Office quick-drying glue and preparation process thereof

A technology of glue and buffering agent, applied in the direction of adhesive type, adhesive additive, ester copolymer adhesive, etc., can solve the problem of long drying time of water, reduce the possibility of production safety accidents and improve utilization rate, reduce the effect of drying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

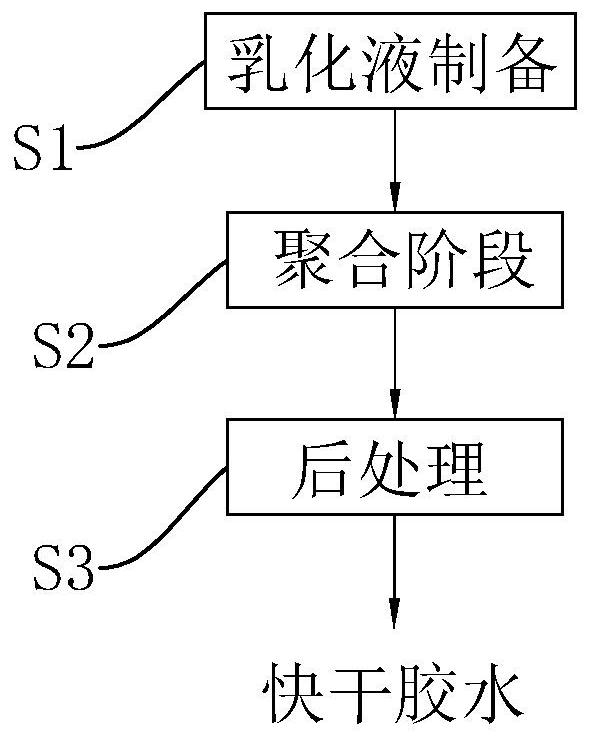

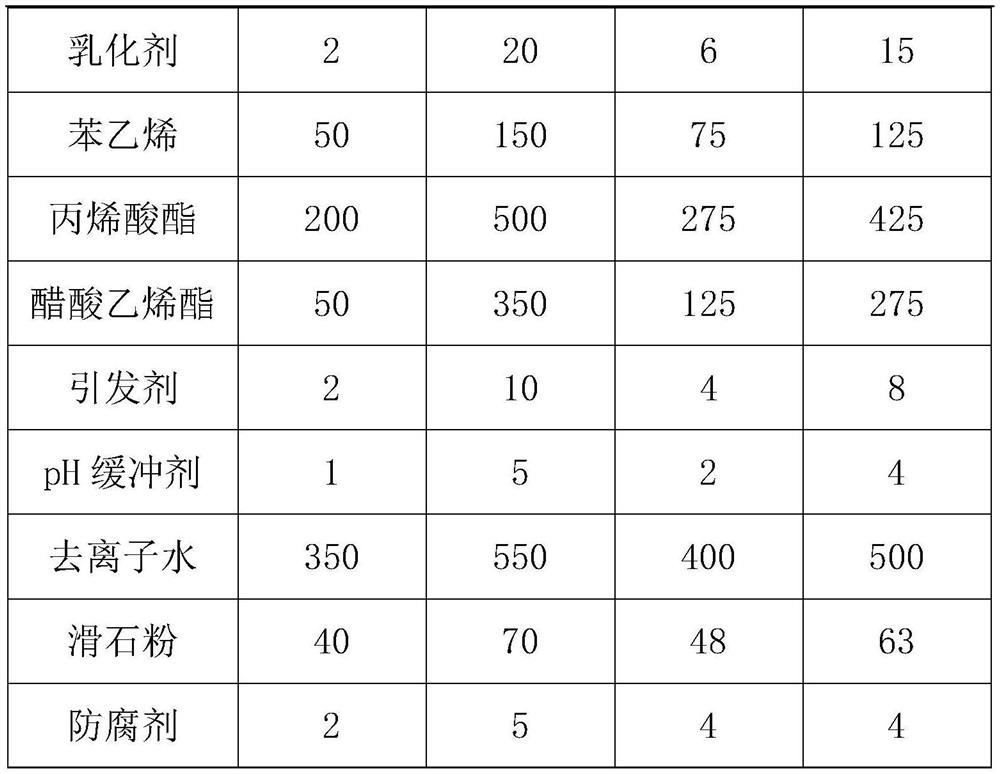

[0062] refer to figure 1 , this embodiment discloses a preparation method of quick-drying glue for office use, comprising the following steps: the following substances are all in parts by weight;

[0063] S1: Preparation of emulsion. Add 200 parts of deionized water into the first reaction vessel by weight, the first reaction vessel is an emulsification tank, and start stirring. Then add 11 parts of emulsifier, 100 parts of styrene, 350 parts of acrylate and 200 parts of vinyl acetate at the same time, and keep stirring until the material in the first reaction vessel is milky white to prepare an emulsion for later use. Among them, the acrylate is selected from methyl acrylate; the emulsifier is selected from polyoxyethylene ether.

[0064] S2: Aggregation stage. Add 250 parts of deionized water into the second reaction vessel, the second reaction vessel is a reaction kettle, and before adding the deionized water, first raise the temperature of the deionized water to 75° C.,...

Embodiment 2

[0067] This embodiment discloses a preparation method of quick-drying glue for office use, which includes the following steps: the following substances are all in parts by weight;

[0068] S1: Preparation of emulsion. Add 200 parts of deionized water into the first reaction vessel by weight, the first reaction vessel is an emulsification tank, and start stirring. Then add 11 parts of emulsifier, 100 parts of styrene, 350 parts of acrylate and 200 parts of vinyl acetate at the same time, and keep stirring until the material in the first reaction vessel is milky white to prepare an emulsion for later use. Among them, the acrylate is selected from ethyl acrylate; the emulsifier is selected from sodium lauryl sulfate.

[0069] S2: Aggregation stage. Add 250 parts of deionized water into the second reaction vessel, the second reaction vessel is a reaction kettle, and before adding the deionized water, first raise the temperature of the deionized water to 75° C., and start stirrin...

Embodiment 3

[0072] This embodiment discloses a preparation method of quick-drying glue for office use, which includes the following steps: the following substances are all in parts by weight;

[0073] S1: Preparation of emulsion. Add 200 parts of deionized water into the first reaction vessel by weight, the first reaction vessel is an emulsification tank, and start stirring. Then add 11 parts of emulsifier, 100 parts of styrene, 350 parts of acrylate and 200 parts of vinyl acetate at the same time, and keep stirring until the material in the first reaction vessel is milky white to prepare an emulsion for later use. Wherein the acrylate is selected from butyl acrylate; the emulsifier is selected from sodium dodecylbenzenesulfonate.

[0074] S2: Aggregation stage. Add 250 parts of deionized water into the second reaction vessel, the second reaction vessel is a reaction kettle, and before adding the deionized water, first raise the temperature of the deionized water to 75° C., and start st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com