ABS containing phosphogypsum modified with a novel silane coupling agent containing hindered phenol and a preparation method thereof

A technology of silane coupling agent and hindered phenol, which is applied in the field of modified ABS and its preparation, can solve the problem of not being able to suppress the breakage of polyene molecular chains, the difficulty of dispersing antioxidants and inorganic fillers, and the problems of antioxidants and inorganic fillers. Fillers are difficult to mix evenly, so as to reduce the surface energy, avoid uneven dispersion and reduce the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Benzyl chloride hindered phenol The preparation method is the same as CN104744813A.

[0022] (2) Synthesis of a new type of silane coupling agent for hindered phenol: in N 2 Under protection, add 10 parts of the above synthetic benzyl chloride hindered phenol, 5 parts of dimethyl sulfoxide, and 10 parts of diethylaminomethyl triethoxy into a 250mL three-necked flask equipped with mechanical stirring, condenser and thermometer. Silane Raise the oil temperature to 80℃, react for 10-48h, wash with 20 parts of petroleum ether, vacuum dry at 30℃ for 12h to obtain the hindered phenol new silane coupling agent, fractionate and recover the solvent, label it as hindered phenol new silane coupling agent 1

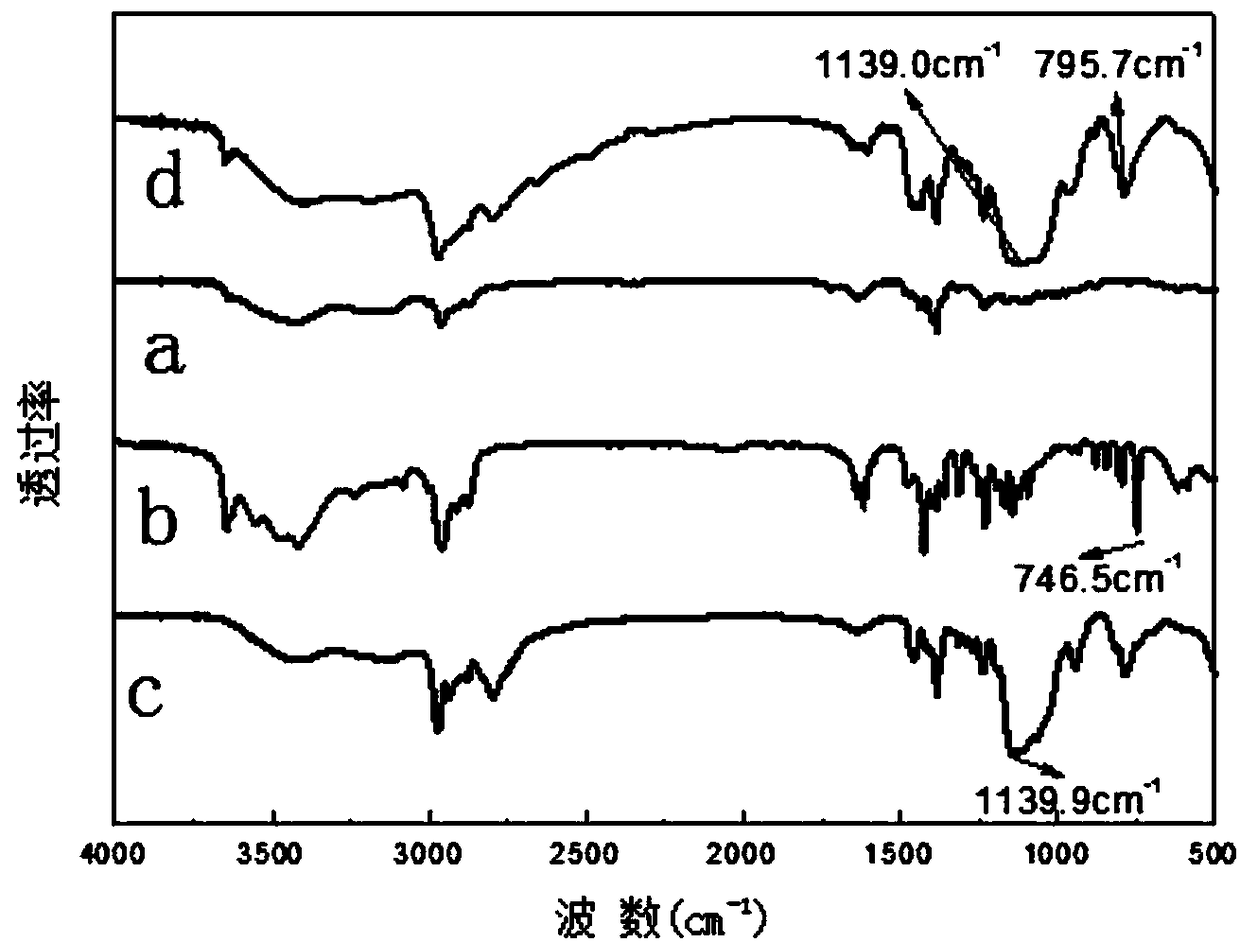

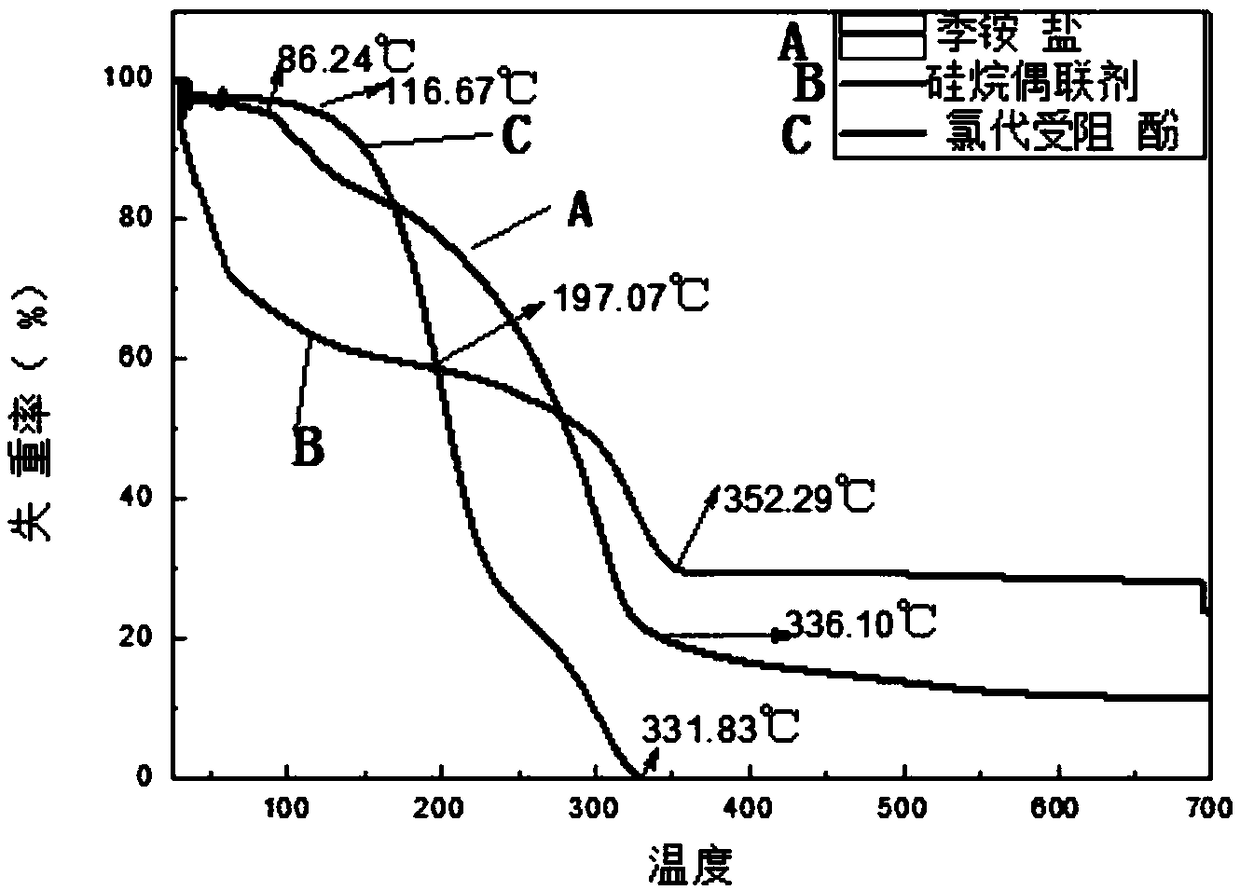

[0023] Infrared analysis of the synthesized hindered phenol new silane coupling agent (FT-IR, figure 1 ) And thermogravimetry (TG, figure 2 )analysis. Correct figure 1 Conduct analysis by figure 1 The curves a and b show that the wave number is 2980cm -1 The peaks on the l...

Embodiment 2

