A kind of laser cladding Fe-based Cr3C2 composite coating adding nanometer Ti and preparation method thereof

A technology of laser cladding and composite coating, applied in the direction of coating, metal material coating process, etc., can solve the problems of high brittleness of the coating, poor compatibility of the substrate, easy to produce cracks, etc. Good toughness, the effect of promoting melting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

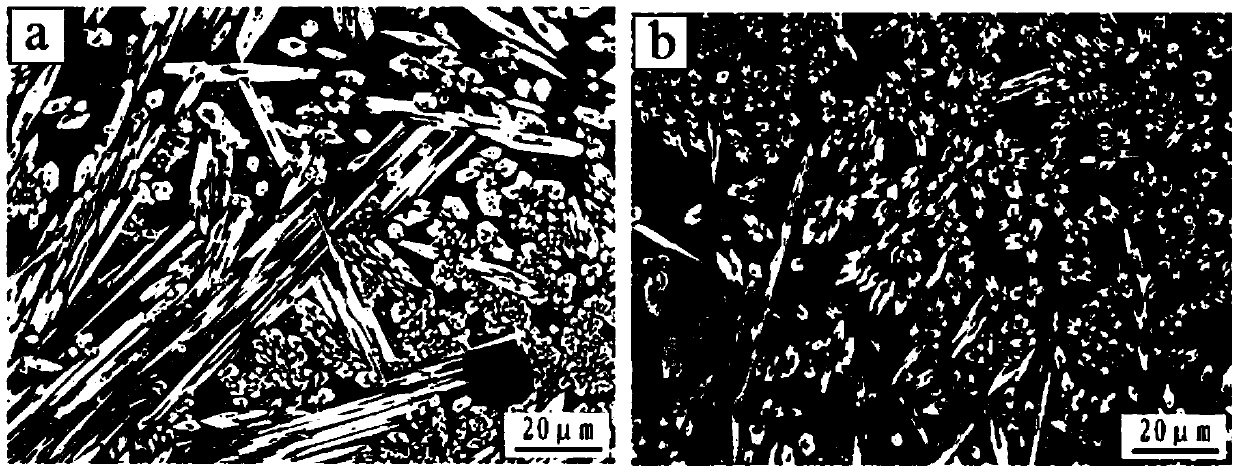

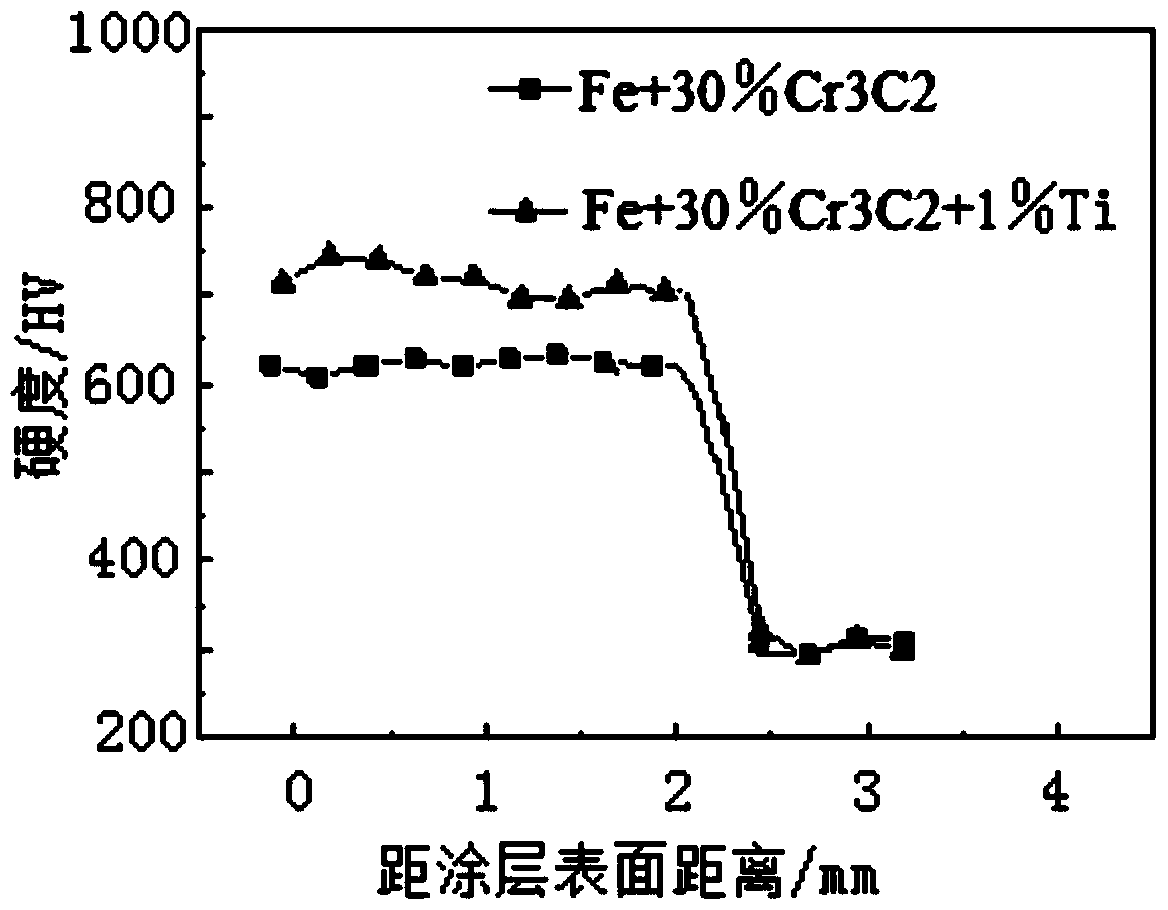

Embodiment 1

[0045] A laser cladding Fe-based Cr with nano-Ti added in this embodiment 3 C 2 The composite coating is prepared by laser cladding with the following mass percentage components: 69% iron-based self-fluxing alloy powder, nano-Cr 3 C 2 30% alloy powder and 1% nano-Ti powder, wherein the Fe-based self-fluxing alloy powder consists of the following components by mass percentage: C0.1%, Cr16%, Ni8%, Si2.5%, B1.2%, Mo0.5%, Fe is the balance, and its particle size is about 65 μm. In this embodiment, nano-Cr is added to the cladding powder 3 C 2 , due to nano-Cr 3 C 2 It is easier to be melted during the plasma surfacing process, therefore, when Cr 3 C 2 When the addition amount is the same, the nano-Cr 3 C 2 Cr in powder 3 C 2 The amount of melting is more than micron Cr 3 C 2 , while nano-Cr 3 C 2 The powder contains more particles and the distribution is more dispersed, which increases the number of non-spontaneous nucleation cores and significantly refines the coa...

Embodiment 2

