Solid wood composite baking varnish door with pvc instead of primer process and its preparation process

A technology of solid wood compounding and preparation technology, which is applied in the direction of wood layered products, door leaves, manufacturing tools, etc., can solve the problems of low production efficiency and complicated process, and achieve the effects of low production cost, increased affinity and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

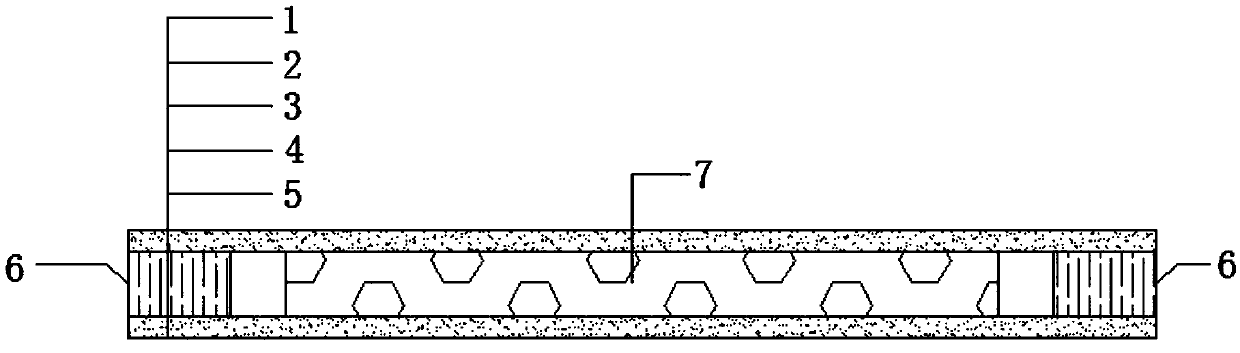

[0028] A solid wood composite baking varnish door with PVC instead of primer process, including a door leaf, the door leaf is made of panels on the upper surface and lower surface, profile materials on the side and fillers on the inside, which are combined by cold pressing, wherein:

[0029] The panel includes a medium-fiber board and a facing material on the surface of the medium-fiber board;

[0030] The finishing material comprises a PVC film and paint coated on the surface of the PVC film;

[0031] There is an edge band on the outside of the side of the door leaf.

[0032] Wherein, the retaining material is poplar LVL, and the retaining material is located on both sides or four sides of the door leaf, and the filling material is a bridge hole mechanical plate.

[0033] Wherein, the thickness of the PVC film is 0.1 mm, and the thickness of the paint is 0.02 mm.

[0034] Wherein, the sealing edge adopts PVC sealing tape edge, and the thickness of the PVC sealing tape edge ...

Embodiment 2

[0036] A solid wood composite baking varnish door with PVC instead of primer process, including a door leaf, the door leaf is made of panels on the upper surface and lower surface, profile materials on the side and fillers on the inside, which are combined by cold pressing, wherein:

[0037] The panel includes a medium-fiber board and a facing material on the surface of the medium-fiber board;

[0038] The finishing material comprises a PVC film and paint coated on the surface of the PVC film;

[0039] There is an edge band on the outside of the side of the door leaf.

[0040] Wherein, the retaining material is poplar LVL, and the retaining material is located on both sides or four sides of the door leaf, and the filling material is a bridge hole mechanical plate.

[0041] Wherein, the thickness of the PVC film is 0.15mm, and the thickness of the paint is 0.05mm.

[0042] Wherein, the sealing edge adopts PVC sealing tape edge, and the thickness of the PVC sealing tape edge i...

Embodiment 3

[0044] A solid wood composite baking varnish door with PVC instead of primer process, including a door leaf, the door leaf is made of panels on the upper surface and lower surface, profile materials on the side and fillers on the inside, which are combined by cold pressing, wherein:

[0045] The panel includes a medium-fiber board and a facing material on the surface of the medium-fiber board;

[0046] The finishing material comprises a PVC film and paint coated on the surface of the PVC film;

[0047] There is an edge band on the outside of the side of the door leaf.

[0048] Wherein, the retaining material is poplar LVL, and the retaining material is located on both sides or four sides of the door leaf, and the filling material is a bridge hole mechanical plate.

[0049] Wherein, the thickness of the PVC film is 0.12mm, and the thickness of the paint is 0.05mm.

[0050] Wherein, the sealing edge adopts PVC sealing tape edge, and the thickness of the PVC sealing tape edge i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com