Anti-corrosion treating fluid for aluminum alloy and application method of anti-corrosion treating fluid

An aluminum alloy, corrosion-resistant technology, applied in the field of treatment liquid, can solve the problems of poor corrosion resistance of film formation, etc., and achieve the effects of improving corrosion resistance, improving processing efficiency, and novel formula design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

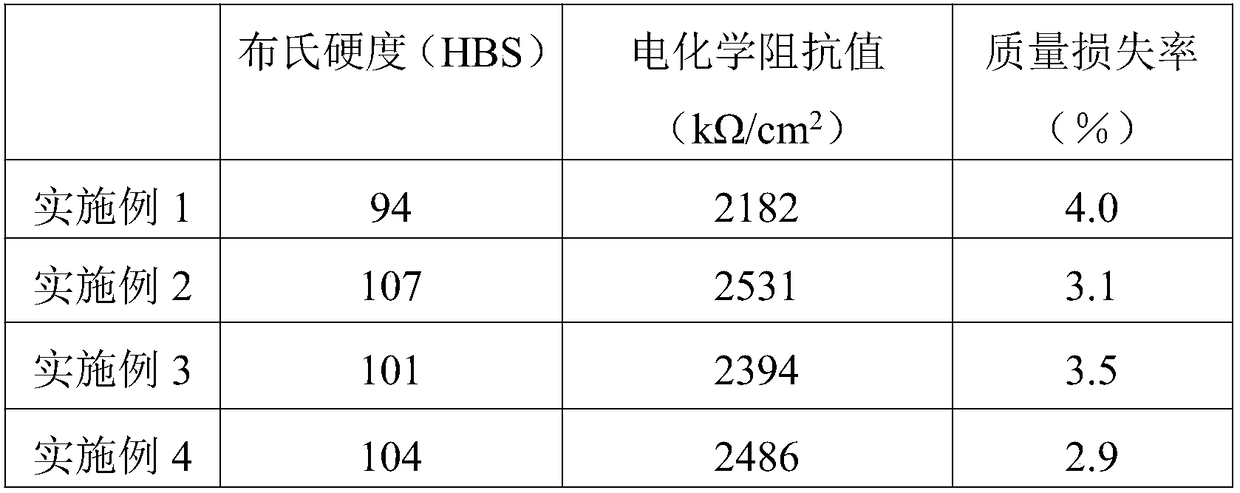

Examples

Embodiment 1

[0050] A method for preparing a corrosion-resistant treatment liquid for aluminum alloys, comprising the following steps:

[0051] (1) Weigh each raw material by weight: 1.5 parts of rare earth salt, 0.6 part of fluozirconic acid, 0.4 part of fluotitanic acid, 1 part of sodium tungstate, 3.5 parts of ammonium fluoroborate, 2 parts of zinc dihydrogen phosphate, and 2 parts of oxidizing agent , 2 parts of potassium fluorosilicate, 2.5 parts of silane, 30 parts of ethanol, 1 part of ammonium molybdate, 0.15 parts of Gemini surfactant, 6 parts of aqueous emulsion, 50 parts of deionized water;

[0052] (2) Stir water-based emulsion, ethanol, silane, fluozirconic acid, and fluotitanic acid at a speed of 300r / min for 20min, then add rare earth salt and stir at a speed of 200r / min for 6min, then add oxidant, sodium tungstate, fluoboric acid Ammonium, potassium fluorosilicate, zinc dihydrogen phosphate, ammonium molybdate, Gemini surfactant, and deionized water were mixed uniformly at ...

Embodiment 2

[0060] A method for preparing a corrosion-resistant treatment liquid for aluminum alloys, comprising the following steps:

[0061] (1) Weigh each raw material by weight: 1.5 parts of rare earth salt, 0.6 part of fluozirconic acid, 0.4 part of fluotitanic acid, 1 part of sodium tungstate, 3.5 parts of ammonium fluoroborate, 2 parts of zinc dihydrogen phosphate, and 2 parts of oxidizing agent , 2 parts of potassium fluorosilicate, 2.5 parts of silane, 30 parts of ethanol, 1 part of ammonium molybdate, 0.15 parts of Gemini surfactant, 6 parts of aqueous emulsion, 50 parts of deionized water;

[0062] (2) Stir water-based emulsion, ethanol, silane, fluozirconic acid, and fluotitanic acid at a speed of 300r / min for 20min, then add rare earth salt and stir at a speed of 200r / min for 6min, then add oxidant, sodium tungstate, fluoboric acid Ammonium, potassium fluorosilicate, zinc dihydrogen phosphate, ammonium molybdate, Gemini surfactant, and deionized water were mixed uniformly at ...

Embodiment 3

[0071] A method for preparing a corrosion-resistant treatment liquid for aluminum alloys, comprising the following steps:

[0072] (1) Weigh each raw material by weight: 1.5 parts of rare earth salt, 0.6 part of fluozirconic acid, 0.4 part of fluotitanic acid, 1 part of sodium tungstate, 3.5 parts of ammonium fluoroborate, 2 parts of zinc dihydrogen phosphate, and 2 parts of oxidizing agent , 2 parts of potassium fluorosilicate, 2.5 parts of silane, 30 parts of ethanol, 1 part of ammonium molybdate, 0.15 parts of Gemini surfactant, 6 parts of aqueous emulsion, 50 parts of deionized water;

[0073] (2) Stir water-based emulsion, ethanol, silane, fluozirconic acid, and fluotitanic acid at a speed of 300r / min for 20min, then add rare earth salt and stir at a speed of 200r / min for 6min, then add oxidant, sodium tungstate, fluoboric acid Ammonium, potassium fluorosilicate, zinc dihydrogen phosphate, ammonium molybdate, Gemini surfactant, and deionized water were mixed uniformly at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| loss rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com