Wear-resisting and corrosion-resisting coating for boiler pipe wall and preparation method thereof

A corrosion-resistant coating, boiler tube technology, applied in the direction of coating, metal material coating process, melt spraying, etc., to prevent grain growth, simplify the process flow, and refine the coating structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The powder used for spraying contains nano-CeO 2 Powder weight percentage is 0%; Cr 3 C 2 -NiCr powder weight percent is 100%.

[0034]The substrate used for spraying is T91 special steel, and the surface of the substrate is degreased, derusted and sandblasted before spraying. Preheat the substrate to 120°C, preheat the powder to 100°C, and then spray with active combustion high-velocity gas spray (AC-HVAF). The main spraying process parameters are: spraying distance 320mm, gas chamber 1 pressure 97psi, gas chamber 2 Pressure is 102psi, air pressure is 108psi, N 2 The air flow rate is 70L / min, the powder feeding rate is 72g / min, the spraying angle is 90°, and the number of spraying times is 6 times; the thickness of the sprayed coating is 200μm.

Embodiment 2

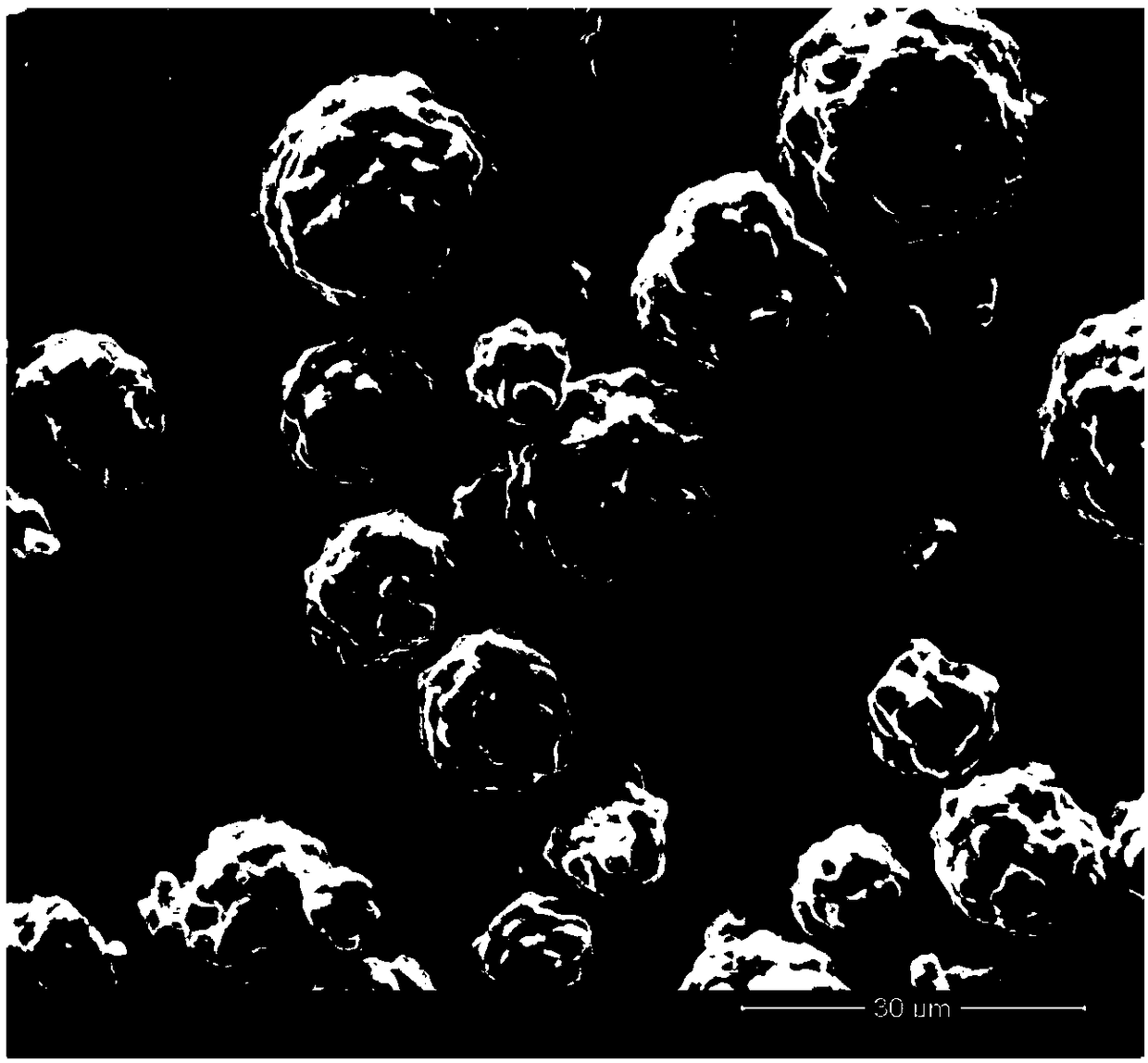

[0036] Use mechanical mixing powder, the powder includes CeO with a particle size of 10-35nm 2 Powder and Cr with a particle size of 15-45 μm 3 C 2 -NiCr powder two components. Nano CeO in powder 2 Powder weight percentage is 10%; Cr 3 C 2 -NiCr powder weight percent is the balance. During preparation, put the two powders into a ball mill, set the speed at 200r / min, and mix for 8 hours, and use them after uniform mixing. After mixing, the particle size of the obtained mixed powder is between 25 and 35 μm, and the shape is spherical, CeO 2 Particles attached to Cr 3 C 2 -NiCr particle surface.

[0037] The substrate used for spraying is T91 special steel, and the surface of the substrate is degreased, derusted and sandblasted before spraying. Preheat the substrate to 110°C, preheat the powder to 110°C, and then use active combustion high-velocity gas spraying (AC-HVAF) for spraying. The main spraying process parameters are: fuel type is propane, fuel I pressure is 97P...

Embodiment 3

[0039] Use mechanical mixing powder, the powder includes CeO with a particle size of 10-35nm 2 Powder and Cr with a particle size of 15-45 μm 3 C 2 -NiCr powder two components. CeO in powder 2 Powder weight percentage is 20%; Cr 3 C 2 -NiCr powder weight percent is the balance. During preparation, put the two powders into a ball mill, set the speed at 200r / min, and mix for 8 hours, and use them after uniform mixing. After mixing, the particle size of the obtained mixed powder is between 25 and 35 μm, and the shape is spherical, CeO 2 Particles attached to Cr 3 C 2 -NiCr particle surface.

[0040] The substrate used for spraying is T91 special steel, and the surface of the substrate is degreased, derusted and sandblasted before spraying. Preheat the substrate to 100°C, preheat the powder to 130°C, and then use active combustion high-velocity gas spraying (AC-HVAF) for spraying. The main spraying process parameters are: fuel type is propane, fuel I pressure is 100Psi, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com