A low-damage perovskite solar cell and packaging method thereof

A solar cell and perovskite technology, applied in circuits, electrical components, photovoltaic power generation, etc., can solve the problems of perovskite solar cell damage, solar cell damage, and low barrier, so as to avoid photoelectric conversion efficiency and improve universal application performance and high encapsulation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

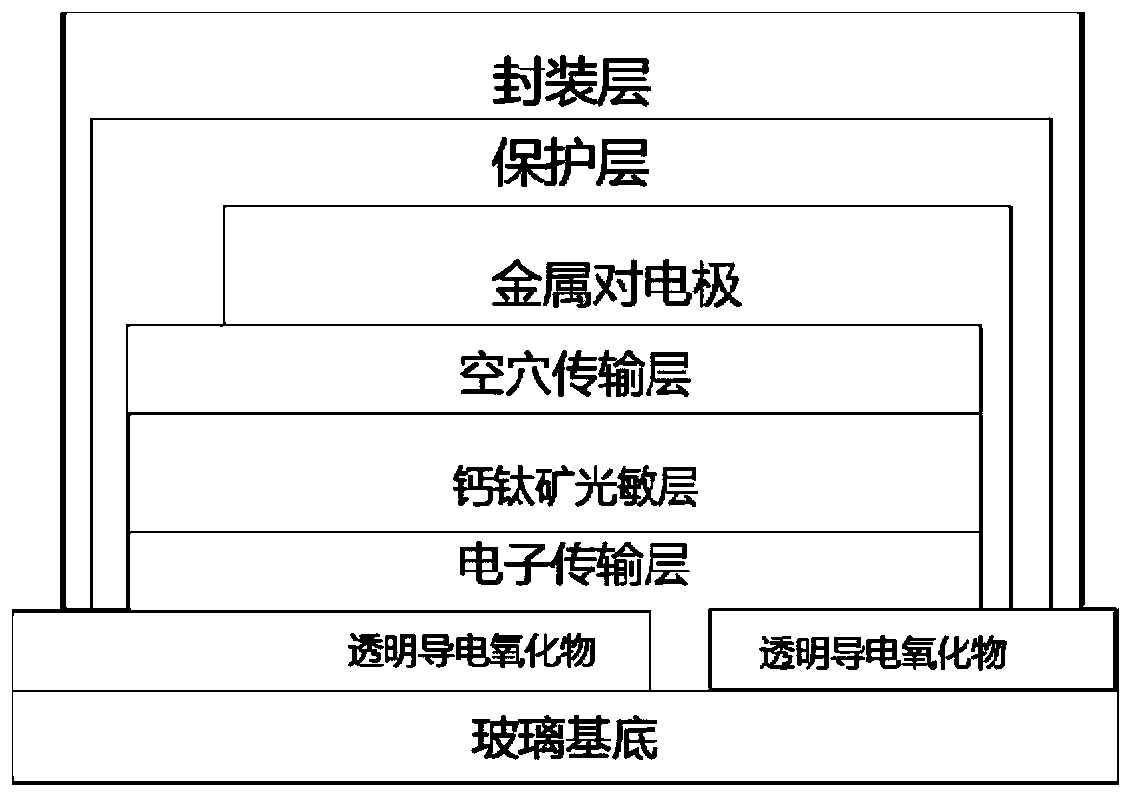

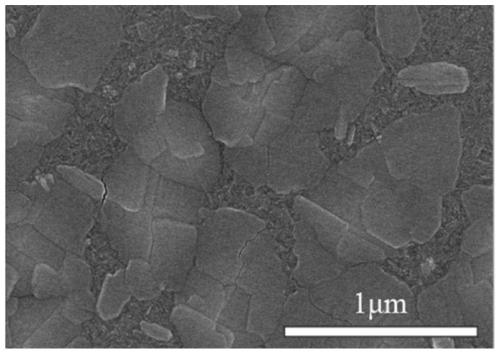

[0029] 1) Using the same process method to prepare a batch of structures as FTO / TIO 2 / MAPB 3 / Spiro-OMeTAD / Au perovskite solar cells, as far as possible to ensure that the performance of each cell is consistent, and the difference is small.

[0030] 2) Place the same batch of prepared batteries on the sample stage of the evaporation apparatus, and evaporate a layer of molybdenum oxide protective layer on the surface of the batteries, with thicknesses of 5, 10, 20, 30, 60, and 100 nm respectively, which are recorded as Example 1 -6.

[0031] 3) At AM 1.5G, 100mW / cm 2 Under simulated sunlight, the photoelectric efficiencies of cells with different thicknesses of molybdenum oxide protective layers (Examples 1-6) and without evaporation of molybdenum oxide protective layers (Comparative Example 1) were tested.

[0032] 4) Place the above battery on the magnetron sputtering sample stage, and sputter a layer of Al 2 o 3 Ceramic encapsulation material, the thickness of the enca...

