Solvent-free graphene oxide-glass flake anticorrosive coating and preparation method thereof

A technology for glass flakes and anti-corrosion coatings, applied in anti-corrosion coatings, epoxy resin coatings, polyurea/polyurethane coatings, etc., can solve problems such as affecting the shielding efficiency of glass flakes, increasing the difficulty of repairing and grinding, and hard glass flakes. Long-term and more effective anti-corrosion ability, easy repair and grinding, and the effect of reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

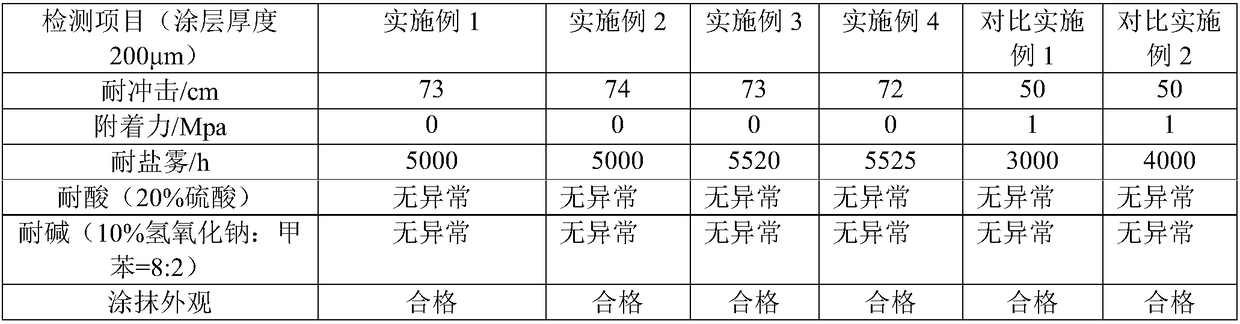

Examples

Embodiment 1

[0024] A kind of preparation of solvent-free graphene oxide-glass flake anticorrosion coating, A component prepares raw material by following mass parts: the weight part of the glass flake of graphene oxide modification is 15 parts, the weight part of epoxy resin is 30 parts, 8 parts by weight of water-based polyurethane resin, 0.5 parts by weight of castor oil, 5 parts by weight of reactive diluent, 25 parts by weight of aluminum tripolyphosphate, 20 parts by weight of titanium dioxide, and 20 parts by weight of defoaming agent 0.2 parts.

[0025] The preparation method of the glass flakes modified by graphene oxide in the A component comprises the steps:

[0026] (1) Mix 98% concentrated sulfuric acid and 30% hydrogen peroxide at a volume ratio of 7:3 to prepare a Piranha solution; then, place the glass scales in acetone, ethanol and distilled water for five minutes for ultrasonic cleaning, take them out and dry them ; then immerse the cleaned and dried glass flakes in Pira...

Embodiment 2

[0035] A kind of preparation of solvent-free graphene oxide-glass flake anticorrosion coating, A component prepares raw material by following mass parts: the weight part of the glass flake of graphene oxide modification is 18 parts, the weight part of epoxy resin is 40 parts, 15 parts by weight of water-based polyurethane resin, 1 part by weight of castor oil, 10 parts by weight of reactive diluent, 12 parts by weight of aluminum tripolyphosphate, 12 parts by weight of titanium dioxide, and 1 part by weight of defoaming agent The parts by weight are 0.5 parts.

[0036] The preparation method of the glass flakes modified by graphene oxide in the A component comprises the steps:

[0037] (1) Mix 98% concentrated sulfuric acid and 30% hydrogen peroxide at a volume ratio of 7:3 to prepare a Piranha solution; then, place the glass scales in acetone, ethanol and distilled water for five minutes for ultrasonic cleaning, take them out and dry them ; then immerse the cleaned and dried g...

Embodiment 3

[0046] A kind of preparation of solvent-free graphene oxide-glass flake anticorrosion coating, A component prepares raw material by following mass parts: the weight part of the glass flake of graphene oxide modification is 25 parts, the weight part of epoxy resin is 35 parts, 13 parts by weight of water-based polyurethane resin, 0.8 parts by weight of castor oil, 8 parts by weight of reactive diluent, 20 parts by weight of aluminum tripolyphosphate, 15 parts by weight of titanium dioxide, and 15 parts by weight of defoaming agent The parts by weight are 0.4 parts.

[0047] The preparation method of the glass flakes modified by graphene oxide in the A component comprises the steps:

[0048] (1) Mix 98% concentrated sulfuric acid and 30% hydrogen peroxide at a volume ratio of 7:3 to prepare a Piranha solution; then, place the glass scales in acetone, ethanol and distilled water for five minutes for ultrasonic cleaning, take them out and dry them ; then immerse the cleaned and d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com