Viscosity reducer for chlorinated natural rubber waterborne paint and preparation method thereof

A technology of chlorinated natural rubber and water-based coatings, applied in rubber derivative coatings, coatings, etc., can solve the problems of uniform dispersion, non-stabilization, phase separation, etc., and achieve the effect of high-efficiency viscosity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

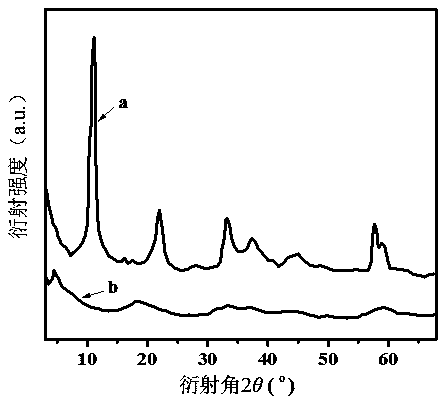

Image

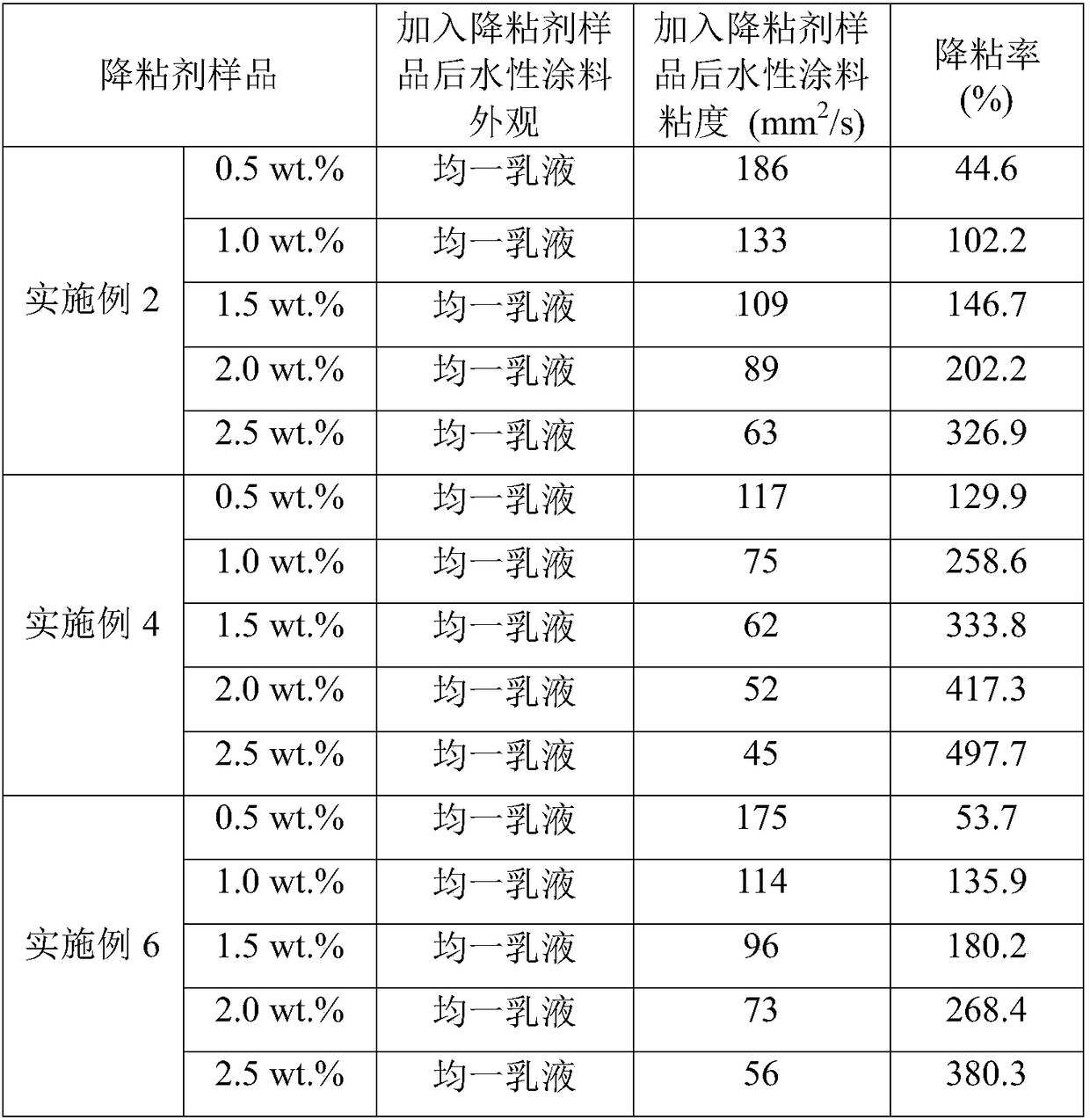

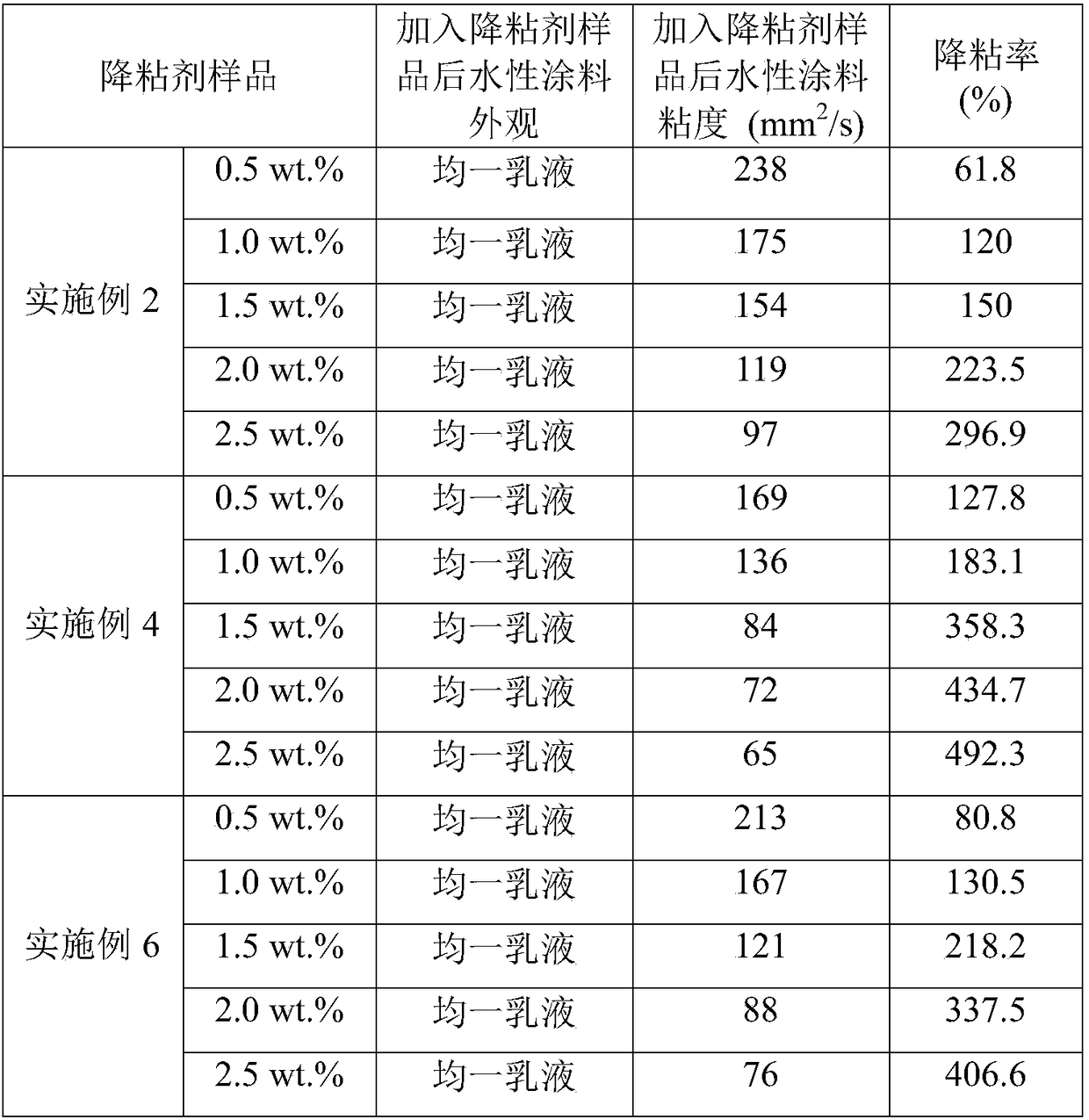

Examples

Embodiment 1

[0028] This embodiment is used in the preparation method of the viscosity reducer for chlorinated natural rubber water-based paint, and the specific steps are as follows:

[0029] (1) Take a certain amount of Mg(NO 3 ) 2 ·6H 2 O and Fe(NO 3 ) 3 ·9H 2 O soluble in CO removed 2 Of deionized water into solution A, Mg(NO 3 ) 2 ·6H 2 O and Fe(NO 3 ) 3 ·9H 2 The ratio of the amount of O and deionized water is 2:1:13;

[0030] (2) Add sodium lignosulfonate to the solution A prepared in step (1), stir at 22°C for 5 min at a stirring speed of 1000 rpm, and then add 1.0 mol / L NaOH solution dropwise to the mixed solution while stirring to adjust The pH of the mixed solution is 8.0, and mixed solution B is obtained, in which the sodium lignosulfonate and Fe(NO 3 ) 3 ·9H 2 The ratio of the amount of the two substances is 3.5:1;

