High temperature resistant multilayer piezoelectric ceramic actuator and preparation method and use thereof

A technology of piezoelectric ceramics and actuators, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, piezoelectric devices/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, etc., capable of Solve the problems of high price and high use temperature, and achieve the effect of low price, good high temperature resistance and lower sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

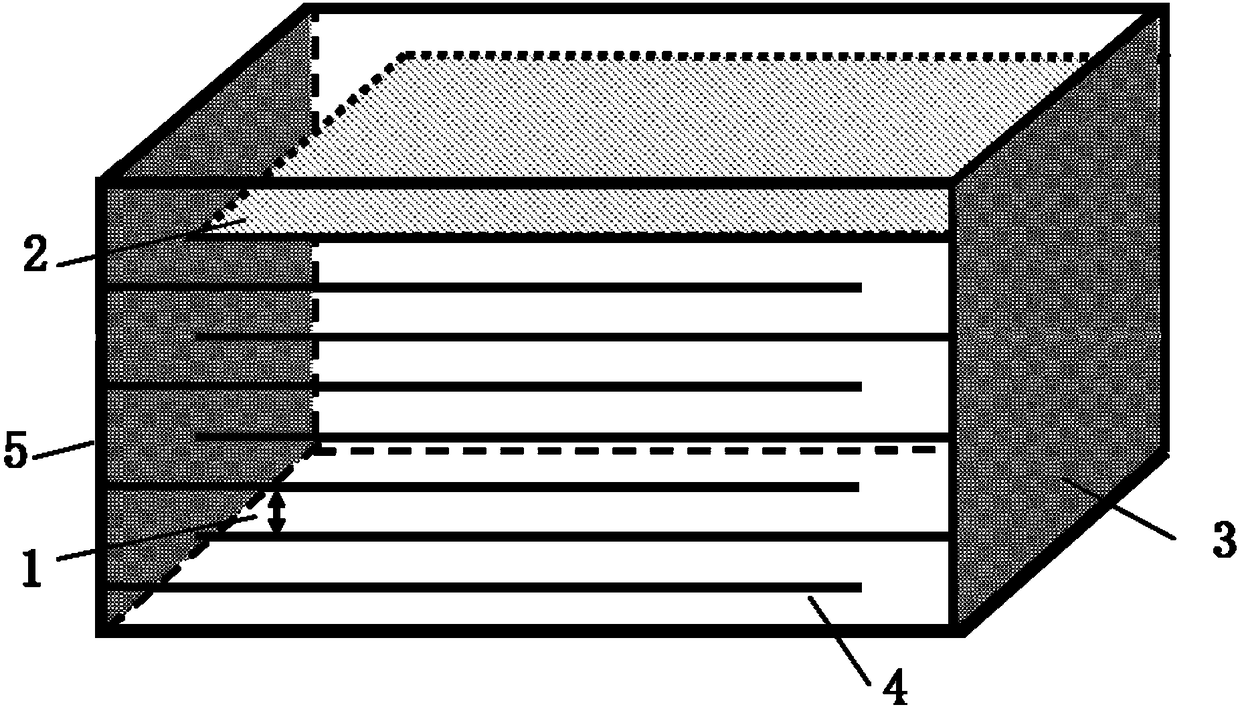

[0054] The specific preparation process of the high temperature resistant multilayer piezoelectric ceramic actuator of this embodiment is as follows:

[0055] (1) will Bi 2 o 3 , Sc 2 o 3 , PbO and TiO 2 By component 0.3BiScO 3 -0.7PbTiO 3 Weighing the molar ratio, and wet ball milling, heating and calcining (pre-calcining) the obtained mixture powder at a temperature of 750°C to 800°C, and keeping it warm for 2 hours to obtain the calcined powder;

[0056] (2) Add 0.1wt% sintering aid CuO of the calcined powder mass to the calcined powder obtained in step (1), and wet ball mill, and tape-cast the obtained mixture to obtain a ceramic diaphragm;

