Copper ammonia fiber fabric and preparation method thereof

A technology of cupro fiber and fabric, applied in the field of fabric textiles, can solve the problems of strong moisture absorption, poor resistance of cupro fiber, poor alkali resistance of cupro fiber, etc., and achieve the effect of good mechanical properties, excellent moisture absorption and quick drying performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

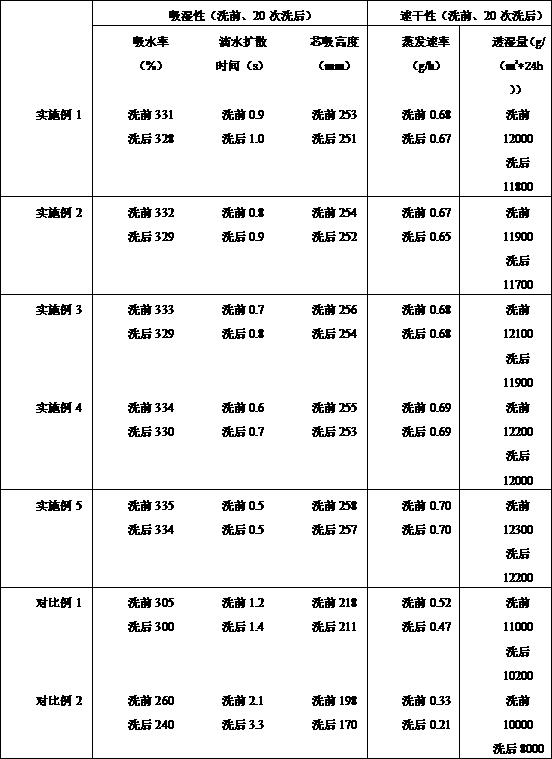

Examples

Embodiment 1

[0045] A kind of preparation method of copper ammonia fiber fabric, concrete steps are as follows:

[0046] (1) Firstly, the modified cupro ammonia fiber is made from cotton linter natural cellulose, concentrated ammonia solution of copper compound, and γ-aminopropyltriethoxysilane modified nano-alumina;

[0047] (2) Then the mass ratio of 1:0.2:0.03 modified cupro ammonia fiber, methacryloxypropyltrimethoxysilane modified ultrafine nylon fiber and water-soluble vinylon fiber network to form mixed filament I;

[0048] (3) Next, the modified cupro ammonia fiber with a mass ratio of 1:0.1 and the superfine polyester fiber network are formed into mixed filament II;

[0049] (4) Finally, use a loom to weave the mixed filament I and the mixed filament II into warp and weft yarns respectively to obtain a fabric blank, and vacuum heating and finishing removes the water-soluble vinylon fiber to obtain the cupro ammonia fiber fabric;

[0050] Among them, the specific method of vacuum ...

Embodiment 2

[0066] A kind of preparation method of copper ammonia fiber fabric, concrete steps are as follows:

[0067] (1) Firstly, the modified cupro ammonia fiber is made from cotton linter natural cellulose, concentrated ammonia solution of copper compound, and γ-aminopropyltriethoxysilane modified nano-alumina;

[0068] (2) The mass ratio 1: 0.3: 0.04 modified cupro ammonia fiber, methacryloxypropyltrimethoxysilane modified ultrafine nylon fiber and water-soluble vinylon fiber network to form mixed filament I;

[0069] (3) Next, the modified cupro ammonia fiber with a mass ratio of 1:0.2 and the superfine polyester fiber network are formed into mixed filament II;

[0070] (4) Finally, use a loom to weave the mixed filament I and the mixed filament II into warp and weft yarns respectively to obtain a fabric blank, and vacuum heating and finishing removes the water-soluble vinylon fiber to obtain the cupro ammonia fiber fabric;

[0071] Among them, the specific method of vacuum heatin...

Embodiment 3

[0087] A kind of preparation method of copper ammonia fiber fabric, concrete steps are as follows:

[0088] (1) Firstly, the modified cupro ammonia fiber is made from cotton linter natural cellulose, concentrated ammonia solution of copper compound, and γ-aminopropyltriethoxysilane modified nano-alumina;

[0089] (2) Then the mass ratio of 1:0.2:0.04 modified cupro ammonia fiber, methacryloxypropyltrimethoxysilane modified ultrafine nylon fiber and water-soluble vinylon fiber network to form mixed filament I;

[0090] (3) Next, the modified cupro ammonia fiber with a mass ratio of 1:0.1 and the superfine polyester fiber network are formed into mixed filament II;

[0091](4) Finally, use a loom to weave the mixed filament I and the mixed filament II into warp and weft yarns respectively to obtain a fabric blank, and vacuum heating and finishing removes the water-soluble vinylon fiber to obtain the cupro ammonia fiber fabric;

[0092] Among them, the specific method of vacuum h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com