Pulping reaction device and application thereof

A reaction device and refining technology, applied in application, fertilization device, chemical/physical/physical-chemical stationary reactor, etc., can solve the problem of small collision probability of reaction molecules, slow reaction speed of desulfurization regeneration and chemical degradation, and reaction liquid and chemical degradation. Problems such as limited contact area of solid particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

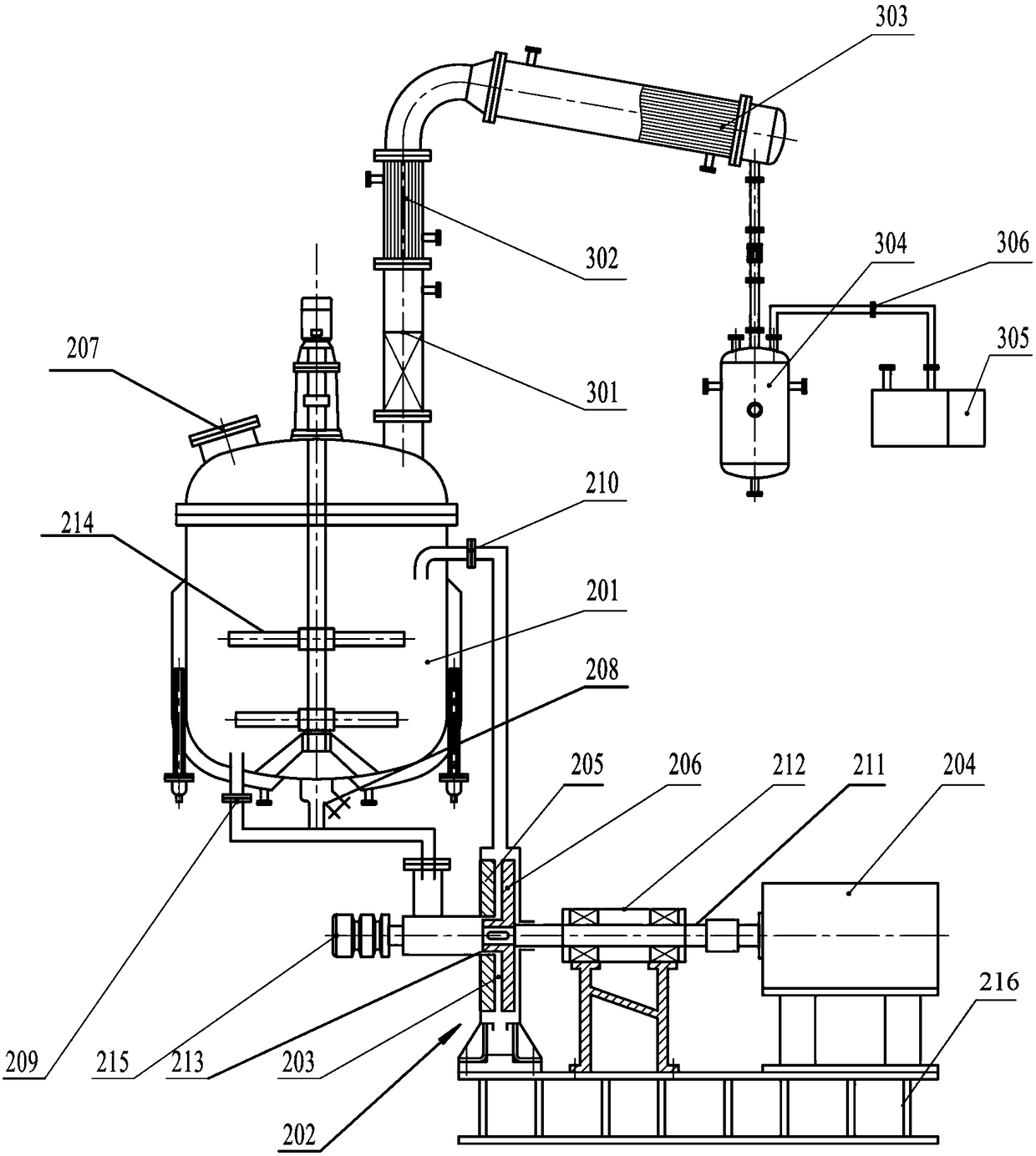

[0217] This embodiment provides a refining reaction device, such as figure 1 As shown, it includes an external refining reaction kettle, the external refining reaction kettle includes a second kettle body 201 and a refining device 202, and the refining device 202 includes a base 216, a refining chamber 203, a second motor 204, a second The auxiliary grinding disc 205 and the second main grinding disc 206, the refining chamber 203 and the second motor 204 are all fixedly connected to the refining base 216, and the second kettle body 201 is provided with a second material inlet 207 and a second material outlet 208 , the kettle body slurry outlet 209 and the kettle body slurry inlet 210, the second feed inlet 207 is provided with a second feed valve, the second outlet 208 is provided with a second discharge valve, the kettle body slurry outlet A slurry valve is provided at 209, a slurry inlet valve is provided at the slurry inlet 210 of the kettle body, the second auxiliary grind...

