Mixed active agent for activing flux tungsten inert gas arc welding of magnesium alloy

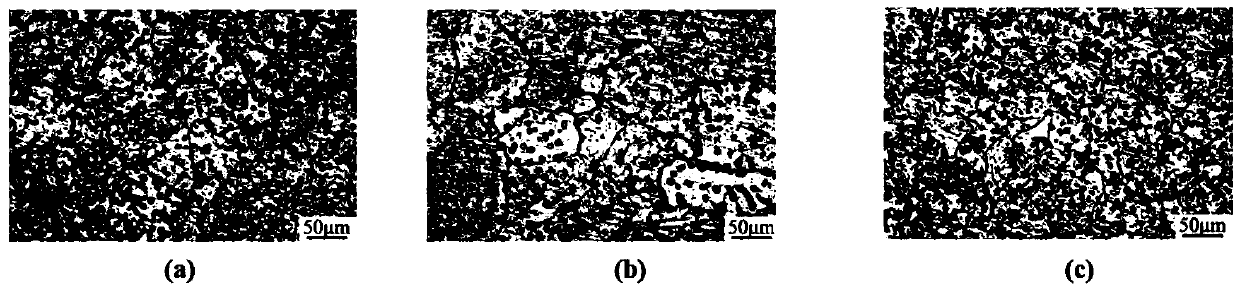

A technology of argon tungsten arc welding and activator, which is applied in arc welding equipment, welding equipment, welding medium, etc., can solve the problems of increasing melting depth, grain coarsening, adverse effects on the structure and performance of welded joints, etc. The effect of weld penetration and weld grain refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] AZ31 magnesium alloy single pass TIG butt welding welding process:

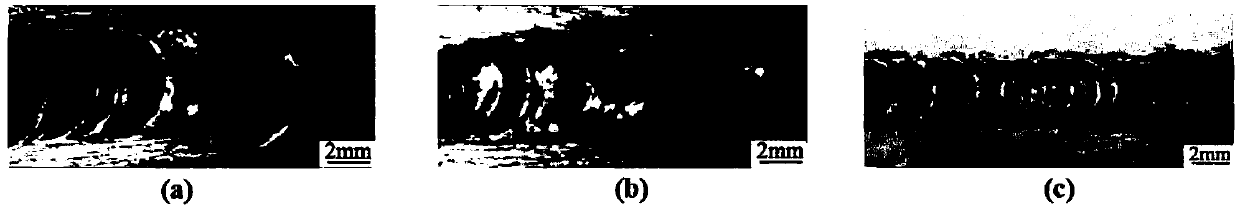

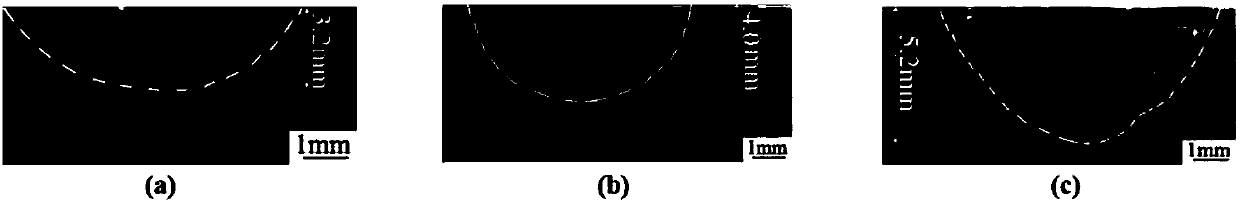

[0019] The experiment adopts AC TIG welding machine (NSA-500-1) to carry out TIG welding on AZ31 magnesium alloy. In the experiment, no active agent was applied, and a single MnCl 2 Active agent and MnCl 2 The active agent was mixed with ZnO for comparative experiments.

[0020] Active agent weight ratio is MnCl 2 : 70% and ZnO: 30%. MnCl 2 and ZnO active agent powder are fully ground and mixed in proportion, and then acetone is added to the mixture to make it into a paste. while single MnCl 2 The active agent is directly adjusted into a paste with acetone. Then use a flat brush to evenly coat the pasty active agent on the upper surface of the sample, the coating width is about 40mm, and the average coating amount of the active agent is 6mg·cm -2 . Solder after the acetone evaporates.

[0021] The specific welding process parameters are as follows:

[0022] The welding specifications adopted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com