Wide temperature range type high-temperature lead-free ceramic capacitor material and preparation method

A technology of ceramic capacitors and lead-free ceramics, applied in capacitors, fixed capacitors, fixed capacitor dielectrics, etc., can solve problems such as poor temperature stability, large lead pollution, environmental and human hazards, etc., to reduce dielectric loss and improve dielectric Constant, environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

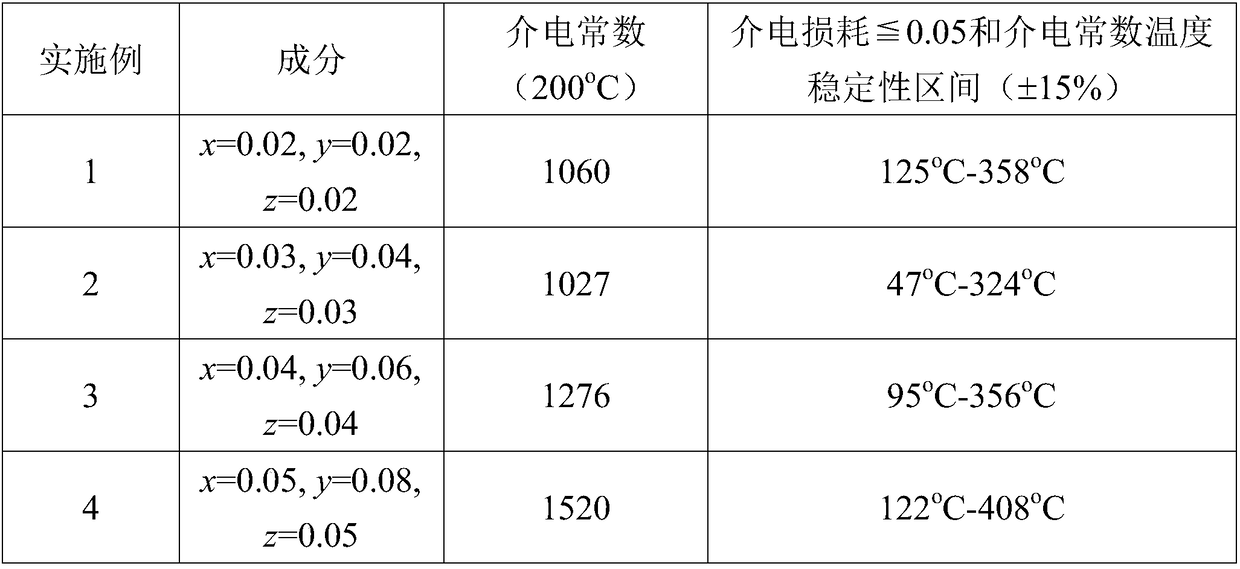

Examples

Embodiment 1

[0018] (1) According to the chemical formula, it is 0.92(K 0.5 Na 0.5 )NbO 3 -0.90LiNbO 3 -0.02SrTiO 3 , weigh the corresponding oxide (Nb 2 o 5 and TiO 2 ) and carbonate (K 2 CO 3 、Na 2 CO 3 , Li 2 CO 3 and SrCO 3 ) raw materials, mixed by ball milling, dried, pressed into a column and kept warm at 1100 degrees Celsius for 2 hours, and ground to obtain powder particles for later use;

[0019] (2) Prepare 0.02(Bi 0.5 Li 0.5 )ZrO 3 -0.02CuO, first use analytically pure bismuth nitrate, lithium nitrate, and copper nitrate to weigh the ingredients at a ratio of 1:1:2, dissolve them in ethylene glycol monomethyl ether, and the mass of ethylene glycol monomethyl ether is 3% of the ingredients. times, a homogeneous solution (A solution) was obtained;

[0020] (3) Then according to the Bi:Zr molar ratio of 1:2, measure the corresponding amount of tetrabutyl zirconate with a graduated cylinder and dissolve it in absolute ethanol. The volume of ethanol is 3 times the v...

Embodiment 2

[0027] (1) According to the chemical formula, it is 0.92(K 0.5 Na 0.5 )NbO 3 -0.89LiNbO 3 -0.03SrTiO 3 , weigh the corresponding oxide (Nb 2 o 5 and TiO 2 ) and carbonate (K 2 CO 3 、Na 2 CO 3 , Li 2 CO 3 and SrCO 3 ) raw materials, mixed by ball milling, dried, pressed into a column and kept warm at 1120 degrees Celsius for 2 hours, and ground to obtain powder particles for later use;

[0028] (2) Prepare 0.04(Bi 0.5 Li 0.5 ) ZrO 3 -0.03CuO, first use analytically pure bismuth nitrate, lithium nitrate, and copper nitrate to weigh the ingredients according to 2:2:3, dissolve them in ethylene glycol monomethyl ether, and the mass of ethylene glycol monomethyl ether is 4% of the ingredients. times, a homogeneous solution (A solution) was obtained;

[0029] (3) Then according to the Bi:Zr molar ratio of 1:2, measure the corresponding amount of tetrabutyl zirconate with a graduated cylinder and dissolve it in absolute ethanol. The volume of ethanol is 4 times the v...

Embodiment 3

[0036] (1) According to the chemical formula, it is 0.92(K 0.5 Na 0.5 )NbO 3 -0.88LiNbO 3 -0.04SrTiO 3 , weigh the corresponding oxide (Nb 2 o 5 and TiO 2 ) and carbonate (K 2 CO 3 、Na 2 CO 3 , Li 2 CO 3 and SrCO 3 ) raw materials, mixed by ball milling, dried, pressed into a column and kept at 1140 degrees Celsius for 2 hours, and ground to obtain powder particles for later use;

[0037] (2) Prepare 0.06(Bi 0.5 Li 0.5 )ZrO 3 -0.04CuO, first use analytically pure bismuth nitrate, lithium nitrate, and copper nitrate to weigh the ingredients according to 3:3:4, dissolve them in ethylene glycol monomethyl ether, and the mass of ethylene glycol monomethyl ether is 5% of the ingredients. times, a homogeneous solution (A solution) was obtained;

[0038] (3) Then according to the Bi:Zr molar ratio of 1:2, use a graduated cylinder to measure the corresponding amount of tetrabutyl zirconate and dissolve it in absolute ethanol. The volume of ethanol is 5 times the volum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com