Electronic ink for inkjet printing and with no silver nano-wire sedimentation, and preparation method thereof

A technology of silver nanowires and inkjet printing, which is applied in inks, applications, household appliances, etc., can solve the problems of complicated process and multiple additives in conductive ink, and achieve simple process, improved adhesion performance, improved adhesion and hardness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

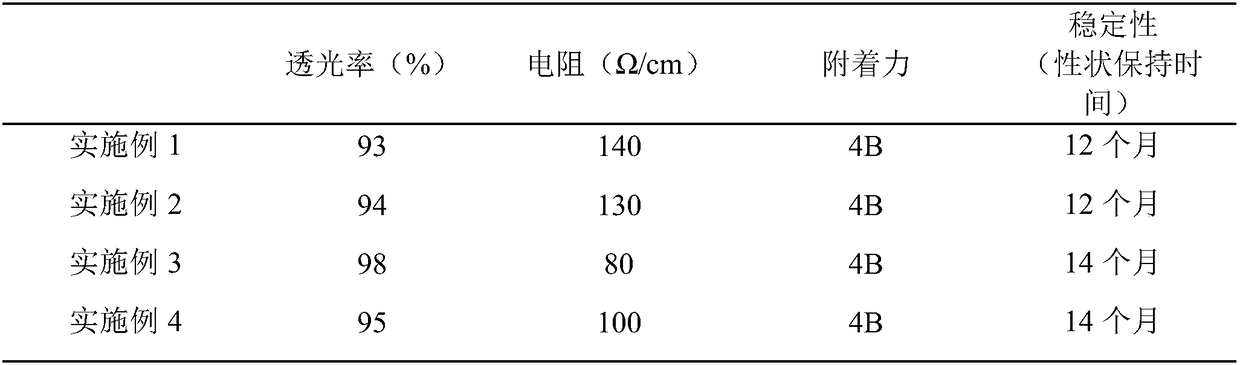

Examples

Embodiment 1

[0023] The non-settling silver nanowire inkjet printing electronic ink of the present embodiment is made up of the following components in mass fraction: 5% silver nanowire (diameter 50nm, length 5μm), 8% polyaniline, 0.2% alkane Base polyoxyethylene ether, 1% potassium dihydrogen phosphate, 85.8% deionized water.

[0024] The above materials are placed separately for later use, and the following steps are used for preparation:

[0025] 1. Take 40% deionized water and heat it to 60 degrees Celsius, pour the silver nanowires into the deionized water, and stir magnetically for 10 minutes.

[0026] 2. Ultrasonicize the solution for 10 seconds, continue to stir for 10 minutes, and repeat the steps twice to obtain solution A for later use.

[0027] 3. Add polyaniline to the remaining 45.8% deionized water, heat and stir to 80 degrees Celsius, and continue stirring for 30 minutes.

[0028] Obtain solution B for later use.

[0029] 4. Slowly add solution B into solution A under co...

Embodiment 2

[0033] The non-settling silver nanowire inkjet printing electronic ink of the present embodiment, the formula material includes 10% silver nanowire (diameter 20nm, length 20 μ m) calculated by mass fraction, 5% polythiophene, 0.3% alkane Base polyoxyethylene ether, 0.7% potassium dihydrogen phosphate, 84% deionized water.

[0034] The above materials are placed separately for later use, and the following steps are used for preparation:

[0035] 1. Take 40% deionized water and heat it to 60 degrees Celsius, pour the silver nanowires into the deionized water, and stir magnetically for 10 minutes.

[0036] 2. Ultrasonicate the solution for 10 seconds, continue to stir for 10 minutes, and repeat the steps 3 times. Obtain solution A for later use.

[0037] 3. Add polythiophene to the remaining 44% deionized water, heat and stir to 80 degrees Celsius, and continue stirring for 30 minutes to obtain solution B for later use.

[0038] 4. Slowly add solution B into solution A under c...

Embodiment 3

[0042] The non-settling silver nanowire inkjet printing electronic ink of the present embodiment, the formula material includes 6% silver nanowire (diameter 40nm, length 15 μm) calculated by mass fraction, 8% polypyrrole, 2% polypyrrole Thiophene, 0.3% alkylphenol ethoxylates, 0.5% potassium dihydrogen phosphate, 83.2% deionized water.

[0043] The above materials are placed separately for later use, and the following steps are used for preparation:

[0044] 1. Take 30% deionized water and heat it to 40 degrees Celsius, pour the silver nanowires into the deionized water, and stir magnetically for 12 minutes.

[0045] 2. Ultrasonicize the solution for 12 seconds, continue to stir for 8 minutes, and repeat the steps 2 times. Obtain solution A for later use.

[0046] 3. Add polythiophene to the remaining 44% deionized water, heat and stir to 70 degrees Celsius, and continue stirring for 40 minutes to obtain solution B for later use.

[0047] 4. Slowly add solution B into solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com