Porous carbon material based on two-dimensional polymer and preparation and application thereof

A technology of porous carbon materials and polymers, applied in the preparation/purification of carbon, carbon compounds, other chemical processes, etc., can solve the problems of not significantly improving the carbon dioxide adsorption capacity of the material, increasing the specific surface area, and poor adsorption capacity, etc. Achieve the effects of low production cost, simple synthesis process and convenient method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] (1) Synthesis of pyrene-based two-dimensional polymers

[0045] Accurately weigh pyrene (1.5g, 7.4mmol) and aluminum trichloride (5.92g, 44.4mmol) into a 100mL double-necked round-bottomed flask, pass nitrogen gas for 15min, and then add 30mL CHCl 3, stirred at room temperature for 15 min, then raised the reaction temperature to 58° C., and reacted for 3 days. In addition, the molar ratio of pyrene to aluminum trichloride (in the range of 1:3-1:8) can be changed to prepare pyrene-based two-dimensional polymers with different specific surface areas. The product is post-treated, and the specific method is as follows: add the product to a 3mol / L KOH solution, stir at room temperature, and wait until the massive solid is completely dispersed, use a Buchner funnel for suction filtration, use a large amount of ethanol during the suction filtration process, and deionize Washed with water, then dried at 70°C, the dried product was subjected to Soxhlet extraction with ethanol a...

Embodiment 2

[0054] (1) Synthesis of naphthyl two-dimensional polymers

[0055] Naphthalene (1.28g, 10mmol) and dimethoxymethane (2.6-5.2ml, 30-60mmol) were dissolved in 20ml of 1,2-dichloroethane, and anhydrous ferric chloride (4.86-9.72g, 30- 60mmol), stirred evenly at room temperature. Then the temperature was raised to 25-80°C and stirred for 24-36h. After the reaction is completed, filter and post-process the product. The specific method is as follows: add the product to a 3mol / L hydrochloric acid solution, stir at room temperature, and wait until the massive solids are completely dispersed, then use a Buchner funnel to carry out suction filtration. A large amount of water and methanol, deionized water are washed, and the product adopts anhydrous methanol to carry out Soxhlet extraction, and the time is 3 days, and the productive rate is more than 95% (wt), carries out EDS elemental analysis to the product finally obtained, and iron ion content is lower than 5wt%. In this embodimen...

Embodiment 3

[0061] According to the method of Example 2 step (1) to prepare phenyl two-dimensional polymer, the difference is that naphthalene is replaced by equimolar benzene, and the product structural formula is as follows:

[0062] m and n represent the number of repeating units, and the specific surface area of the product is 800-1200m 2 / g.

[0063] Then, the phenyl porous carbon material was prepared according to the method of step (2) of Example 1, except that sodium chloride was selected as the pore-forming agent, and the carbonization temperature was 600°C.

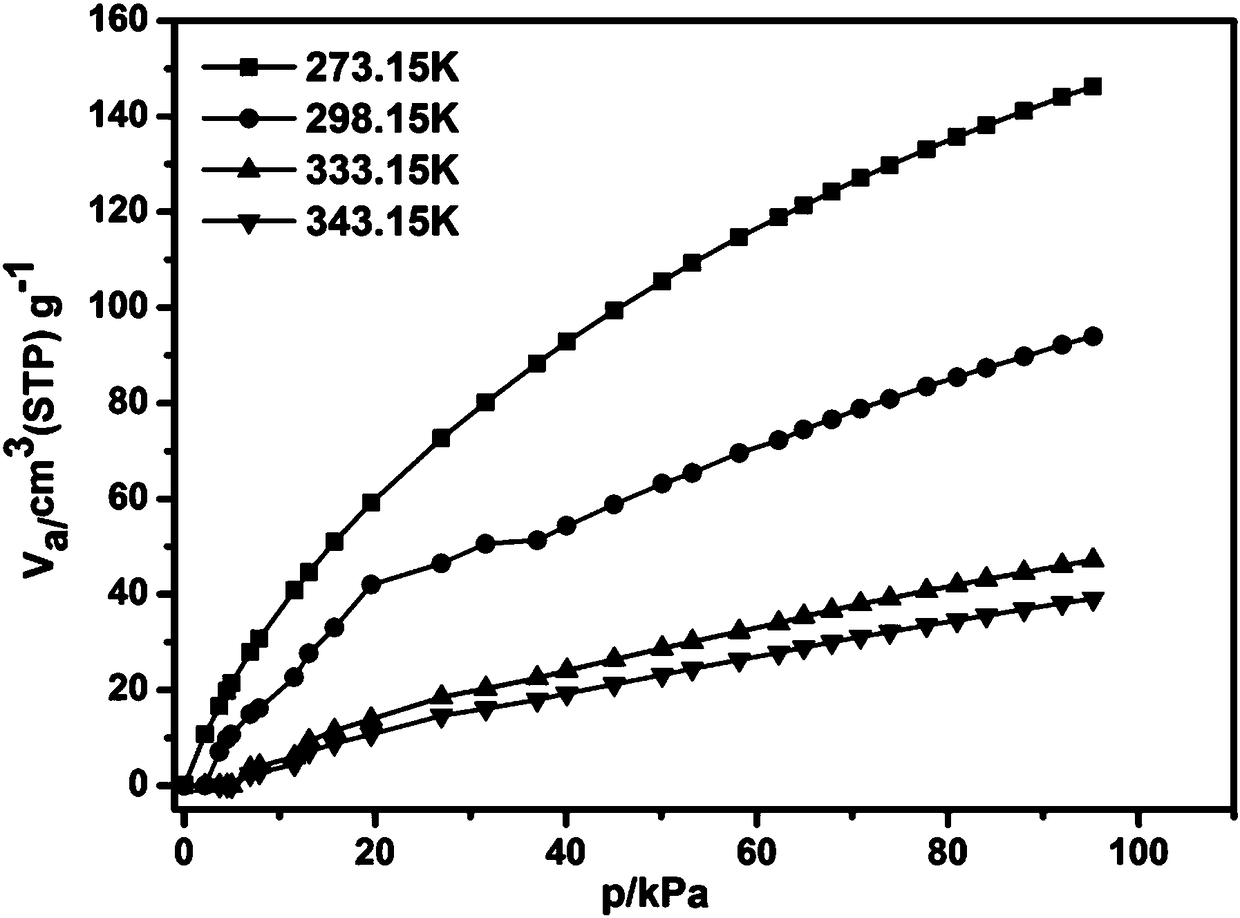

[0064] The phenyl porous carbon material prepared in this example can also absorb CO at 0-90°C 2 , CO 2 The pressure is 0.015-0.1MPa, at 60-90℃ for CO 2 Still have good adsorption capacity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com