Method for improving fire resistance and mechanical property of polyethylene/nylon 6 blend

A polyethylene and blend technology, which is applied in the field of preparation of polymer composite materials, can solve the problem that flame retardant performance and compatibilization efficiency cannot be taken into account at the same time, and achieve the purpose of improving application value, improving flame retardant performance, and improving mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

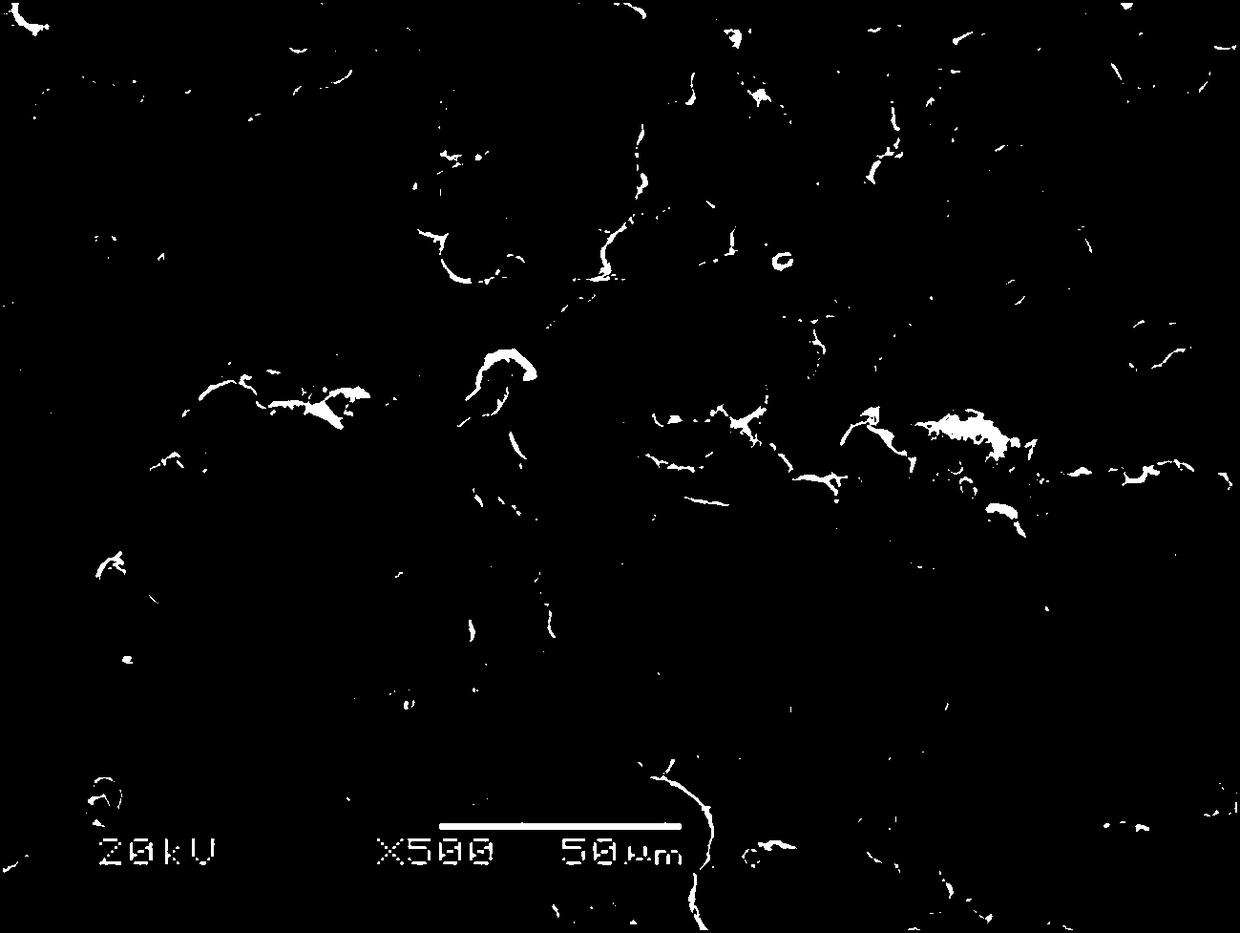

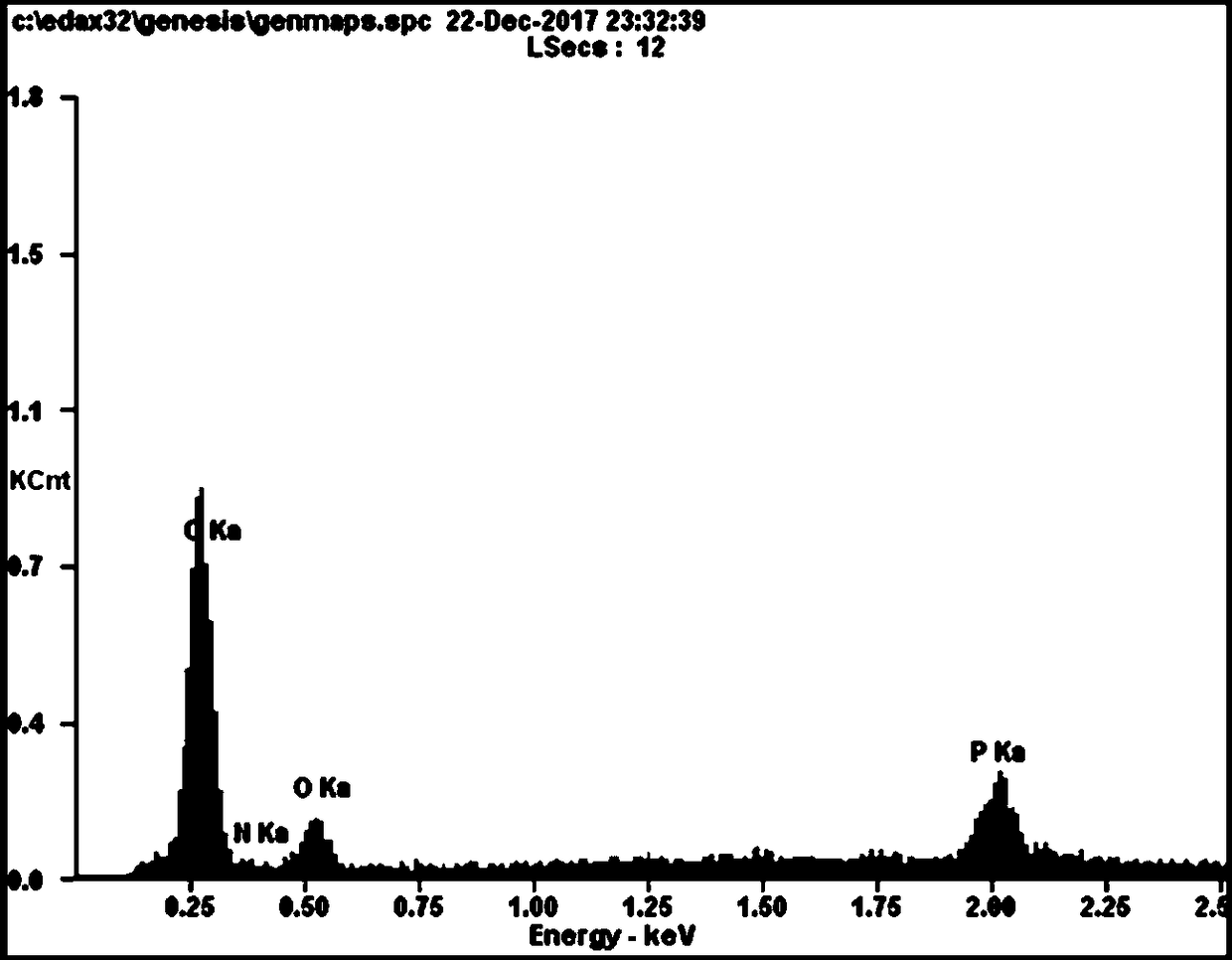

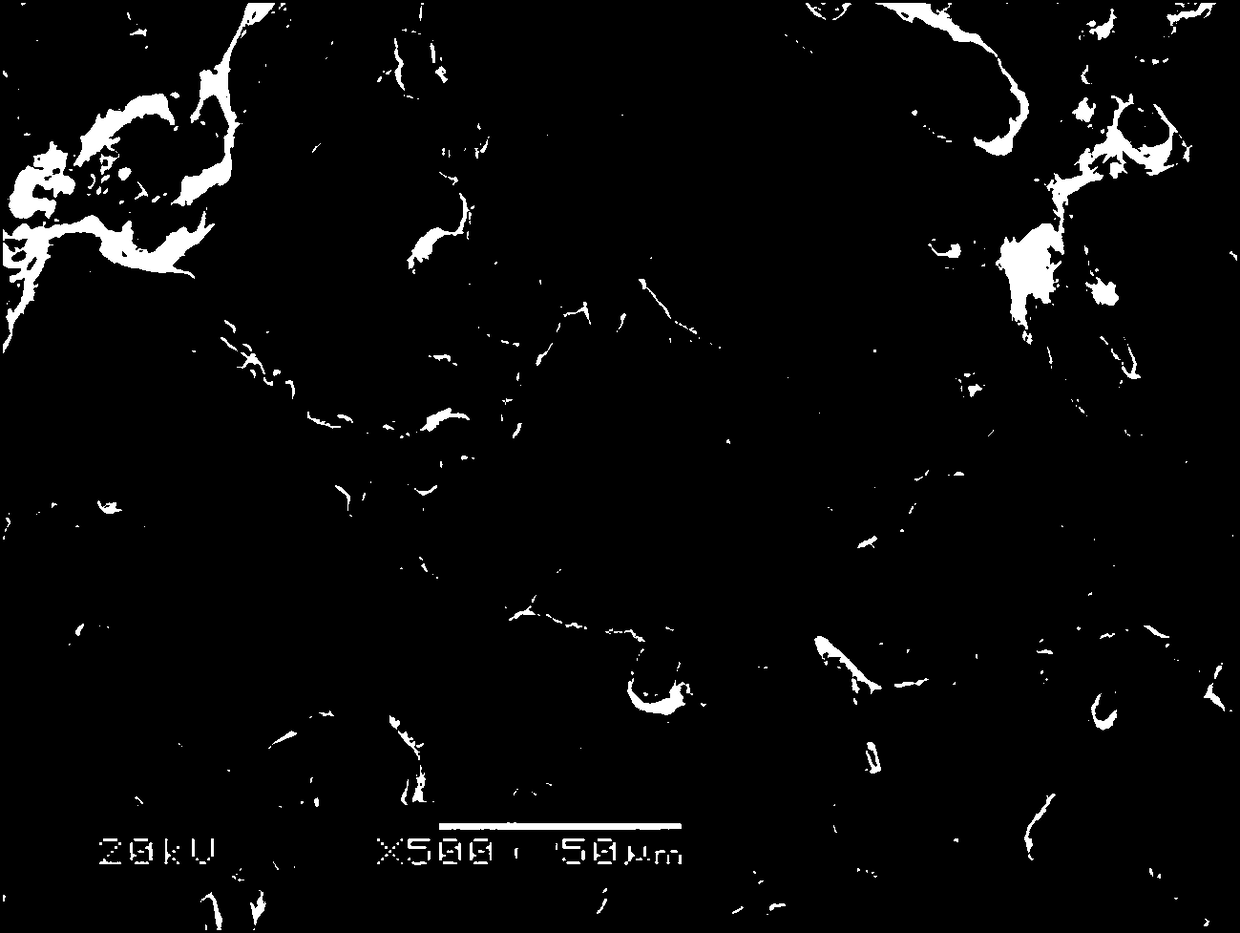

Image

Examples

Embodiment 1

[0038] The polyethylene / nylon 6 blend of present embodiment adopts following method to make:

[0039]Weigh a certain amount of linear low density polyethylene (LLDPE), nylon 6 (PA6), PE-g-MAH (solubilizer), ammonium polyphosphate (APP), pentaerythritol according to the ratio of 62:16:2:16:4 (PER), within the temperature range of 220~240°C, the twin-screw extruder is used to melt the mixed material to prepare the corresponding blend, and it is molded in the corresponding molding processing equipment at the temperature range of 220~240°C. Preparation of products. The mechanical properties and flame retardant properties tested are shown in Table 1.

Embodiment 2

[0041] The polyethylene / nylon 6 blend of present embodiment adopts following method to make:

[0042] Weigh a certain amount of linear low density polyethylene (LLDPE), nylon 6 (PA6), PE-g-MAH (solubilizer), ammonium polyphosphate (APP), pentaerythritol according to the ratio of 59:15:5:16:4 (PER), within the temperature range of 220~240°C, the twin-screw extruder is used to melt the mixed material to prepare the corresponding blend, and it is molded in the corresponding molding processing equipment at the temperature range of 220~240°C. Preparation of products. The mechanical properties and flame retardant properties tested are shown in Table 1.

Embodiment 3

[0044] The polyethylene / nylon 6 blend of present embodiment adopts following method to make:

[0045] Weigh a certain amount of linear low density polyethylene (LLDPE), nylon 6 (PA6), PE-g-MAH (solubilizer), ammonium polyphosphate (APP), pentaerythritol according to the ratio of 56:17:8:16:4 (PER), within the temperature range of 220~240°C, the twin-screw extruder is used to melt the mixed material to prepare the corresponding blend, and it is molded in the corresponding molding processing equipment at the temperature range of 220~240°C. Preparation of products. The mechanical properties and flame retardant properties tested are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com