Preparation method of chitosanase

A technology of chitosanase and chitosan, applied in the direction of microorganism-based methods, biochemical equipment and methods, glycosylation enzymes, etc., can solve the high production cost of chitosan oligosaccharides, enzyme production and enzyme activity Low, difficult to meet the needs of chitosan oligosaccharide production, etc., to achieve the effect of simple separation and purification steps, great application potential, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

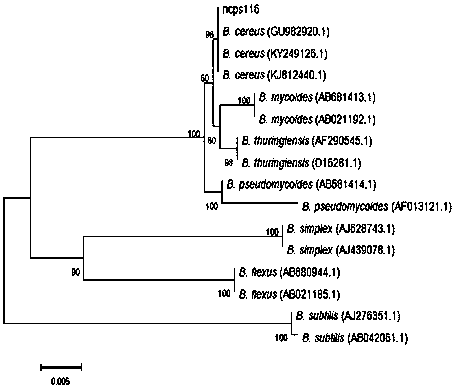

[0037] The Bacillus cereus (Bacillus cereus) 116 is preserved in the China Center for Type Culture Collection, address: Wuhan, China, Wuhan University, postcode: 430072, the preservation number is: CCTCC NO: M2017803, and the preservation date is December 2017 18th.

[0038] After the strain 116 was cultured on the slant medium for 72 hours, the colonies were off-white, dull, opaque, with irregular edges, round or nearly round, and the diameter of the colonies was about 2 to 4 mm (the attached figure figure 1 ); Gram staining of the bacterial strain was positive (instructions accompanying drawing figure 2 ), the thalline is rod-shaped, with blunt ends, producing spores, and the spores are born in the middle or side of the thalline.

[0039] The results of physiological and biochemical experiments of strain 116 are shown in Table 1, the strain 10% NaCl growth experiment, mannitol, sorbitol utilization experiment, indole experiment and H 2 The results of the S test were negat...

Embodiment 2

[0046] Strain culture

[0047] (1) Slant culture: inoculate the preserved Bacillus cereus 116 strain on the test tube slant medium, and cultivate at 30-32°C for 2-3d; the slant medium (w / v): 0.5% ammonium sulfate, phosphoric acid Dipotassium Hydrogen 0.2%, Sodium Chloride 0.5%, Magnesium Sulfate 0.1%, Powdered Chitosan 1.0%, Agar 2.0%, pH 6-7;

[0048] (2) Seed activation: the Bacillus cereus 116 bacterial strain preserved on the slant was inoculated in the seed medium, cultivated at 30-32° C. for 24 hours at 150 rpm to obtain an activated seed solution; the seed medium (w / v ): peptone 0.5%, powdered chitosan 0.5%, glucose 0.1%, sodium chloride 0.5%, dipotassium hydrogen phosphate 0.07%, potassium dihydrogen phosphate 0.03%, yeast powder 0.3%, magnesium sulfate 0.05%, pH 6- 7;

[0049] (3) Enzyme production by fermentation: insert the activated seed liquid into the enzyme production medium for fermentation, and cultivate for 60-72h at 30-32°C and 150rpm; the enzyme productio...

Embodiment 3

[0052] Optimization of fermentation enzyme production conditions

[0053] The relative enzyme activity calculation method used: the measured sample enzyme activity in each group: the maximum sample enzyme activity × 100% in each group.

[0054] (1) Effect of carbon source on enzyme production of strains

[0055] Carbon source is the raw material for building microbial cells and synthesizing various metabolites, and is also the main source of energy for microorganisms. Colloidal chitosan, soluble starch, dextran, maltose, sucrose, and lactose were used to replace the powdered chitosan in the fermented enzyme production medium respectively, and the influence of carbon source on the fermented enzyme produced was investigated. The results are shown in the accompanying drawings Figure 4 As shown, powdered chitosan is most conducive to the fermentation of this strain to produce enzymes

[0056] (2) Effect of nitrogen source on enzyme production of strains

[0057] Nitrogen sourc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Michaelis constant | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com