A kind of cathodic electrophoretic paint and its preparation method and application

A cathodic electrophoretic coating and raw material technology, applied in the coating field, can solve the problems of great environmental hazard, difficult to biodegrade, unable to meet the new requirements of high-end hardware products, etc., and achieve the effect of being friendly to the environment and the human body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

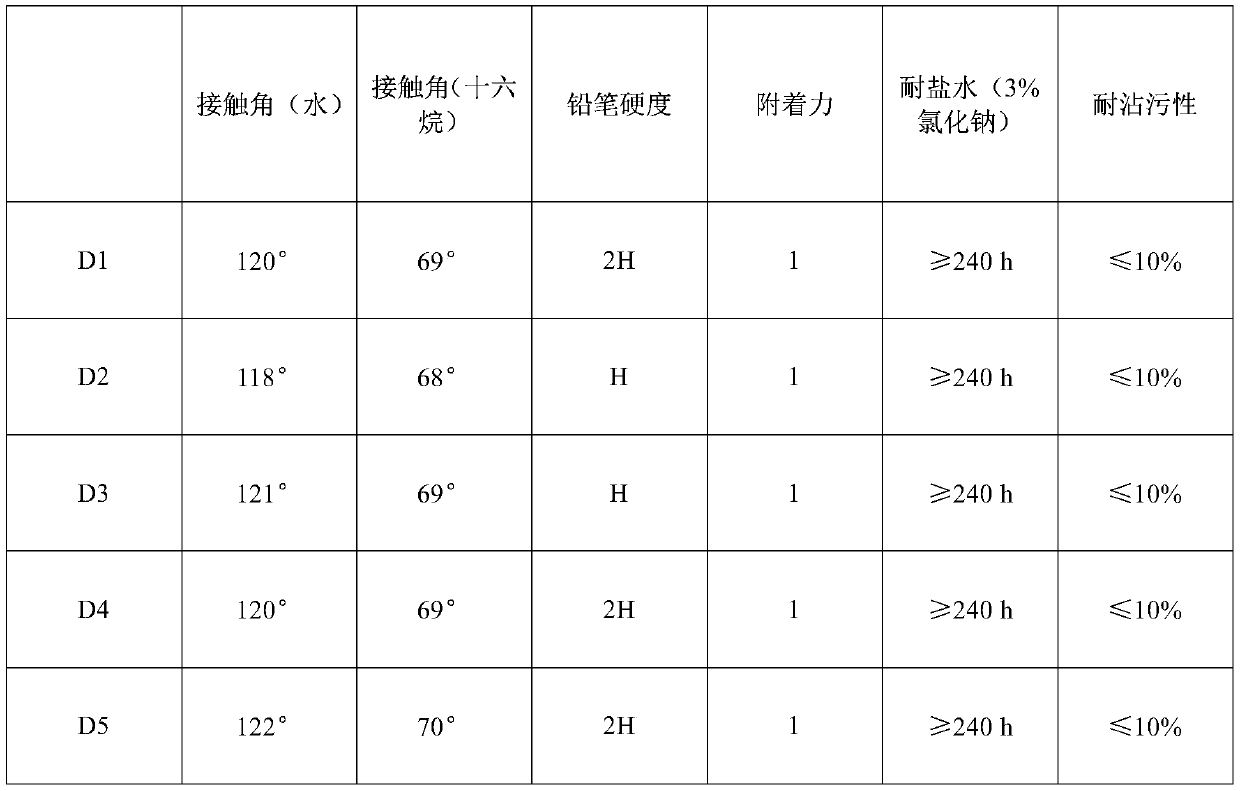

Examples

Embodiment 1

[0056] The preparation of embodiment 1 cationic perfluoropolyether modified resin

[0057] In a reaction vessel equipped with a thermometer, reflux condenser, stirrer, and nitrogen protection, add 70.00g of A1, 20.00g of tert-butyl (meth)acrylate, 10.00g of glycidyl methacrylate, 100.00g of ethylene glycol mono Dimethyl ether and 0.50g of azobisisobutyronitrile were heated to control the reaction temperature at 65°C, and reacted for 12 hours, then added 8.00g of ethylenediamine, kept the temperature for 3 hours, and finally added 16.50g of acetic acid, and stirred for 60 minutes to obtain The cationic perfluoropolyether modified resin B1.

Embodiment 2

[0058] Preparation of embodiment 2 cationic perfluoropolyether modified resin

[0059] In a reaction vessel equipped with a thermometer, reflux condenser, stirrer, and nitrogen protection, add 50.00g of A2, 45.00g of octadecyl (meth)acrylate, 5.00g of glycidyl methacrylate, 100.00g of ethylene glycol Alcohol monoethyl ether and 0.50 g of azobisisobutyronitrile. Heat to control the reaction temperature at 65°C, react for 12 hours, then add 4.00g of ethylenediamine, keep it warm for 3 hours, and finally add 8.50g of acetic acid and stir for 60 minutes to prepare the cationic perfluoropolyether modified resin B2.

Embodiment 3

[0060] Embodiment 3 Preparation of Cationic Perfluoropolyether Modified Resin

[0061] In a reaction vessel equipped with a thermometer, reflux condenser, stirrer, and nitrogen protection, add 60.00g of A3, 35.00g of hexadecyl (meth)acrylate, 5.00g of glycidyl acrylate, 100.00g of ethylene glycol mono Ethyl ether and 0.50g of azobisisobutyronitrile were heated to control the reaction temperature at 65°C and reacted for 12 hours, then 4.00g of ethylenediamine was added and kept for 3 hours, and finally 10.00g of formic acid was added and stirred for 60 minutes to obtain a cationic perfluoropolymer. Ether modified resin B3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com