[0076] A laser cladding Fe-based Cr with nano-Ti added in this embodiment 3 C 2 The composite coating is prepared by laser cladding with the following mass percentage components: 59% iron-based self-fluxing alloy powder, nano-Cr 3 C 2 40% alloy powder and 1% nano-Ti powder, wherein the Fe-based self-fluxing alloy powder consists of the following components by mass percentage: C0.2%, Cr18%, Ni7%, Si2.0%, B0.8%, Mo is 0.6%, Fe is the balance, and its particle size is 100 μm. In this embodiment, nano-Cr is added to the cladding powder 3 C 2 , due to nano-Cr 3 C 2 It is easier to be melted during the plasma surfacing process, therefore, when Cr 3 C 2 When the addition amount is the same, the nano-Cr 3 C 2 Cr in powder 3 C 2 The amount of melting is more than micron Cr 3 C 2 , while nano-Cr 3 C 2 The powder contains more particles and the distribution is more dispersed, which increases the number of non-spontaneous nucleation cores and significantly refines the coat...

Embodiment 3

[0088] A laser cladding Fe-based Cr with nano-Ti added in this embodiment 3 C 2 The composite coating is prepared by laser cladding with the following mass percentage components: 71% iron-based self-fluxing alloy powder, nano-Cr 3 C 2 28.5% alloy powder and 0.5% nano-Ti powder, wherein the Fe-based self-fluxing alloy powder is composed of the following components in mass percentage: C0.15%, Cr15%, Ni6.5%, Si2.3%, B1.0 %, Mo0.6%, Fe is the balance, and its particle size is 180 μm. In this embodiment, nano-Cr is added to the cladding powder 3 C 2 , due to nano-Cr 3 C 2It is easier to be melted during the plasma surfacing process, therefore, when Cr 3 C 2 When the addition amount is the same, the nano-Cr 3 C 2 Cr in powder 3 C 2 The amount of melting is more than micron Cr 3 C 2 , while nano-Cr 3 C 2 The powder contains more particles and the distribution is more dispersed, which increases the number of non-spontaneous nucleation cores and significantly refines th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com