SnBiAgSbIn low-temperature lead-free solder alloy

A lead-free solder alloy, low temperature technology, used in welding/cutting media/materials, welding media, welding equipment, etc. The effect of reducing surface tension and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

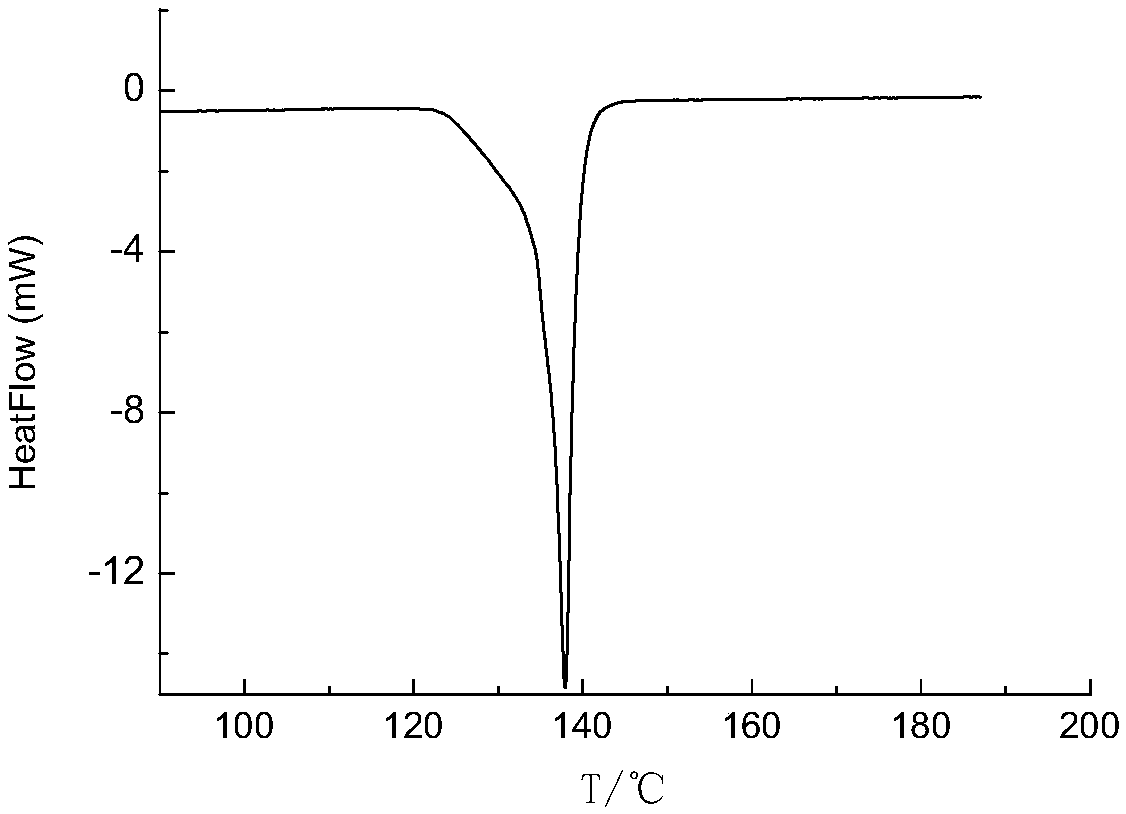

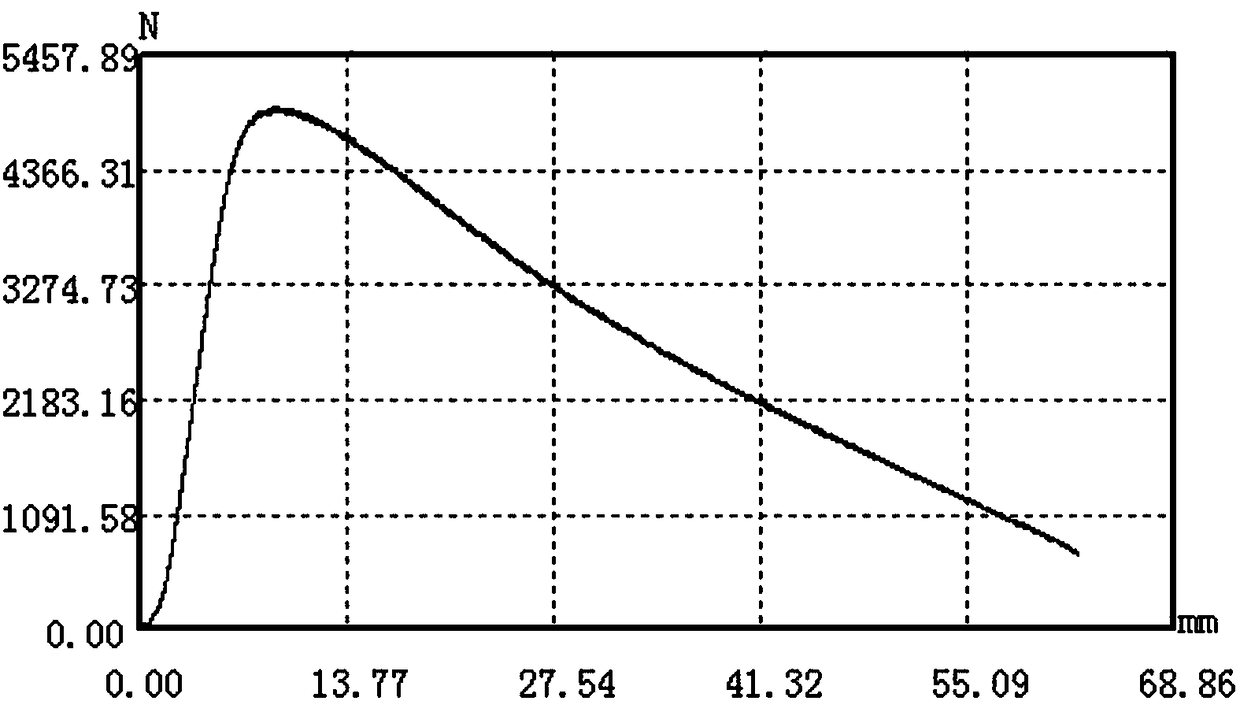

Image

Examples

Embodiment Construction

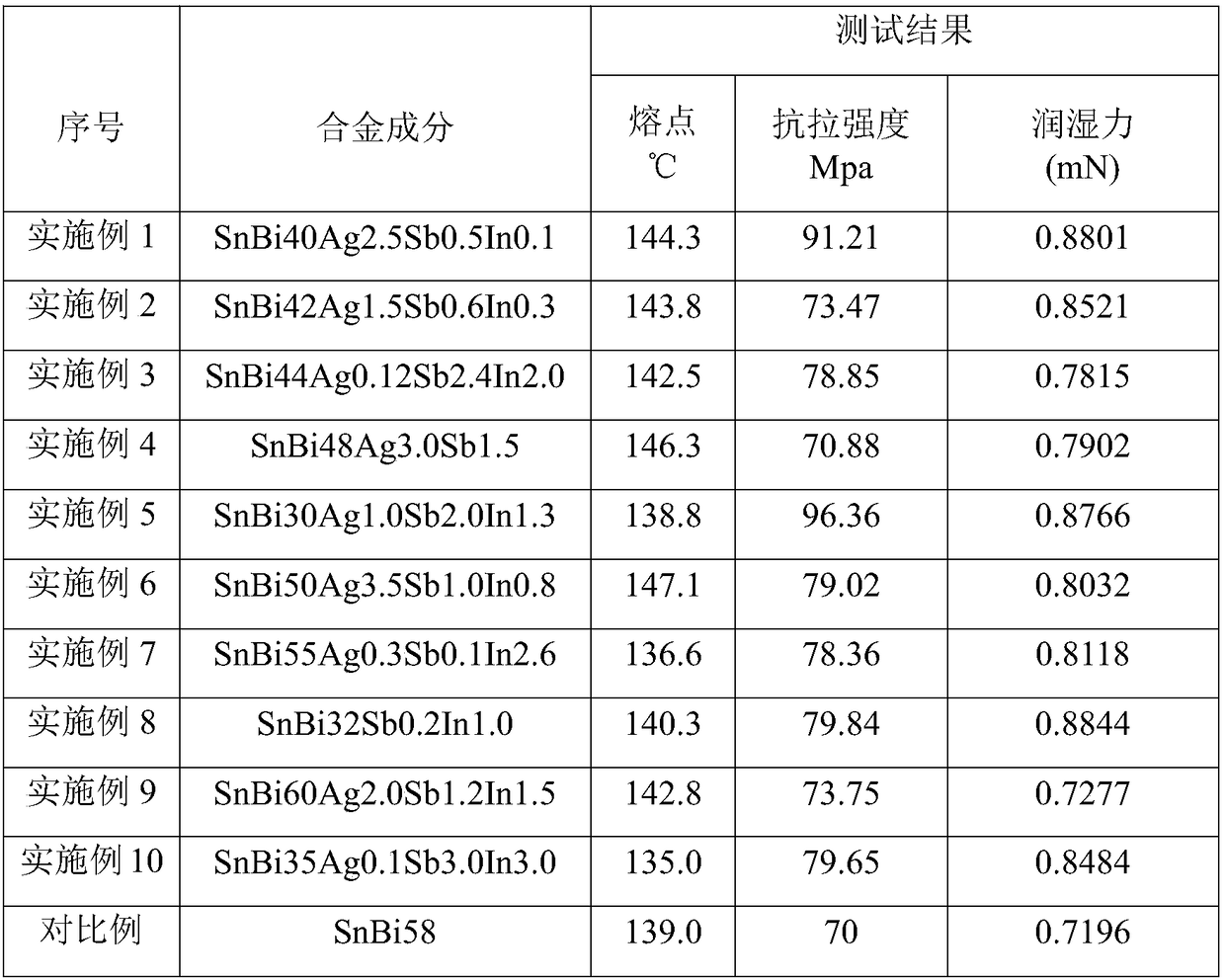

[0033] The present invention will be described in further detail below in conjunction with specific embodiments, but the protection scope of the present invention is not limited to the content described.

[0034] The alloy formulations of specific examples and comparative examples of the present invention are shown in Table 1 (in mass percent), wherein the comparative example is a comparison of the properties of the SnBi58 eutectic solder alloy with the examples.

[0035] Table 1 embodiment and comparative example

[0036] alloy

Bi

Ag

In

Sb

Ge

P

Y

La

Ce

Pr

scope

30-60

0-3.5

0-3.0

0.1-3

0-0.11

0-0.11

0-0.5

0-0.5

0-0.5

0-0.5

Example 1

40

2.5

0.1

0.5

0.08

0.002

0.01

0.01

0

0.1

Example 2

42

1.5

0.3

0.6

0.04

0.01

0

0.02

0.03

0

Example 3

44

0.12

2.0

2.4

0.06

0.02

0.25

0

0

0.01

Example 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com