Bacterial cellulose reinforced high elastic modulus mortar for prefabricated buildings and preparation method thereof

A technology for bacterial cellulose and construction, which is applied in the field of bacterial cellulose-enhanced high-elastic mold mortar for prefabricated construction and its preparation, can solve problems such as immaturity in technology and management, and achieve increased cohesion and flow. properties, and the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

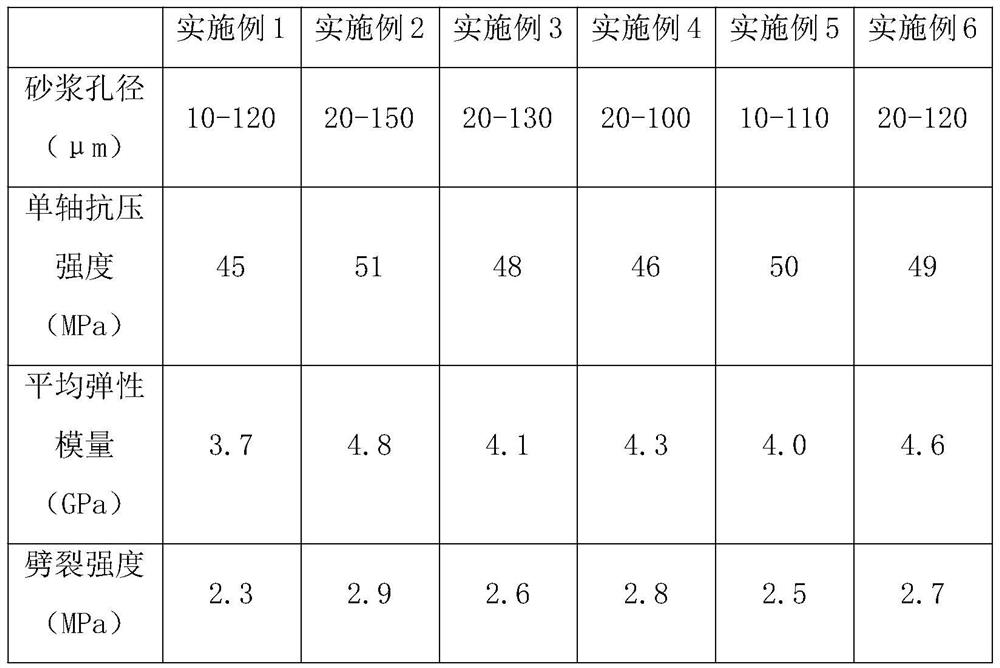

Examples

Embodiment 1

[0024] (1) Grind the dried bacterial cellulose to 50-100 μm, then add it to the aqueous acetic acid solution, add sodium carboxymethyl cellulose, and disperse it by ultrasonic at 20 kHz for 20 minutes until uniform, to obtain a bacterial cellulose suspension, wherein the bacterial cellulose The content of sodium carboxymethyl cellulose in the cellulose suspension is 0.6%, and the content of bacterial cellulose is 12%.

[0025] (2) Add triterpene saponin or alkyl sulfonate into the solvent and mix evenly, then add 0.1-1mm porous metal oxide, 5-20mm porous molecular sieve and 30-40mm porous regenerative building with a mass ratio of 1:3:1 Particles, wherein the pore size of the porous particle material is 80-300 μm, after slowly stirring at a speed of 50r / min for 1-2h, adding an epoxy resin polymer, stirring evenly at a speed of 5000r / min for 5min, and obtaining adsorption attraction The particle packing solution of the air-entraining agent, wherein the content of the air-entrai...

Embodiment 2

[0028] (1) Grind the dried bacterial cellulose to 50-100 μm, then add it to the aqueous acetic acid solution, add sodium carboxymethyl cellulose, and disperse it by ultrasonic at 30 kHz for 30 minutes until it is uniform to obtain a bacterial cellulose suspension, wherein the bacterial cellulose The content of sodium carboxymethyl cellulose in the cellulose suspension is 0.75%, and the content of bacterial cellulose is 18%.

[0029] (2) Add triterpene saponin or alkyl sulfonate into the solvent and mix evenly, then add 0.1-1mm porous metal oxide, 5-20mm porous molecular sieve and 30-40mm porous regenerative building with a mass ratio of 1:5:2 Particles, wherein the porous particle material has a pore size of 80-300 μm, after slowly stirring at a speed of 100r / min for 2h, adding epoxy resin polymer, stirring evenly at a speed of 12000r / min for 20min, and obtaining an adsorption air-entraining agent The particle filler solution, wherein, the content of the air-entraining agent i...

Embodiment 3

[0032](1) Grind the dried bacterial cellulose to 50-100 μm, then add it to the aqueous acetic acid solution, add sodium carboxymethyl cellulose, and disperse ultrasonically for 25 minutes at a power of 25 kHz until uniform to obtain a bacterial cellulose suspension, wherein the bacterial cellulose The content of sodium carboxymethyl cellulose in the cellulose suspension is 0.65%, and the content of bacterial cellulose is 15%.

[0033] (2) Add triterpene saponin or alkyl sulfonate into the solvent and mix evenly, then add 0.1-1mm porous molecular sieve, 5-20mm porous regenerative building particles and 30-40mm porous regenerative building with a mass ratio of 1:4:1.5 Particles, wherein the pore size of the porous granular material is 80-300 μm, after slowly stirring at a speed of 80r / min for 1.5h, adding epoxy resin polymer, stirring evenly at a speed of 8000r / min for 10min, to obtain adsorption air The particle filler solution of the agent, wherein, the content of the air-entr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com