Color-changing organic-inorganic hybrid material, and preparation method and application of material

A hybrid material and inorganic technology, applied in the field of color-changing organic-inorganic hybrid materials and their preparation, can solve the problems of high detection cost, insufficient sensitivity, and complicated operation, and achieve the effects of high sensitivity, simple raw materials, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

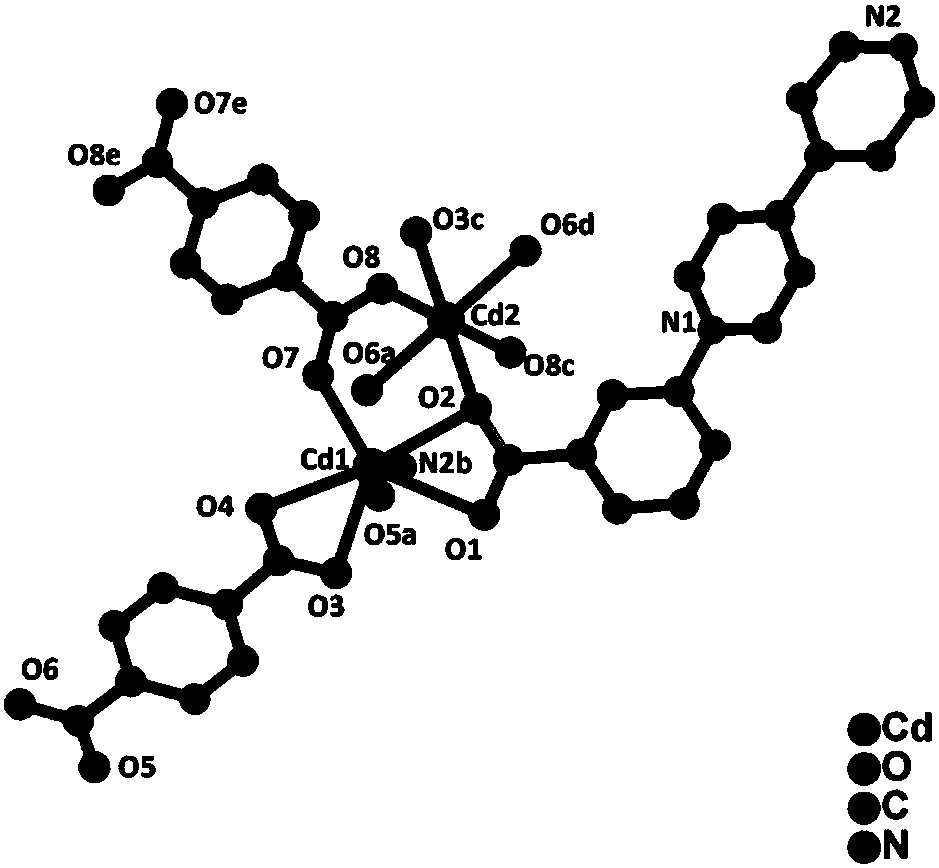

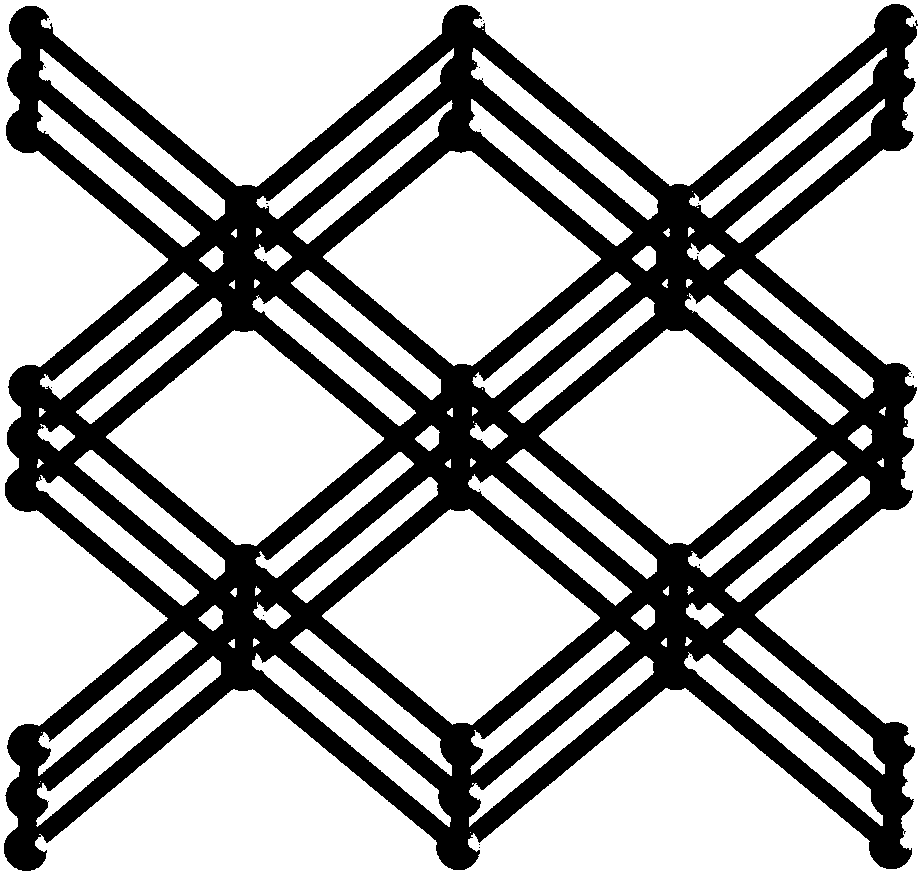

[0032] The preparation method of the color-changing organic-inorganic hybrid material of the present invention includes the following steps:

[0033] S1. Weigh cadmium nitrate, terephthalic acid and monochloro-3-benzoic acid-4,4'-bipyridine according to a certain molar ratio and mix, add the mixture to the solvent, and stir under air atmosphere The solvothermal reaction is carried out after 30 minutes, the reaction temperature is 100°C, and the reaction time is 5-10 days. After the reaction is completed, it is cooled at a rate of 5-10°C / h, filtered and washed to obtain yellow block crystals;

[0034] S2. Put the crystal material obtained from S1 into a Shrek tube, evacuate until the oxygen content does not exceed 0.06ppm, and then irradiate the sample with a high-pressure mercury lamp. The sample in the tube turns from yellow to light blue, which is a color-changing organic Inorganic hybrid materials.