Embodiment 2

[0223] This embodiment is an embodiment further improved on Embodiment 1, which includes all the content of Embodiment 1, that is, the refining reaction device provided in this embodiment includes all the structural features of the refining reaction device in Embodiment 1, and the improvement is that :

[0224] In the refining reaction device provided in this example, 8 external refining reactors in Example 1 are connected in series, and then 3 parallel conventional reactors are connected. When each external refining reactor is connected in series, each The vacuum negative pressure of the external refining reactor prevents overflow, so as to realize automatic feeding and discharging

Embodiment 3

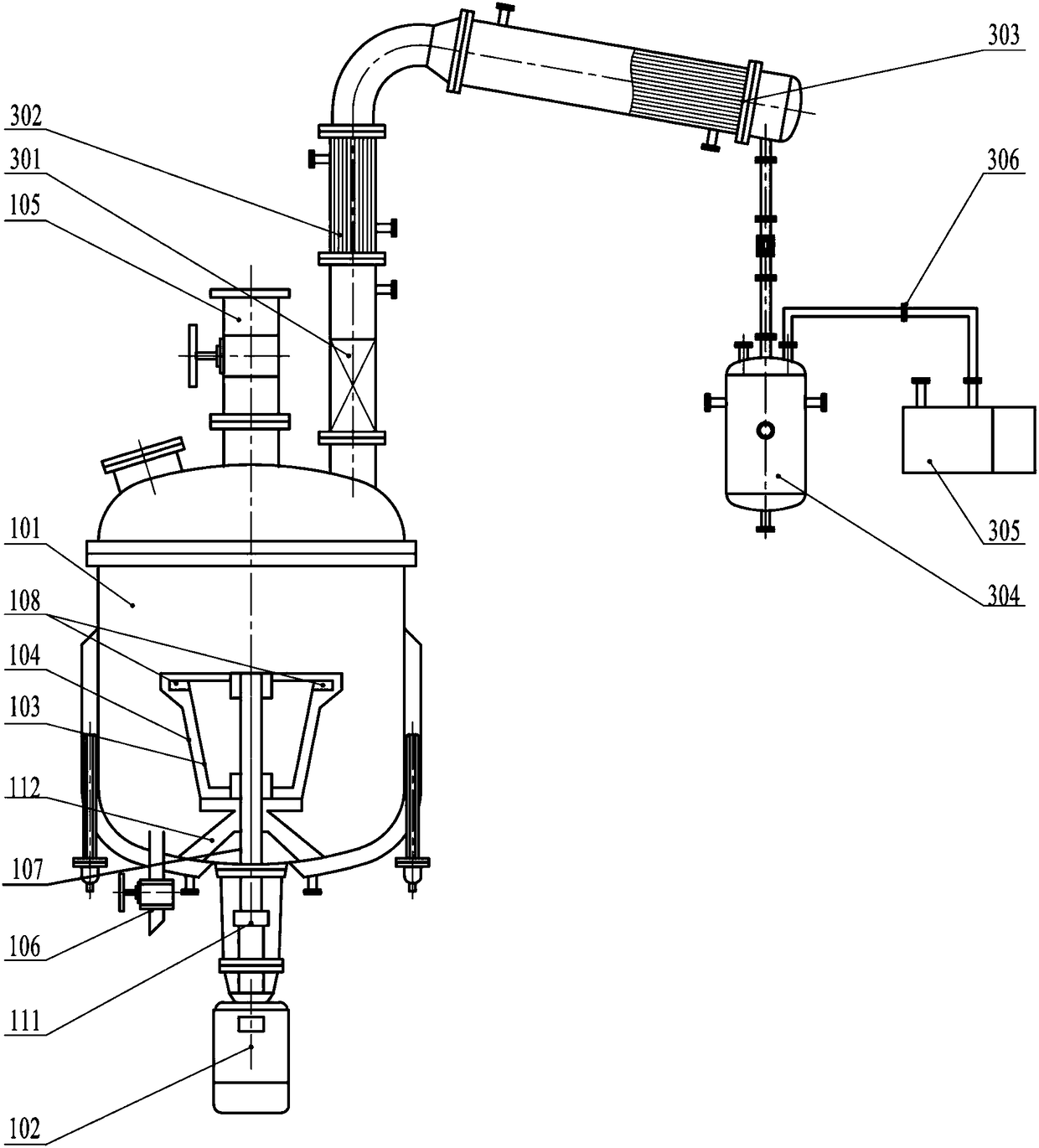

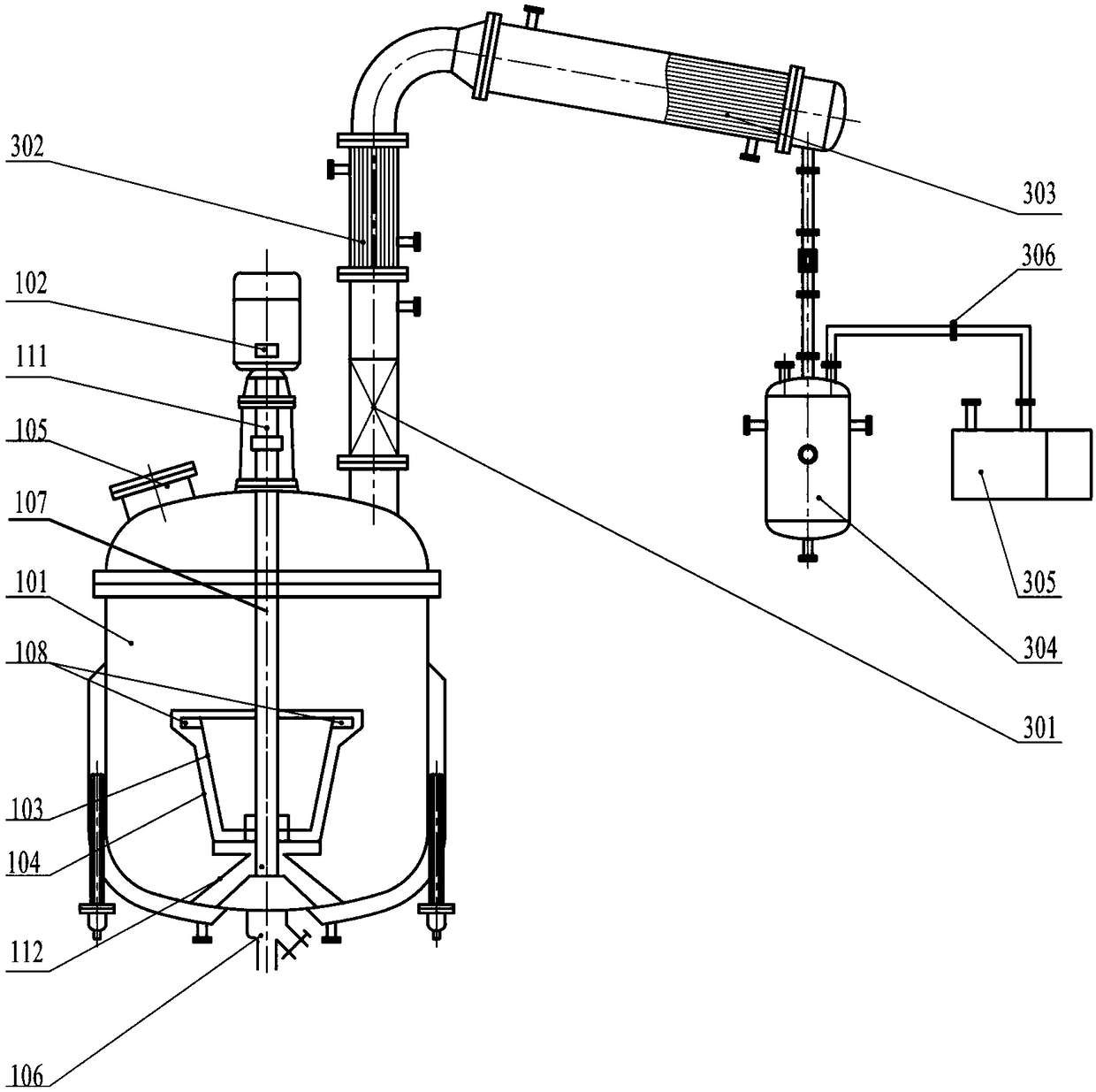

[0226] This embodiment provides a refining reaction device, including a built-in refining reaction kettle, such as Figure 2~4 As shown, the built-in refining reaction kettle includes a first kettle body 101 and a first motor 102, a fixed frame 112 is arranged in the first kettle body 101, and a first secondary grinding disc 104 is arranged on the fixed frame 112. A first main grinding disc 103 is arranged opposite to the first auxiliary grinding disc 104, and a first refining gap 123 is formed between the first main grinding disc 103 and the first auxiliary grinding disc 104, and a first feeding port is provided on the first kettle body 101 105 and the first discharge port 106, the first feed port 105 is provided with a first feed valve, the first discharge port 106 is provided with a first discharge valve, the output shaft of the first motor 102 is connected with the first main The grinding disc driving shaft 107 , the first main grinding disc driving shaft 107 drives the fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com