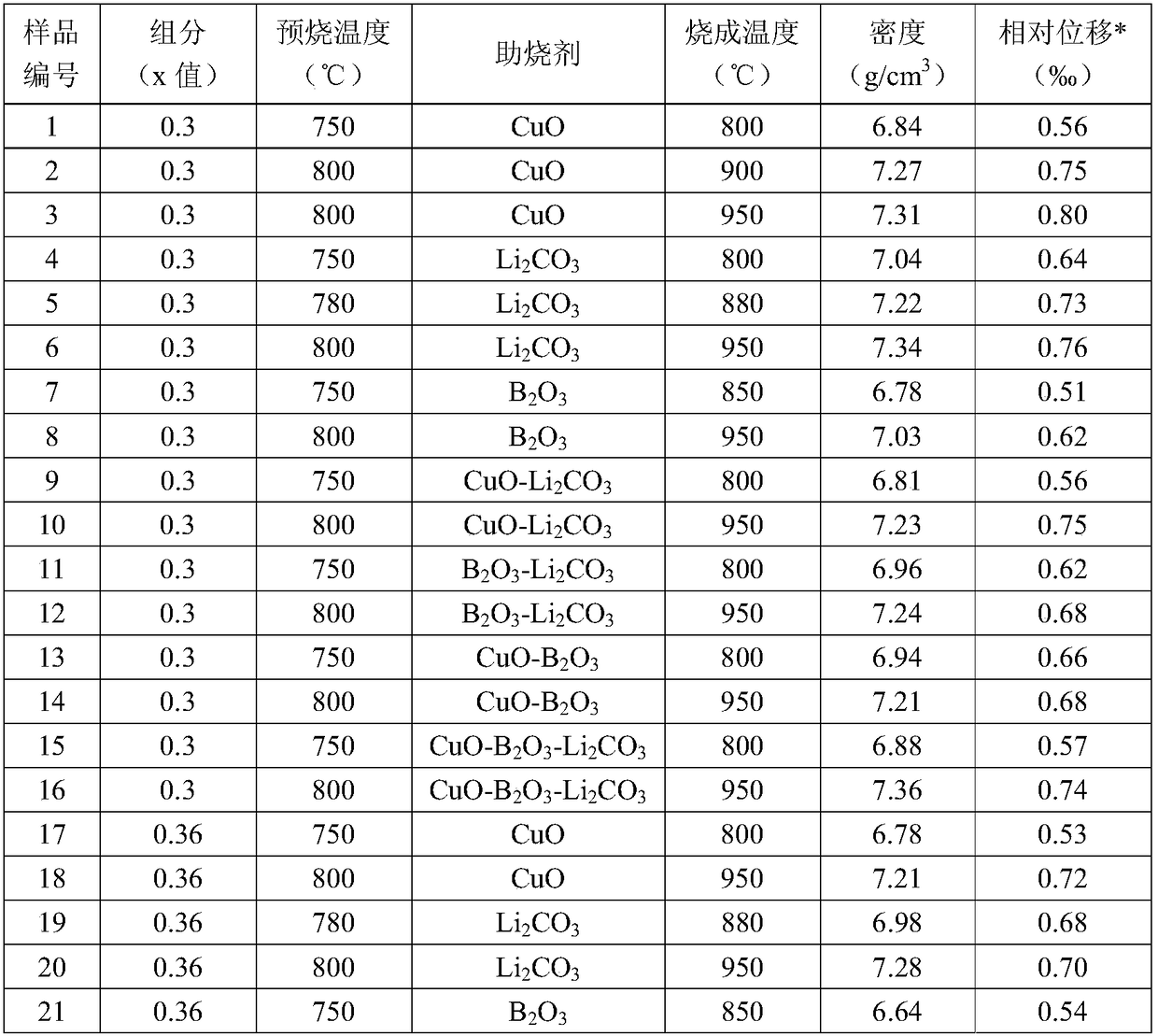

[0057] (3) The ceramic diaphragm obtained in step (2) is screen-printed to obtain a ceramic diaphragm with an internal silver electrode, and the layered ceramic diaphragm with an internal silver electrode pattern is laminated and heated at 800°C to 950°C The temperature is kept at a temperature range of 2 hours for firing, and ...

Embodiment 2

[0065] The specific preparation process of the high-temperature-resistant multilayer piezoelectric ceramic actuator of this embodiment refers to Example 1, the difference is that in step (2), the sintering aid is Li 2 CO 3 .

