Composite oxide coating and its preparation method and application

A composite oxide and coating technology, which is applied in textiles, papermaking, fiber treatment, etc., can solve the problems of easy cracks and peeling of coatings, achieve the effects of not easy to fall off, easy to obtain, and improve high temperature oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Preparation of solution A: slowly add 0.7 g of lanthanum acetate powder into 8 g of deionized water, and then magnetically stir at room temperature for 30 minutes to completely dissolve the lanthanum acetate, and the solution becomes clear and transparent to obtain solution A. Preparation of solution B: slowly add 8 g of glacial acetic acid and 0.7 g of zirconium n-butoxide into 8 g of ethanol successively, and magnetically stir for 30 min at room temperature to fully mix the solution evenly to obtain solution B. Under the condition of magnetic stirring, slowly add the A solution to the B solution at a rate of 2ml / min until the A solution is added dropwise, and continue stirring for 10 minutes at room temperature to fully hydrolyze the zirconium-butoxide to obtain a stable and transparent zirconium-lanthanum composite oxide biosol.

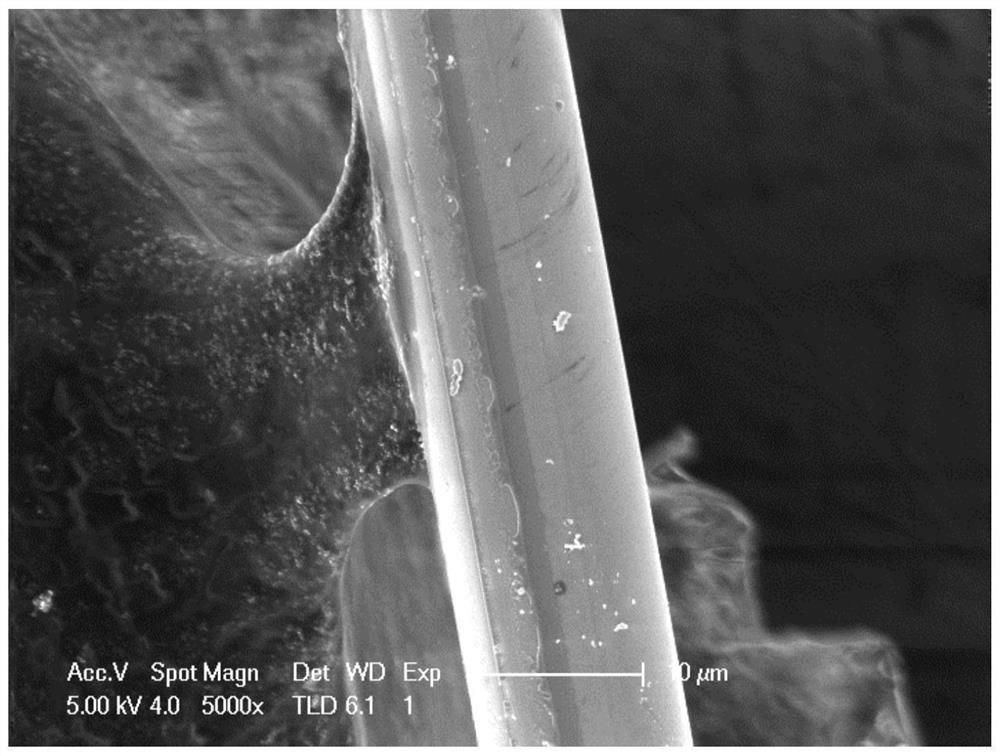

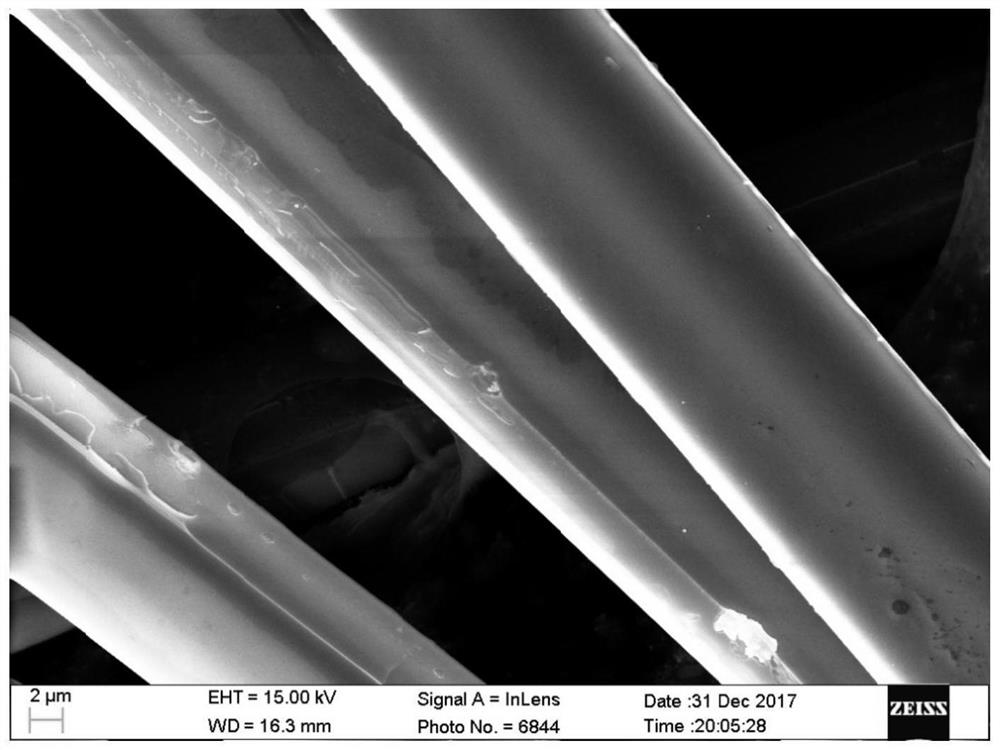

[0038] Soak the silicon carbide fiber in the above-mentioned zirconium-lanthanum composite oxide sol and ultrasonically vibrate for 20 min...

