A kind of annular varistor material, its preparation method and application

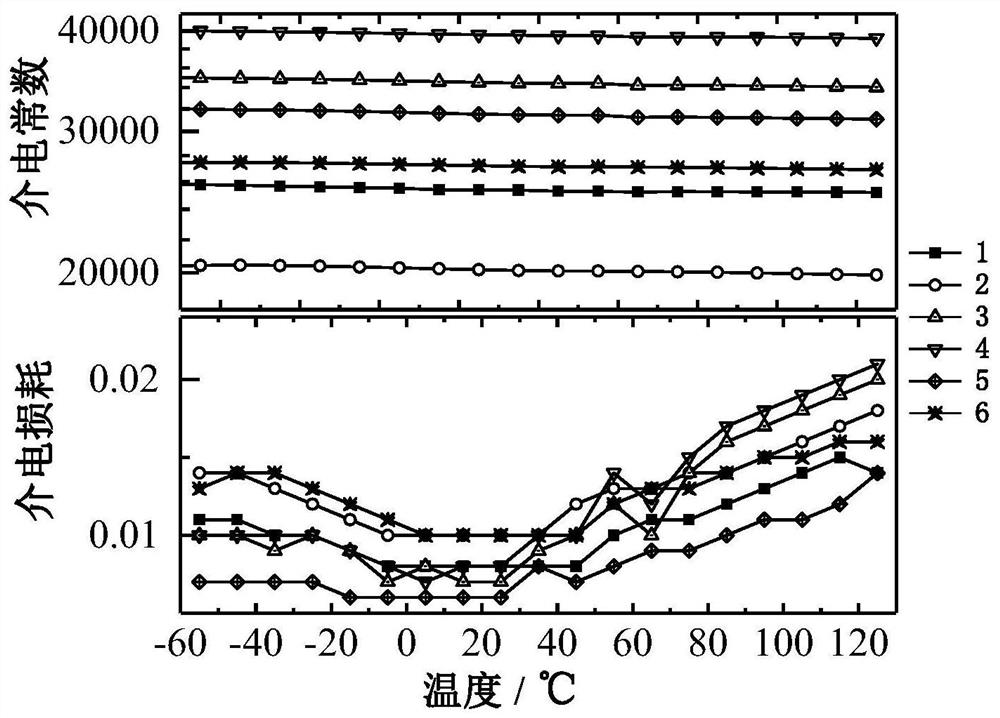

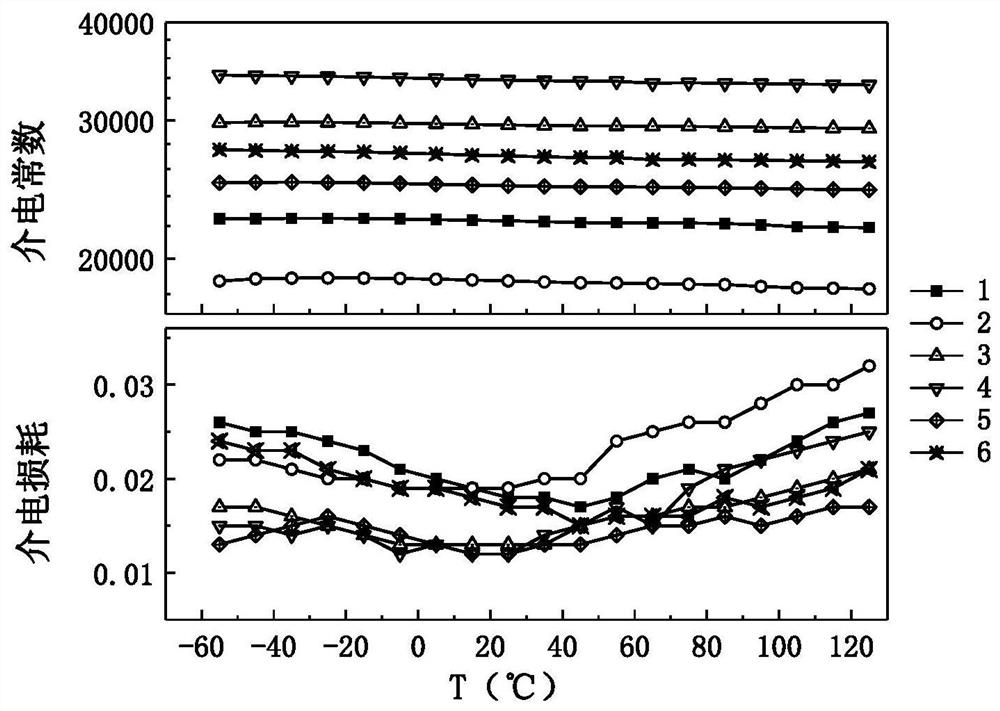

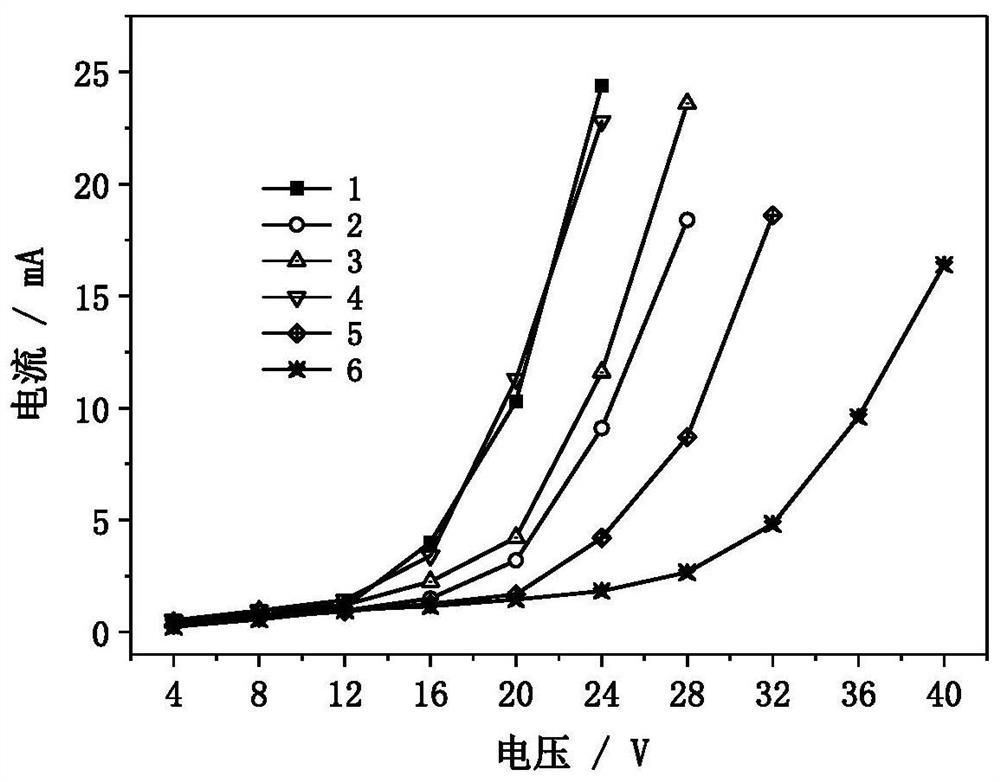

A varistor and ring-shaped technology, applied in the direction of varistors, etc., can solve the problems of large safety hazards, poor temperature stability, and difficult process parameters in the production workshop, and achieve convenient material performance, stable temperature characteristics, and large dielectric constant. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] An embodiment of the annular varistor material of the present invention, the annular varistor material described in this embodiment is prepared by the following method:

[0032] The formula of powder A is: TiO2 1mol, In 2 o 3 0.0125mol, Nb 2 o 5 0.0125mol;

[0033] The formula of powder B is: powder A 100g, SiO 2 Oxide 3.0g.

[0034] Add powder A to the polyurethane ball mill tank according to the proportion, add absolute ethanol as a solvent according to the mass ratio of 1:1.2, and add zirconium balls according to the ratio of material to ball = 1:5. After ball milling for 24 hours, the balls are separated. , dried in an oven at 75°C, treated in an air atmosphere at 1400-1470°C / 1-3h, ball milled again for 12h after treatment, and obtained powder A with a D50 of 0.5um;

[0035] The obtained powder A is ball milled or stirred for 3 hours again, and materials are doped during the process of ball milling or stirring, and SiO 2 Oxide, after ball milling and dryin...

Embodiment 2

[0038] An embodiment of the annular varistor material of the present invention, the annular varistor material described in this embodiment is prepared by the following method:

[0039] The formula of powder A is: TiO 2 1mol, Ta 2 o 3 0.0025mol, Nb 2 o 5 0.0025mol;

