Viscosity reducer for chlorinated natural rubber water-based paint and preparation method thereof

A technology of chlorinated natural rubber and water-based coatings, applied in the direction of rubber derivative coatings, coatings, etc., can solve the problems of uniform dispersion, inability to break emulsion particles, not a kind of stability, etc., and achieve the effect of high-efficiency viscosity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

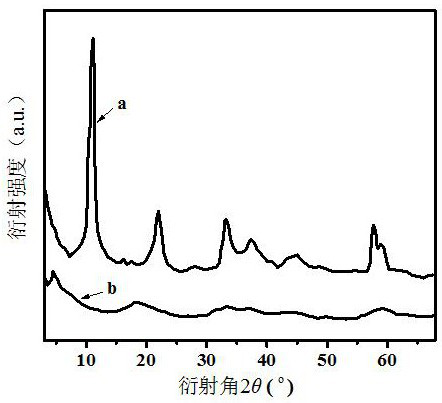

Image

Examples

Embodiment 1

[0028] Present embodiment is used for the preparation method of the viscosity reducer of chlorinated natural rubber water-based paint, and concrete steps are as follows:

[0029] (1) Take a certain amount of Mg(NO 3 ) 2 ·6H 2 O and Fe(NO 3 ) 3 9H 2 O dissolves in the removed CO 2 Solution A was prepared in deionized water, Mg(NO 3 ) 2 ·6H 2 O and Fe(NO 3 ) 3 9H 2 The ratio of O and deionized water is 2:1:13;

[0030] (2) Add sodium lignosulfonate to the solution A prepared in step (1), stir for 5 minutes at 22°C, and the stirring speed is 1000rpm, then add 1.0mol / L NaOH solution dropwise to the mixed solution while stirring to adjust Mixed solution pH to 8.0, obtain mixed solution B, wherein sodium lignosulfonate and Fe(NO in mixed solution B 3 ) 3 9H 2 O The ratio of the amount of both substances is 3.5:1;

[0031] (3) Nitrogen was passed through the mixture B obtained in step (2) for 5 minutes, then the mixture was placed in a closed container, and the closed...

Embodiment 2

[0033] Present embodiment is used for the preparation method of the viscosity reducer of chlorinated natural rubber water-based paint, and concrete steps are as follows:

[0034] (1) Take a certain amount of Mg(NO 3 ) 2 ·6H 2 O and Fe(NO 3 ) 3 9H 2 O dissolves in the removed CO 2 Solution A was prepared in deionized water, Mg(NO 3 ) 2 ·6H 2 O and Fe(NO 3 ) 3 9H 2 The ratio of O and deionized water is 2.5:1:20;

[0035] (2) Add sodium lignosulfonate to the solution A prepared in step (1), stir for 20 minutes at 23°C, and the stirring speed is 2000rpm, then add 2.0mol / L NaOH solution dropwise to the mixed solution while stirring to adjust Mixed solution pH to 8.5, obtain mixed solution B, wherein the sodium lignosulfonate and Fe(NO in mixed solution B 3 ) 3 9H 2 O The ratio of the amount of both substances is 3:1;

[0036] (3) Nitrogen was passed through the mixed solution B obtained in step (2) for 8 minutes, then the mixed solution was placed in a closed contai...

Embodiment 3

[0038] Present embodiment is used for the preparation method of the viscosity reducer of chlorinated natural rubber water-based paint, and concrete steps are as follows:

[0039] (1) Take a certain amount of Mg(NO 3 ) 2 ·6H 2 O and Fe(NO 3 ) 3 9H 2 O dissolves in the removed CO 2 Solution A was prepared in deionized water, Mg(NO 3 ) 2 ·6H 2 O and Fe(NO 3 ) 3 9H 2 The ratio of O and deionized water is 3.5:1:25;

[0040] (2) Add sodium lignosulfonate to the solution A prepared in step (1), stir for 40 minutes at 24°C, and the stirring speed is 3000rpm, then add 3.0mol / L NaOH solution dropwise to the mixed solution while stirring to adjust Mixed solution pH to 9.0, obtain mixed solution B, wherein the sodium lignosulfonate and Fe(NO in mixed solution B 3 ) 3 9H 2 O The ratio of the amount of both substances is 3.2:1;

[0041] (3) Nitrogen was passed through the mixed solution B obtained in step (2) for 10 minutes, then the mixed solution was placed in a closed con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com