Filter press device for electroplating metal from solutions, which is formed by separating elements formed by ion-exchange membranes, forming a plurality of anolyte and catholyte chambers, the electrodes being connected in series with automatic detachment of the metallic product

A catholyte and anolyte technology, applied in the direction of electrolysis components, electrodes, electrolysis process, etc., can solve the problems of passivation layer, high pumping cost, huge factory scale, etc., to improve kinetics and reduce energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

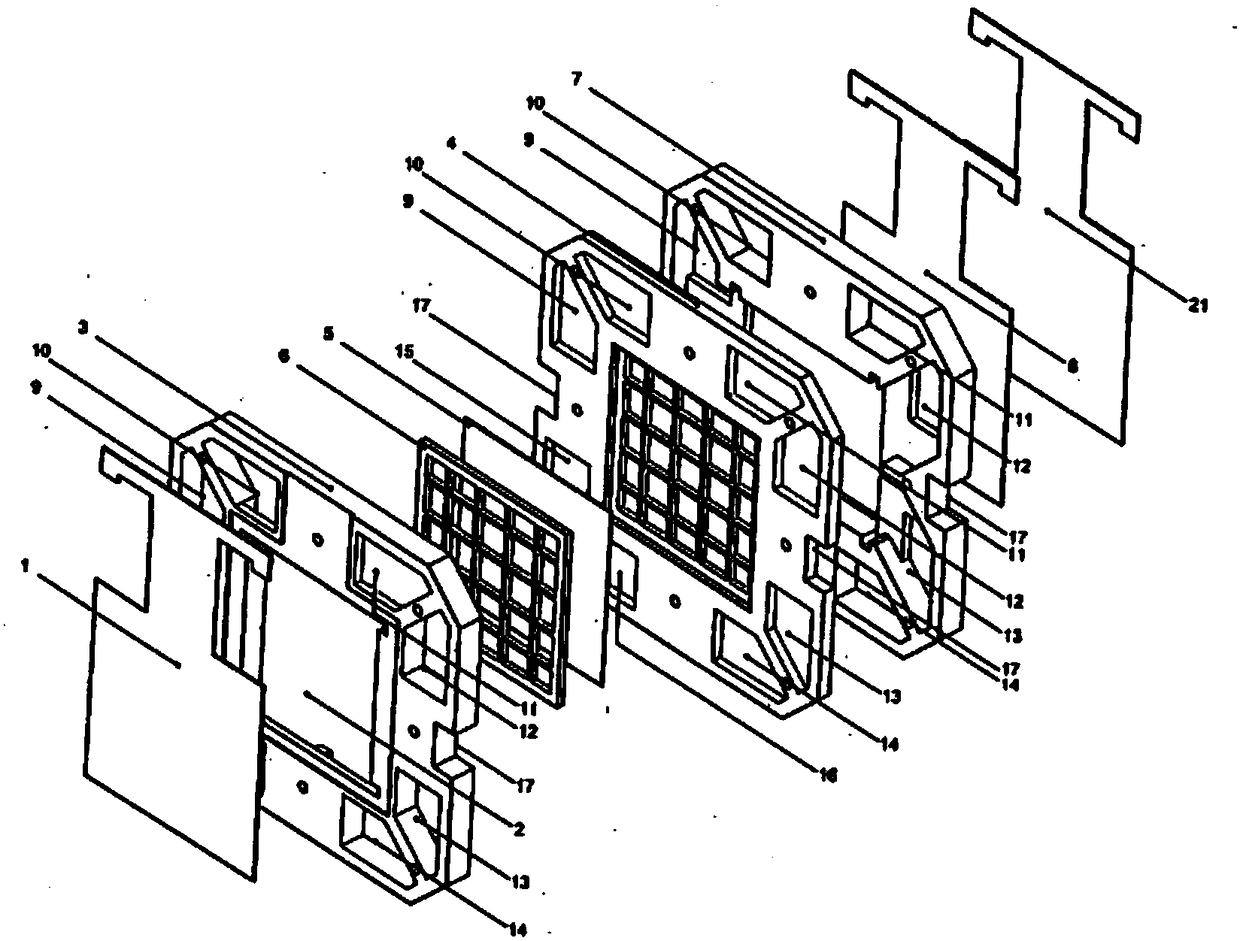

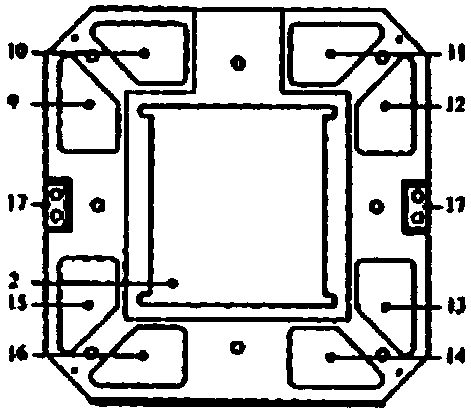

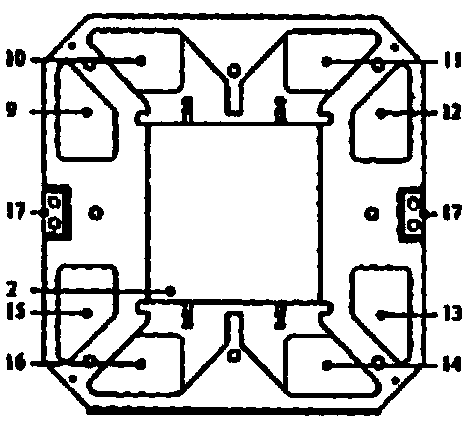

[0056] refer to figure 1 Electrowinning device, the cathode comprising a plate (1) completely covering the central opening and being the active surface of the cathode, which is the space (2) through which the catholyte circulates through its frame (3). Adjacent to this frame (3) are frames (4) arranged in rows on a plane parallel to the plane of the plate (1). In the frame (4), in the space corresponding to the central opening (2), it includes an ion exchange membrane (5), an open space (2), wherein both sides of the ion exchange membrane (5) are supported by grids (6) and prevent fluid diversion from the circulation space of the anolyte corresponding to the frame (7), the open space (2) is completely covered by the active surface of the electrode wall (8) in contact with the anolyte as the anode, the anolyte is sealed The opening through which the anolyte flows. The opposite wall of the electrode, covered by an insulating rubber piece (21), which is separated from the catho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com