[0040] The formula of powder B is: powder A 100g, SiO 2 Oxide 0.5g.

[0041] Add powder A to the polyurethane ball mill tank according to the proportion, add absolute ethanol as a solvent according to the mass ratio of 1:1.2, and add zirconium balls according to the ratio of material to ball = 1:5. After ball milling for 24 hours, the balls are separated. , dried in an oven at 75°C, treated in an air atmosphere at 1400-1470°C / 1-3h, ball milled again for 12h after treatment, and obtained powder A with a D50 of 0.5um;

[0042] The obtained powder A is ball milled or stirred for 3 hours again, and materials are doped during the process of ball milling or stirring, and SiO 2 Oxide, after ball milling and dry...

Embodiment 3

[0045] An embodiment of the annular varistor material of the present invention, the annular varistor material described in this embodiment is prepared by the following method:

[0046] The formula of powder A is: TiO 2 1mol, In 2 o 3 0.025mol, Nb 2 o 5 0.025mol;

[0047] The formula of powder B is: powder A 100g, silicate 0.5g.

[0048] Add powder A to the polyurethane ball mill tank according to the proportion, add absolute ethanol as a solvent according to the mass ratio of 1:1.2, and add zirconium balls according to the ratio of material to ball = 1:5. After ball milling for 24 hours, the balls are separated. , dried in an oven at 75°C, treated in an air atmosphere at 1400-1470°C / 3h, ball milled again for 12h after treatment, and obtained powder A with a D50 of 0.5um;

[0049] The obtained powder A is again ball milled or stirred for 3 hours with pure water as the solvent, and materials are doped during the ball milling or stirring process, doped with silicate, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com