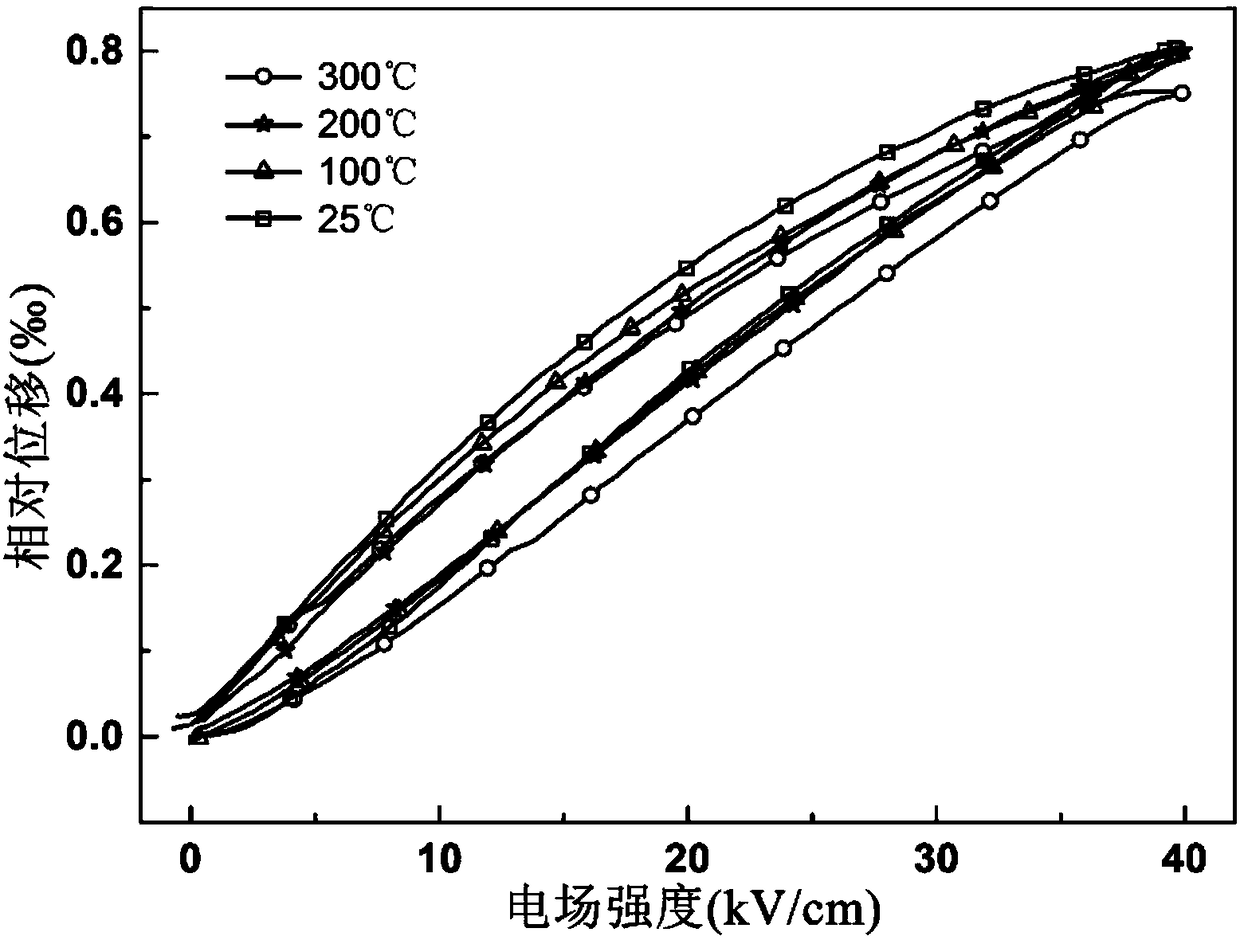

[0066] In the multilayer piezoelectric ceramic actuator sample obtained in this embodiment, the ceramic layer 1 is made of high temperature piezoelectric ceramic material 0.3BiScO 3 -0.7PbTiO 3 and burning aid Li 2 CO 3 Composition, the mass of the sintering aid is 0.1wt% of the mass of the high-temperature piezoelectric ceramic material, the internal electrode is a silver electrode, and the structure of the multilayer piezoelectric ceramic actuator sample is the same as that of the sample in Example 1. The specific test parameters and performance test results of Sample 4, Sample 5 and Sample 6 obtained in this embodiment are listed in Table 1.

[0067] All the samples obtained in this embodiment are applicable to the working temperature range of 25° ...

Embodiment 3

[0069] The specific preparation process of the high-temperature-resistant multilayer piezoelectric ceramic actuator of this embodiment refers to Example 1, the difference is that in step (2), the sintering aid is B 2 o 3 .

[0070] In the multilayer piezoelectric ceramic actuator sample obtained in this embodiment, the ceramic layer 1 is made of high temperature piezoelectric ceramic material 0.3BiScO 3 -0.7PbTiO 3 and burning aid B 2 o 3 Composition, the mass of the sintering aid is 0.1wt% of the mass of the high-temperature piezoelectric ceramic material, the internal electrode is a silver electrode, and the structure of the multilayer piezoelectric ceramic actuator sample is the same as that of the sample in Example 1. The specific test parameters and performance test results of samples 7 and 8 obtained in this embodiment are listed in Table 1.

[0071] All the samples obtained in this embodiment are applicable to the working temperature range of 25° C. to 300° C., and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com