Method for preparing macromolecular material/graphene nanometer composite material by adopting continuous mixing in-situ reduction as well as application thereof

A technology of nanocomposite materials and polymer materials, which is applied in the field of polymer materials/graphene nanocomposite materials and its preparation, and can solve the problems of continuous preparation of nanocomposite materials, difficulties in achieving good stripping and dispersion of RGO, and the degree of RGO reduction limited problems, to achieve the effects of easy promotion, avoiding unfriendly environment, and improving the effect of chemical reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

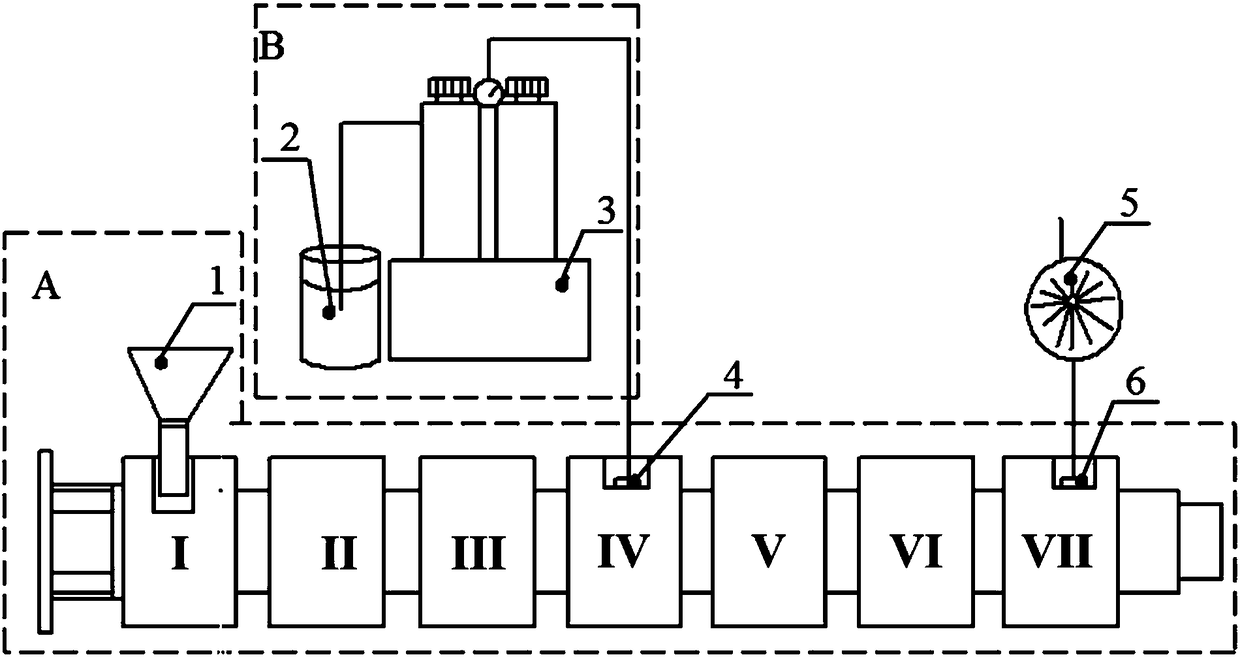

[0037] The water-assisted melting mixing extrusion equipment adopted in the present invention comprises an extruder, a set of water injection device, and a water ring vacuum pump. Along the flow direction of the material, the barrel of the extruder is provided with a feeding port, a water injection port and an exhaust port. The feed port is used for feeding the premixed polymer material and graphene oxide powder mixture, the water injection port is used for the injection of the chemical reducing agent aqueous solution, and the exhaust port is used for the discharge of water vapor. The water injection port is equipped with a nozzle, and the nozzle is connected with a water injection device, and the water injection device includes a liquid storage cylinder and a metering pump. The exhaust port is connected to a water ring vacuum pump.

[0038] Add vitamin C (VC) into deionized water and stir at room temperature until VC is completely dissolved to obtain a VC aqueous solution (0...

Embodiment 2

[0040] This embodiment adopts the water-assisted melt kneading extrusion equipment of embodiment 1, but the feeding method is different from embodiment 1. The feed port is used for the feeding of polymer materials, and the water injection port is used for the injection of graphene oxide dispersion liquid containing chemical reducing agent.

