Vehicle anti-lock control system and slip ratio vibration suppression method based on LQG controller

A jitter suppression and anti-lock technology, applied in general control systems, control/regulation systems, brakes, etc., to solve problems such as decreased control effect, inability of hydraulic units to accurately execute control commands, and excessive wheel slip rate jitter.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

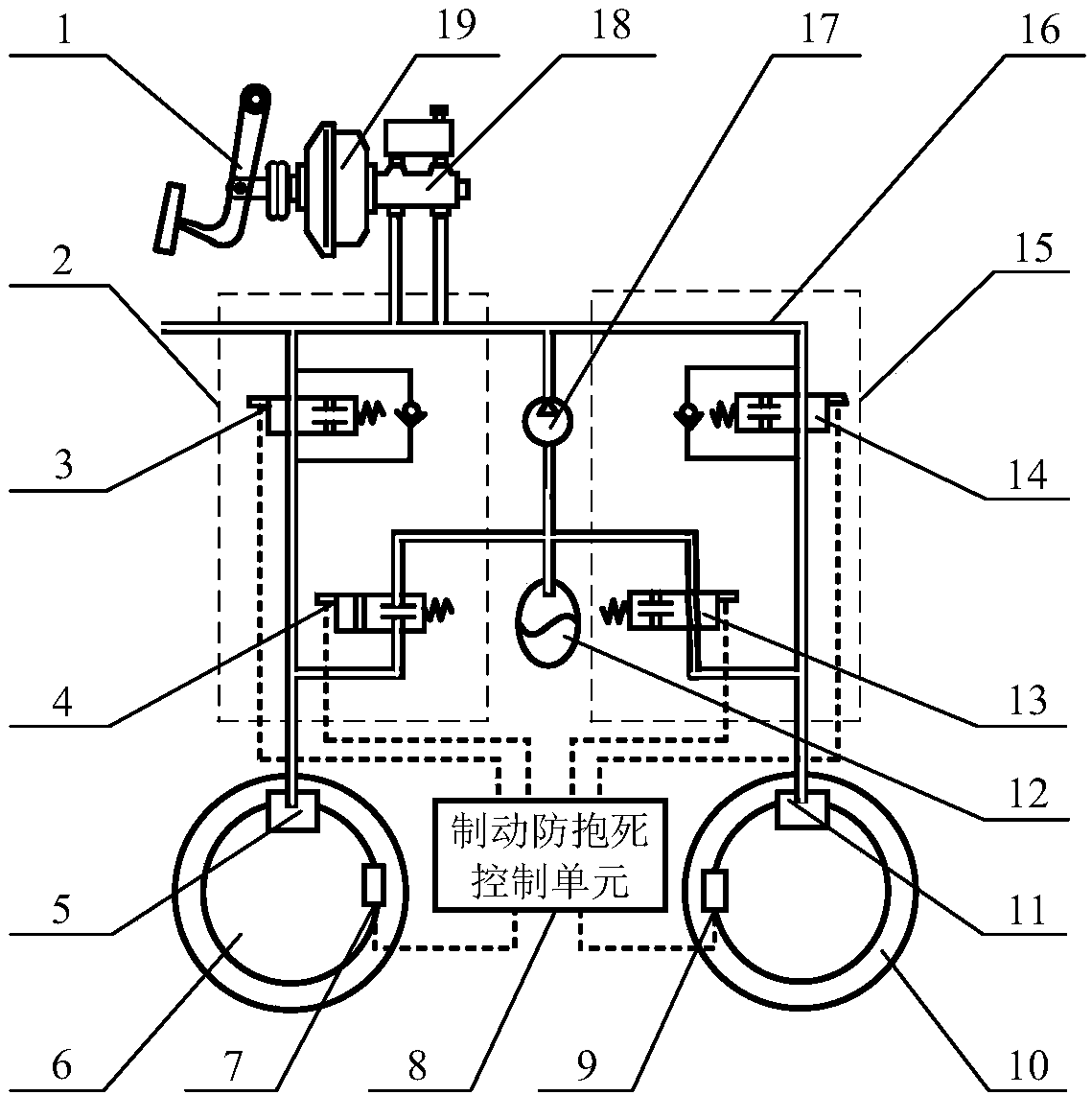

[0022] Such as figure 1 As shown, the vehicle anti-lock brake control system includes a brake pedal 1, a front wheel cylinder 5, a front wheel 6, a front wheel speed sensor 7, a brake anti-lock brake control unit 8, a rear wheel speed sensor 9, a rear wheel 10. Rear wheel cylinder 11, brake fluid accumulator 12, oil pipe 16, return pump 17, brake master cylinder with oil reservoir 18, brake booster 19, front wheel ABS actuator 2 and rear wheel ABS Executing mechanism 15; wherein the front wheel ABS actuator 2 includes two parts, the front wheel liquid inlet valve 3 and the front wheel liquid outlet valve 4, and the rear wheel ABS actuator 15 includes two parts: the rear wheel liquid outlet valve 13 and the rear wheel liquid inlet valve 14. The brake pedal 1 is connected to one end of the brake booster 19, and the other end of the brake boost...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com