[0031] (3) Blow nitrogen into the mixture B obtained in step (2) for 5 minutes, then place the mixture in a closed container, and react in the closed container at 90°C f...

Embodiment 2

[0033] This embodiment is used in the preparation method of the viscosity reducer for chlorinated natural rubber water-based paint, and the specific steps are as follows:

[0034] (1) Take a certain amount of Mg(NO 3 ) 2 ·6H 2 O and Fe(NO 3 ) 3 ·9H 2 O soluble in CO removed 2 Solution A, Mg(NO 3 ) 2 ·6H 2 O and Fe(NO 3 ) 3 ·9H 2 The ratio of the amount of O and deionized water is 2.5:1:20;

[0035] (2) Add sodium lignosulfonate to the solution A prepared in step (1), stir at 23°C for 20 minutes at a stirring speed of 2000 rpm, and then add 2.0mol / L NaOH solution dropwise to the mixed solution while stirring to adjust The pH of the mixed solution is 8.5, and mixed solution B is obtained, in which the sodium lignosulfonate and Fe(NO 3 ) 3 ·9H 2 The ratio of the amount of the two substances is 3:1;

[0036] (3) Blow nitrogen gas into the mixture B obtained in step (2) for 8 minutes, then place the mixture in a closed container, and react in the closed container at 95°C for 30 hours, and...

Embodiment 3

[0038] This embodiment is used for the preparation method of the viscosity reducer of chlorinated natural rubber water-based paint, and the specific steps are as follows:

[0039] (1) Take a certain amount of Mg(NO 3 ) 2 ·6H 2 O and Fe(NO 3 ) 3 ·9H 2 O soluble in CO removed 2 Solution A, Mg(NO 3 ) 2 ·6H 2 O and Fe(NO 3 ) 3 ·9H 2 The ratio of the amount of O and deionized water is 3.5:1:25;

[0040] (2) Add sodium lignosulfonate to the solution A prepared in step (1), stir at 24°C for 40 minutes at a stirring speed of 3000 rpm, and then add 3.0 mol / L NaOH solution dropwise to the mixture while stirring to adjust The pH of the mixed solution is 9.0, and mixed solution B is obtained. The sodium lignosulfonate and Fe(NO 3 ) 3 ·9H 2 The ratio of the amount of the two substances is 3.2:1;

[0041] (3) Blow nitrogen into the mixture B obtained in step (2) for 10 minutes, then place the mixture in a closed container, and react in the closed container at 95°C for 20 hours, and then filter the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com