HFCVD batch preparation method of complex-shaped diamond-coated cutter

A complex shape, diamond thin film technology, applied in the direction of metal material coating process, coating, gaseous chemical plating, etc., can solve the difficulty, poor thermal conductivity, unsuitable CVD diamond coating complex shape cemented carbide tool batch preparation device and other issues to achieve the effect of ensuring uniform deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

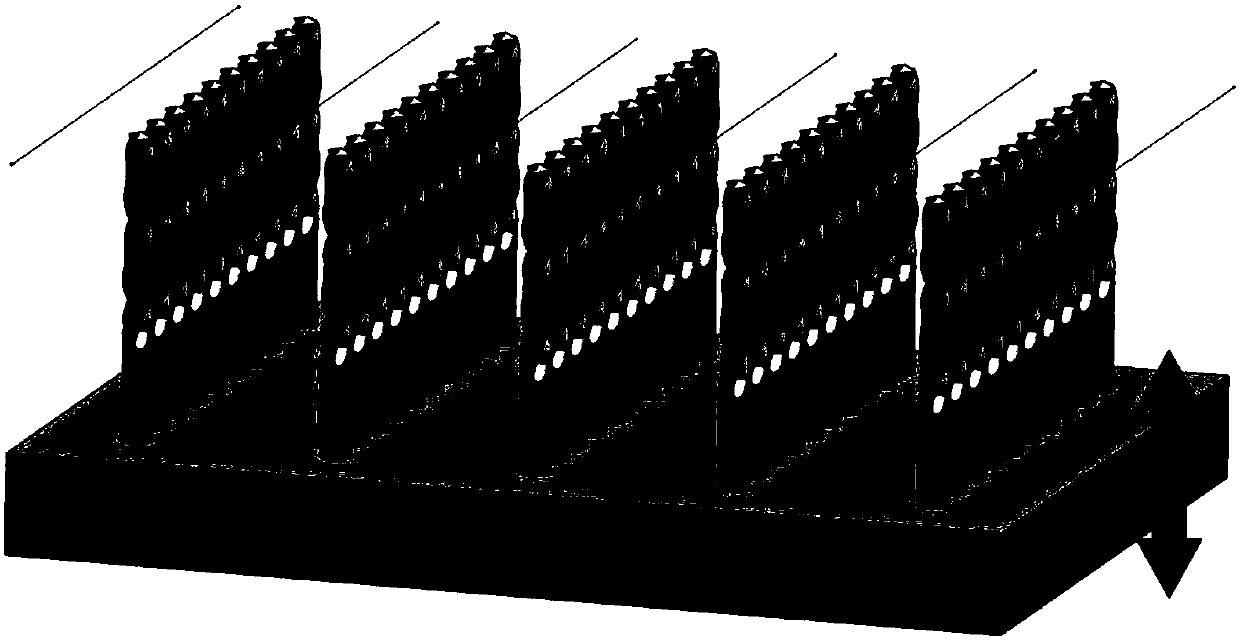

[0038] Such as figure 1 As shown, a CVD diamond coating is coated on a milling cutter for machining graphite, and the diameter of the shank is The blade length is 30mm, and the overall length of the tool is 100mm. The structure of the tool cooling base used in this embodiment is as follows: the size of red copper is 20×60×120 mm in height, width and length, the size of stainless steel is 30×60×120 mm in height, width and length, and the thickness is 0.4 mm. 60×120mm, 40 drills are evenly spaced on the tool cooling base hole (hole depth 40mm), in order to install and insert 40 milling cutters upright. The molybdenum sheet covers the copper layer and the stainless steel layer. In the present invention, the role of the molybdenum sheet is to prevent the reaction group from reaching the lower tool handle through its precise inner surface of the drilled hole and closely cooperate with the tool handle to prevent the "black rod" phenomenon; in addition, the molybdenum sheet has ...

Embodiment 2

[0061] The present embodiment is the same as embodiment 1, the difference is:

[0062] The tool cooling base used has a 3-layer structure: molybdenum sheet + graphite + stainless steel; the third step, single-layer diamond film deposition: after the reaction chamber is evacuated, the reaction gas (hydrogen and acetone) is introduced, and the single-layer diamond film is started after adjusting the pressure of the reaction chamber For the deposition of CVD diamond coating, the process parameters are: pressure 25 Torr, total gas flow rate 1000 ml / min, acetone / hydrogen (volume ratio) 2.6%, tantalum wire temperature about 2100 ° C, after 3 hours of deposition, the deposition on the blade A diamond coating about 6-8 microns thick was obtained. Rotate the position of each tool 5 by 90 degrees, and use the same process parameters for another 3 hours of deposition to obtain a diamond coating with a thickness of about 12-16 microns, which can effectively ensure the uniformity of the co...

Embodiment 3

[0064] The present embodiment is the same as embodiment 1, the difference is:

[0065] This embodiment adopts image 3 In the 4-layer tool cooling base shown in B, the uppermost molybdenum sheet layer 1 and the lower cooling base (graphite layer 6 + copper layer 2 + stainless steel layer 3) form a certain hollow space, and the graphite size is high, wide, The length is 15×60×120mm, the size of red copper is 10×60×120mm in height, width and length, the height, width and length of stainless steel are 20×60×120mm, and the molybdenum sheet 1 with a thickness of 0.4mm is cut into 60×120mm. Drill 40 evenly spaced holes in the tool cooling base hole (hole depth 40mm), in order to install and insert 40 milling cutters upright.

[0066] Using the same deposition parameters as in Example 1, a 10-12 micron thick micron-nano composite diamond film coating is finally obtained, and the coating uniformity can be effectively ensured. The milling cutter is used for graphite processing, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com