with a volume of about 35L; a pressure sensor 9 is arranged on the urea tank 12 to measure the pressure of the urea solution and feed back to the electronic control unit; a liquid level sensor 10 is also installed on the urea tank , to measure the liquid level of the urea solution; a temperature sensor 11 is installed on the urea tank to measure the temperature of the urea solution and feed it back to the electronic control unit.

[0013] The urea nozzle 15 is a high-speed electromagnetic valve, its opening and closing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com