[0041] GO powder was ultrasonically exfoliated and dispersed in water to obtain a GO dispersion (10 mg / ml); then VC was added to the GO dispersion with a mass 10 times that of GO and stirred until VC was completely dissolved to obtain a VC-containing GO dispersion. Place in the reservoir. In the dispersion liquid, water was used as a dispersant to promote the stripping and dispersion of GO and increase the contact area between VC and GO. Put the TPU pellets into the extruder for plasticization and melting; when the internal pressure of the melt in the water injection section of the extruder reaches above 2MPa, the GO dispersion containing...

Embodiment 3

[0043] This embodiment adopts the water-assisted melt kneading extrusion equipment of embodiment 1.

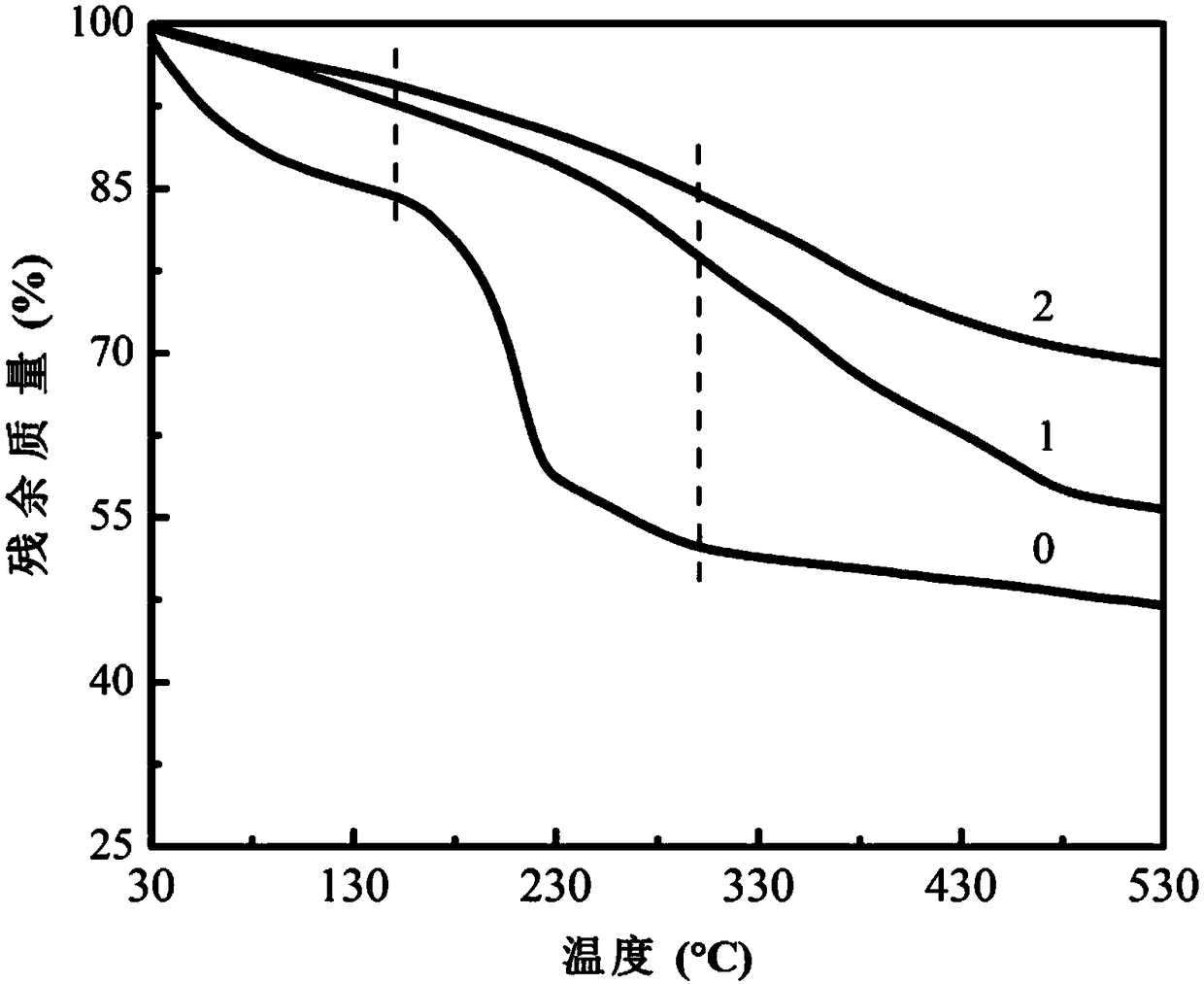

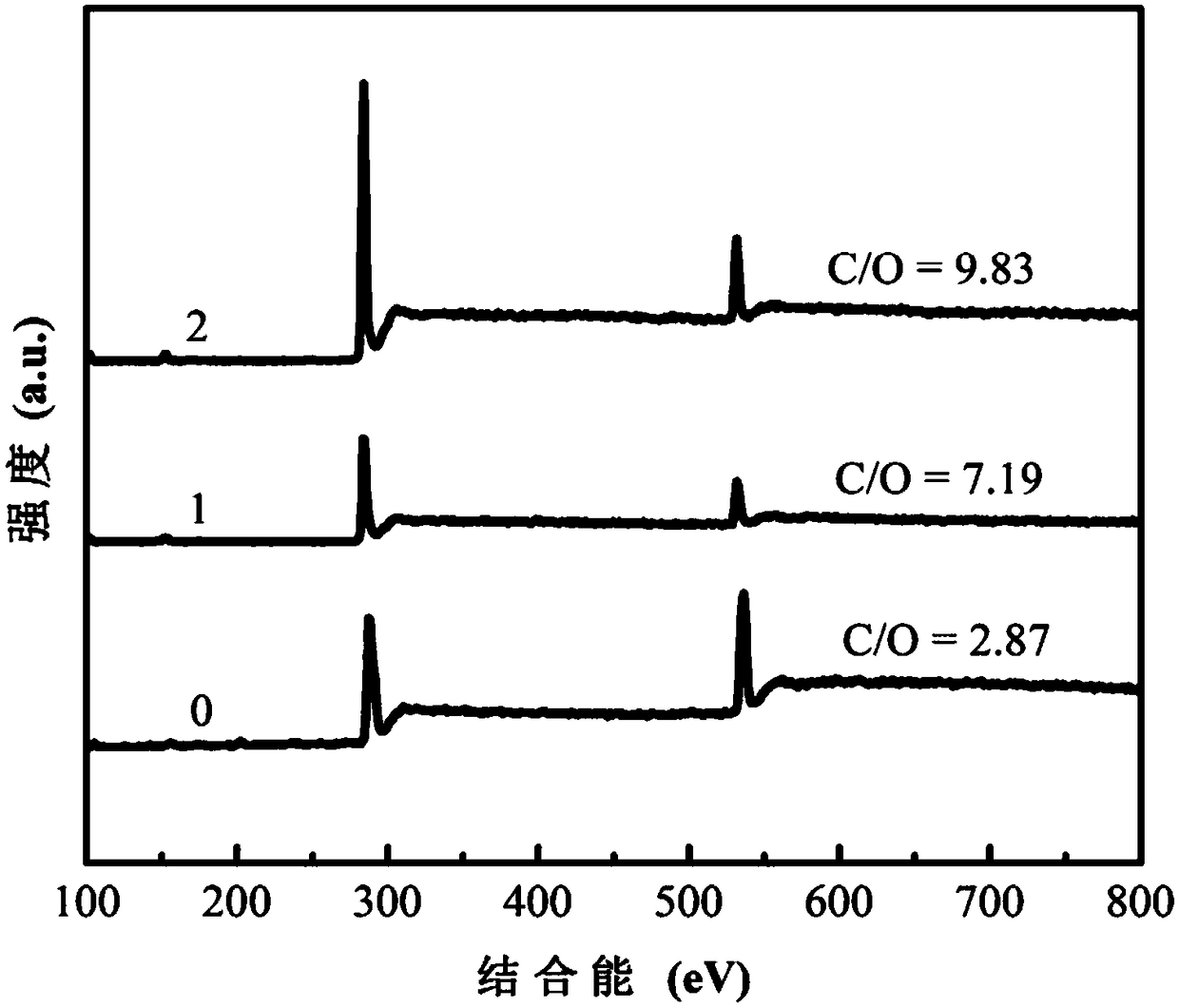

[0044] Add VC to deionized water and stir at room temperature until VC is completely dissolved to obtain VC aqueous solution (0.20g / ml), which is placed in a storage tank; premix TPU pellets and GO powder at a mass ratio of 100:0.95 and then add Melt and knead in the extruder; when the melt pressure in the water injection section of the extruder reaches above 2MPa, inject the VC aqueous solution into the melt at a certain flow rate (1.45L / h) by means of a metering pump. During the mixing process of the injected VC aqueous solution and the TPU melt containing GO, the VC aqueous solution enters between adjacent graphene oxide sheets under the mixing action of the extruder screw, which promotes the formation of graphene oxide in the melt. Stripping and dispersion, in-situ chemical reduction and in-situ thermal reduction; water is vaporized in the exhaust section to form water vap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com