[0030] The difference between this example and Example 1 is that in the synthesis step (1) of the hindered phenol novel silane coupling agent 1, the temperature is changed to 90°C, the reaction time is 8h, and the diethylaminomethyltriethoxysilane is changed to 12 parts, 10 parts of solvent, 40 parts of petroleum ether. The vacuum drying temperature is 25°C, and the drying time is 14h; (2) The processing ingredients are changed to 30 parts by mass of phosphogypsum by adding 0.25 parts of a hindered phenol new silane coupling agent, and the modification process is 70°C high-speed stirring for 20 minutes.

[0031] See Table 1 for resistance to thermal oxidative aging. It can be seen from Table 1 that ABS with 0.25 parts of hindered phenol new silane coupling agent modified phosphogypsum has a slight increase in melt index after different times of extrusion, but there is little change, indicating that the molecular chain of ABS is slightly different. Fracture, but will not affect i...

Embodiment 3

[0034] The difference between this implementation and Example 1 is that in the synthesis step (1) of the hindered phenol novel silane coupling agent 1, the temperature is changed to 100°C, the reaction time is 12h, and the amount of diethylaminomethyltriethoxysilane is 15 parts. , The solvent is changed to 20 parts of toluene and 50 parts of petroleum ether. The vacuum drying temperature is 45℃ and the drying time is 10h; (2) The processing ingredients are changed to 30 parts by mass of phosphogypsum by adding 0.1 part of hindered phenol new silane coupling agent 1, and the modification process is 80℃ and high-speed stirring for 25 minutes .

[0035] See Table 1 for resistance to thermal oxidative aging. It can be seen from Table 1 that after adding 0.1 part of hindered phenol new silane coupling agent 1 modified phosphogypsum, the melt index of ABS increased slightly after being extruded for different times, but the change was not large, indicating that the molecular chain of A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com