Embodiment 7-10

[0040] 1) Using the same process method to prepare a batch of structures as FTO / TIO 2 / MAPB 3 / Spiro-OMeTAD / Au perovskite solar cells, as far as possible to ensure that the performance of each cell is consistent, and the difference is small.

[0041] 2) Place the same batch of prepared batteries on the sample stage of an evaporation apparatus, and evaporate a protective layer of molybdenum oxide on the surface of the batteries with a thickness of 60 nm.

[0042] 3) Move the above battery to the magnetron sputtering sample stage, and sputter aluminum oxide with a thickness of 100nm, 300nm, 500nm, and 700nm (respectively referred to as Examples 7-10).

[0043] 4) At AM 1.5G, 100mW / cm 2 Under simulated sunlight, the initial photoelectric efficiencies of the cells of Examples 7-10 were tested and normalized. The batteries of Examples 7-10 and Comparative Example 2 were placed together in an environmental chamber for a stability test. The test conditions were a temperature of 30...

Embodiment 11

[0046] 1) Using the same process method to prepare a batch of structures as FTO / TIO 2 / MAPB 3 / Spiro-OMeTAD / Au perovskite solar cells, as far as possible to ensure that the performance of each cell is consistent, and the difference is small.

[0047] 2) Place the same batch of prepared batteries on the sample stage of an evaporation apparatus, and evaporate a protective layer of molybdenum oxide on the surface of the batteries with a thickness of 60 nm.

[0048] 3) Place the above battery on the magnetron sputtering sample stage, and sputter a layer of SiN X Ceramic encapsulation material, the thickness of the encapsulation layer is 500nm.

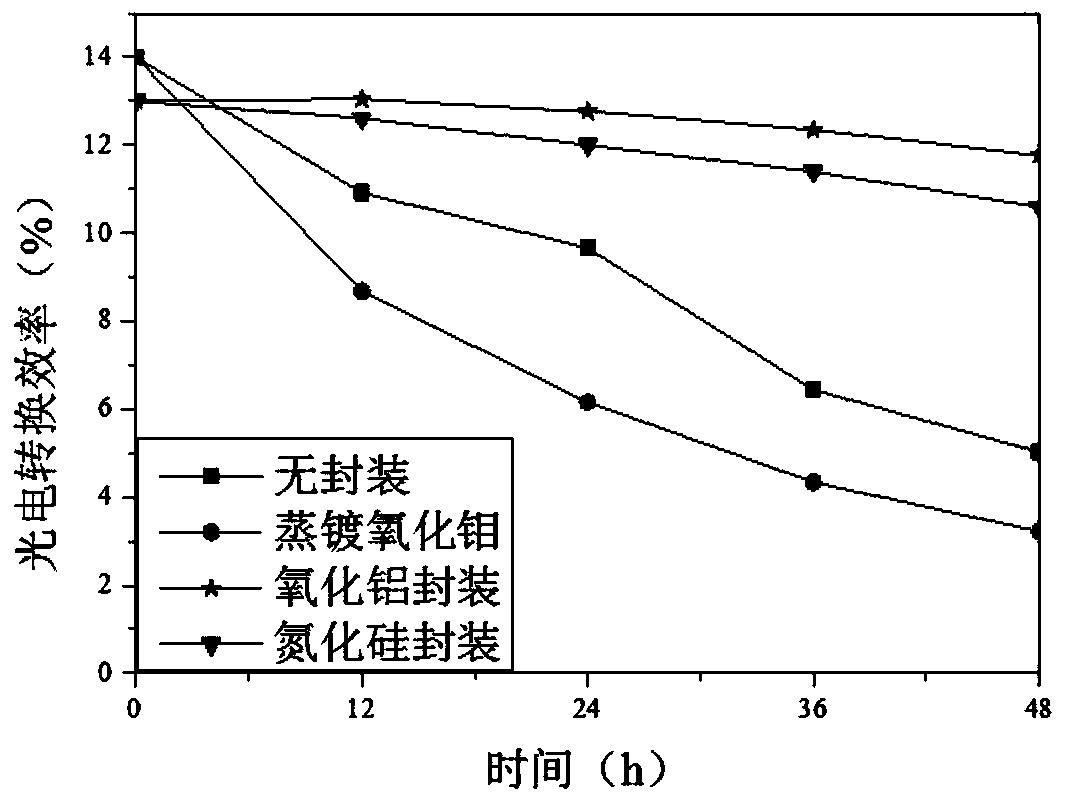

[0049] 4) The packaged battery is placed in an environmental chamber for a stability test, and the test conditions are 30° C., 30% humidity, and no light. Then at AM 1.5G, 100mW / cm 2 Under the simulated sunlight, the photoelectric efficiency of the above-mentioned battery is tested over time, and the results are as follows: figure 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com