Embodiment 2

[0041]Preparation of solution A: slowly add 0.5 g of lanthanum acetate powder into 8 g of water, stir magnetically at room temperature for 30 minutes after the addition, to completely dissolve the lanthanum acetate, and the solution becomes clear and transparent to obtain solution A. Preparation of solution B: slowly add 8 g of glacial acetic acid and 0.5 g of zirconium n-butoxide into 8 g of ethanol successively, and magnetically stir for 30 min at room temperature to fully mix the solution evenly to obtain solution B. Under the condition of magnetic stirring, slowly add solution A to solution B at a rate of 1ml / min until solution A is added dropwise, and continue to stir for 10 minutes at room temperature to fully hydrolyze zirconium-butoxide to obtain a stable and transparent zirconium-lanthanum composite oxide sol.

[0042] Soak the silicon carbide fiber in the above-mentioned zirconium-lanthanum composite oxide sol and ultrasonically vibrate for 20 minutes, then take it o...

Embodiment 3

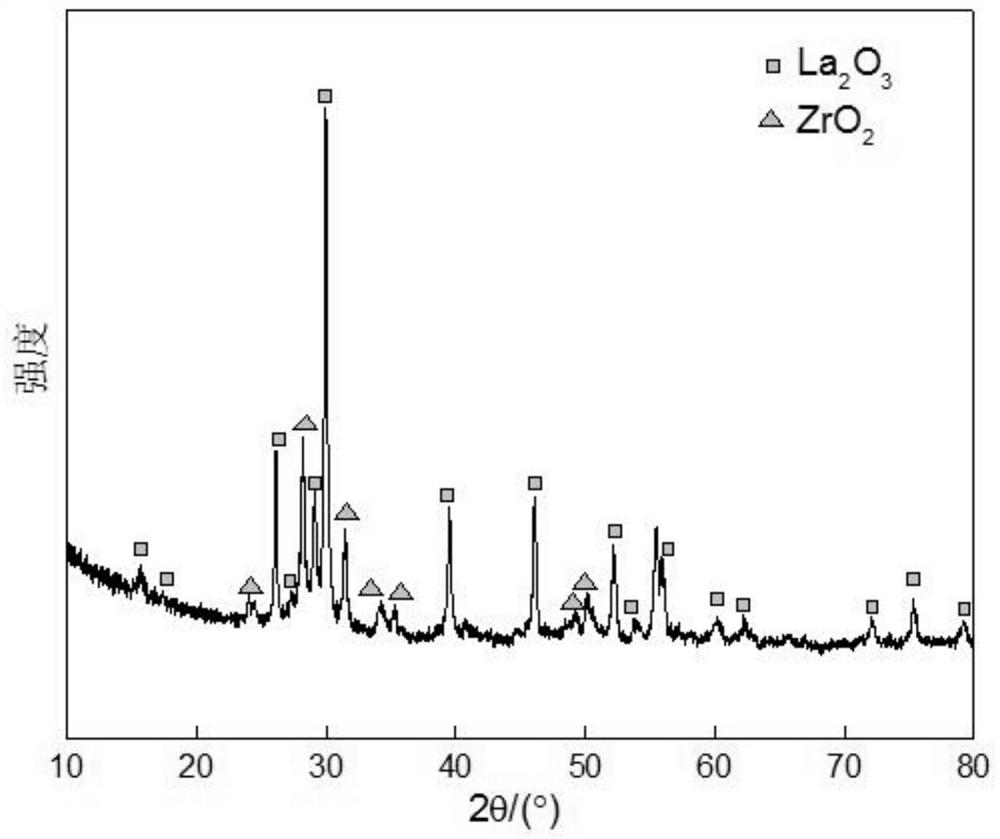

[0044] Prepare four parts of A solution: take 4 parts of 8g deionized water each, slowly add 0.3g, 0.5g, 0.7g and 0.9g of lanthanum acetate powder into 8g of deionized water, and stir magnetically at room temperature for 30min after the addition is completed, so that Lanthanum acetate was completely dissolved, and the solution became clear and transparent.

[0045] Prepare four parts of solution B: take 4 parts of the mixed solution of 8g ethanol and 8g glacial acetic acid, add 0.3g, 0.5g, 0.7g, and 0.9g of zirconium n-butoxide into the mixed solution of 8g ethanol and 8g glacial acetic acid respectively, at room temperature Under magnetic stirring for 30min, the solution is fully mixed evenly; take the A and B solutions corresponding to lanthanum acetate and zirconium n-butoxide with the same quality, and slowly add the A solution to the B solution at a speed of 5ml / min under magnetic stirring conditions. Continue to stir for 10 min at room temperature until the addition of s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com