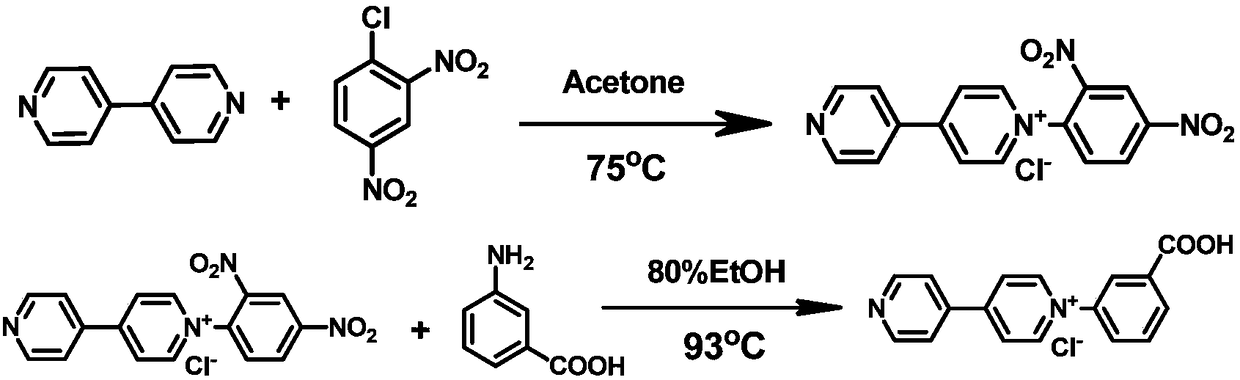

[0035] Furthermore, the synthetic route of monochloro-3-benzoic acid-4,4'-bipyri...

Embodiment 1

[0044] First, 2,4-dinitrochlorobenzene (16.16g, 78mmol) and 4,4'-bipyridine (12.40g, 78mmol) were dissolved in 80ml of acetone, and heated and stirred for 24h at 75℃ to obtain a light gray product Monochloro-1-(2,4-dinitrophenyl)-4,4'-bipyridine; followed by 5.0g monochloro-1-(2,4-dinitrophenyl)-4 Add 200ml ethanol to 4'-bipyridine, then add 2.8ml triethylamine, stir for 30 minutes, add 1.50g m-aminobenzoic acid, and react at 93°C for 48h. The solvent was removed by rotary evaporation, then water was added, stirred for 1 hour, and vacuum filtered. After suction filtered, water was added to dissolve, drop acetone to the solid powder, vacuum filtered, and the solid powder obtained was monochloro-3-benzoic acid. -4,4'-Bipyridine.

[0045] Then cadmium nitrate (0.155g, 0.5mmol), terephthalic acid (0.082g, 0.5mmol) and chloro-3-benzoic acid group-4,4'-bipyridine (0.056g, 0.2mmol) were dissolved in In a solvent prepared by mixing ethanol (2mL), water (1mL) and N,N'-dimethylformamide ...

Embodiment 2

[0047] The preparation method is the same as in Example 1, except that the reaction time of cadmium nitrate, terephthalic acid and monochloro-3-benzoyl-4,4'-bipyridine in the solvent is 10 days, and the cooling rate is 10°C / h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com