Machining method for eliminating needle plate deformation

A processing method and needle plate technology, which is applied in the field of formwork processing, can solve the problems of limited plate thickness, large deformation size, thermal change of the plate, etc., and achieve the effects of avoiding arching, high balance and verticality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with embodiment the present invention is further described in detail. It should be pointed out that the following specific descriptions are all exemplary, and are intended to provide further description of the present invention. Unless otherwise specified, all scientific and technical terms used in this invention have the same meaning as commonly understood by those skilled in the art to which this invention belongs.

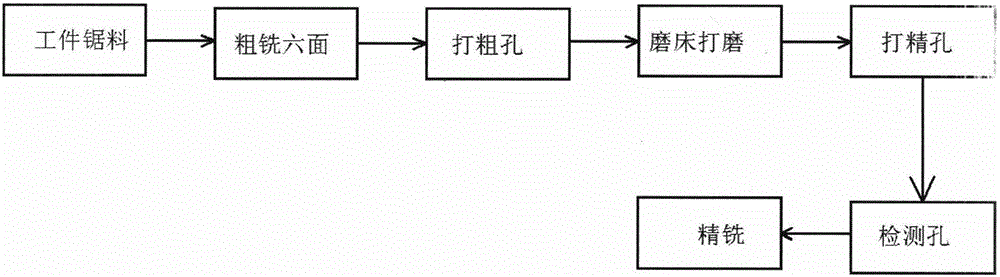

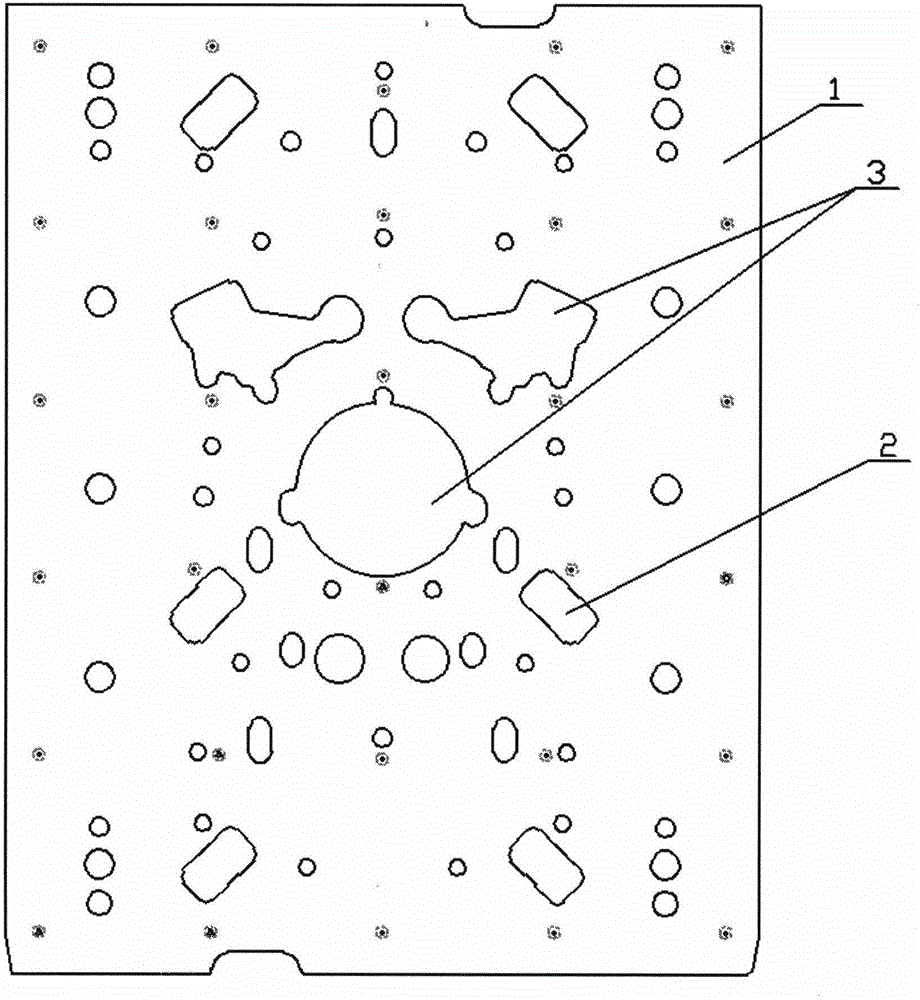

[0019] as attached figure 1 As shown, a processing method for eliminating the deformation of the needle plate, the method includes: sawing the workpiece, rough milling six sides, grinding with a grinder, drilling rough holes, drilling fine holes, detecting holes, and fine milling;

[0020] The workpiece sawing material is based on the size of the drawing and the machining allowance of each process is reserved. The specific machining allowance is 8-12mm more than the thickness of the finished product. Use a sawing machine to cut out a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com