Organic silica gel/three-dimensional graphene carbon nanocomposite-based small-sized pressure sensor

A nanocomposite material and carbon nanomaterial technology, applied in the field of sensors, can solve the problems of difficulty in exerting the performance advantages of single-layer graphene, inability to meet industrial application requirements, and high preparation costs, and achieve easy expansion of production, high output, and electrical conductivity. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

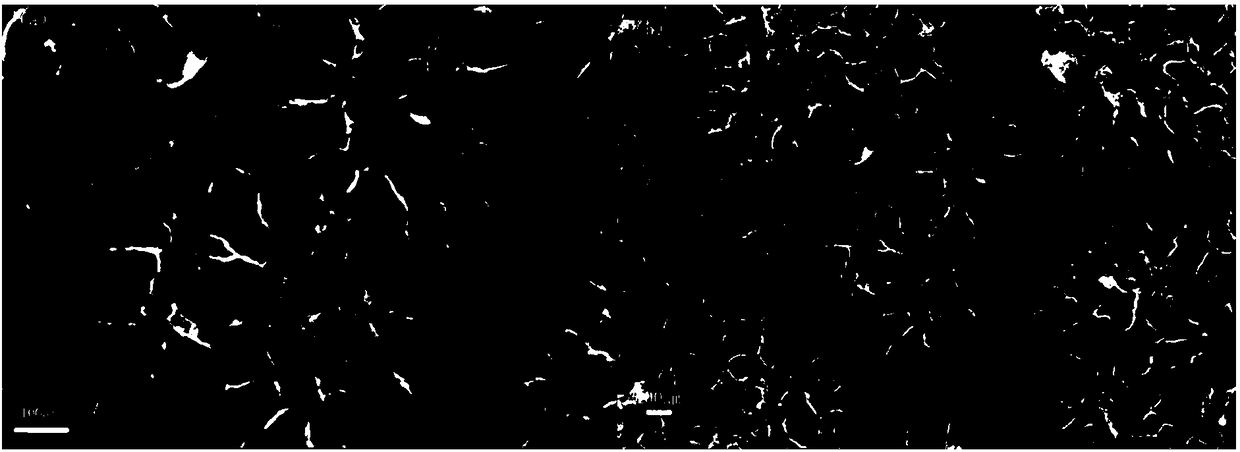

Image

Examples

Embodiment Construction

[0021] The present invention is described further below in conjunction with example, but the present invention is not limited to specific embodiment.

[0022] 1) Weigh 8 grams of magnesium powder and 42 grams of NaCl powder, mix them with a shaker in a plastic test tube, and then pour them into two large-sized corundum boats.

[0023] 2) Put the two ceramic boats containing the reactants into the furnace tube, pump air with a mechanical vacuum pump, and then fill it with argon, repeat twice to remove oxygen.

[0024] 3) Introduce argon gas into the liquid carbon disulfide container, and bubble the liquid at a flow rate of 200mL / min, Ar and CS 2 The mixed gas is passed into the tube furnace. At the same time, the furnace was heated up to 600°C at a rate of 15°C and held for 90 minutes. During the reaction, the tube furnace was pumped with a vacuum pump.

[0025] 4) After the reaction, the furnace was naturally cooled to room temperature, and the ceramic boat was taken out an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com