Thin film field effect transistor type gas sensor and preparation method thereof

A thin-film field effect and gas sensor technology, which is applied in the direction of transistor, semiconductor/solid-state device manufacturing, semiconductor devices, etc., can solve the problems of unsuitable air atmosphere, limit low-power gas sensing, etc., and achieve improved sensitivity, room temperature gas sensitivity Enhanced effects and wide application scenarios

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

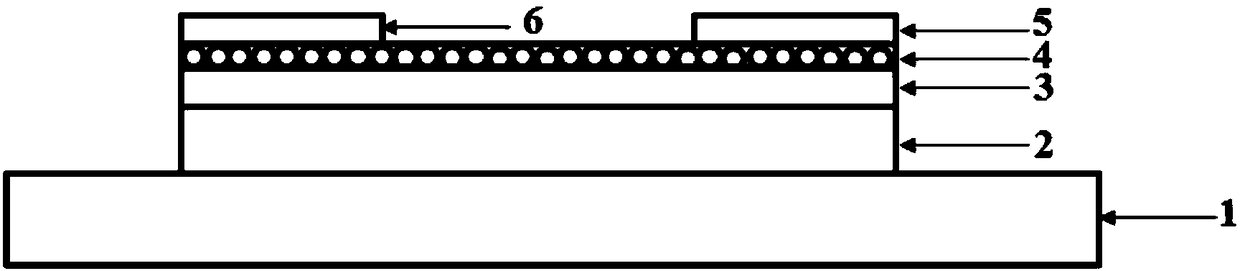

[0052] Embodiment 1: prepare bottom gate top contact type PbS quantum dot thin film field effect transistor type gas sensor (such as figure 1 shown), specifically may include the following steps:

[0053] (1) Preparation of PbS colloidal quantum dot solution. PbO can be used as the lead source, and hexamethyldisilathane (TMS) can be used as the sulfur source, which can be produced by colloid chemical reaction.

[0054] Specifically, 0.9 g of PbO can be dissolved in 5 ml of oleic acid (OA) and 20 ml of octadecene (ODE) under a nitrogen atmosphere and heated to 90° C. to prepare a precursor of lead oleate as a lead source. After evacuating for 8 hours, the temperature of the precursor was raised to 120°C. Dissolve 280 μl TMS into 10 ml ODE as a sulfur source. Rapidly inject the sulfur source into the lead source at 120°C, and after the color of the reaction system turns black (about 15s), put the solution into cold water to rapidly drop the temperature to room temperature. A...

Embodiment 2

[0063] Example 2: Preparation of bottom-gate top-contact SnO 2 Quantum dot thin film field effect transistor type gas sensor (such as figure 1 shown), specifically may include the following steps:

[0064] (1) Preparation of SnO 2 Colloidal quantum dot solution. SnCl can be used 4 ·5H 2 O is used as a tin source, and oleic acid and oleylamine long-chain organic ligands are used as encapsulating agents, which are produced by colloidal chemical reaction.

[0065] Specifically, 0.6g SnCl can be 4 ·5H 2 O. 20ml of oleic acid and 2.5ml of oleylamine were heated to 100°C and vacuum-dried until the reaction was clear, cooled to 60°C, 10ml of ethanol was taken out and mixed evenly, then added to a stainless steel autoclave, and placed in an oven at 180°C for 3 hours. After the reaction is completed, take it out, and when it is cooled to room temperature, take out the solution in the autoclave, mix it with ethanol and centrifuge the precipitate, then disperse the precipitated pr...

Embodiment 3

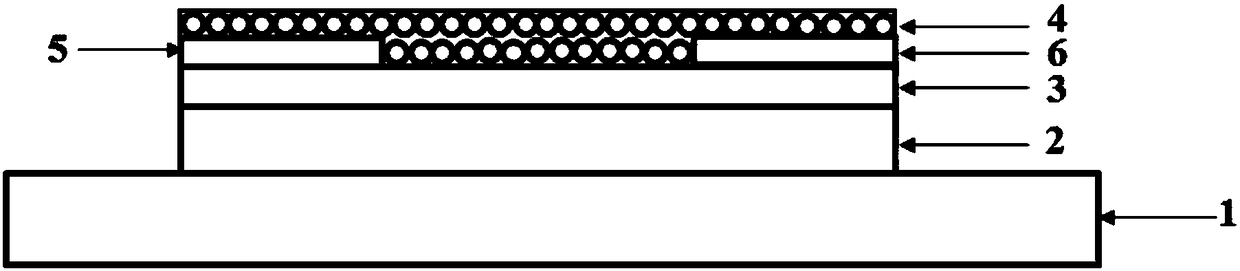

[0067] Embodiment 3: prepare bottom gate bottom contact type PbS quantum dot thin film field effect transistor type gas sensor (such as figure 2 shown), specifically include the following steps:

[0068] (1) Preparation of PbS colloidal quantum dot solution. PbO can be used as the lead source, and hexamethyldisilathane (TMS) can be used as the sulfur source, which can be produced by colloid chemical reaction.

[0069] Specifically, 0.9 g of PbO can be dissolved in 5 ml of oleic acid (OA) and 20 ml of octadecene (ODE) under a nitrogen atmosphere and heated to 90° C. to prepare a precursor of lead oleate as a lead source. After evacuating for 8 hours, the temperature of the precursor was raised to 120°C. Dissolve 280 μl TMS into 10 ml ODE as a sulfur source. Rapidly inject the sulfur source into the lead source at 120°C, and after the color of the reaction system turns black (about 15s), put the solution into cold water to rapidly drop the temperature to room temperature. A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com