A Structure Design for Improving the Sensitivity of Mos2 Thin Film Field Effect Transistor Gas Sensor

A gas sensor and thin film field effect technology, applied in the direction of material resistance, can solve the problems that limit the development of low-power gas sensing, and achieve the effects of enhanced room temperature gas-sensing effect, high surface activity, and excellent conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

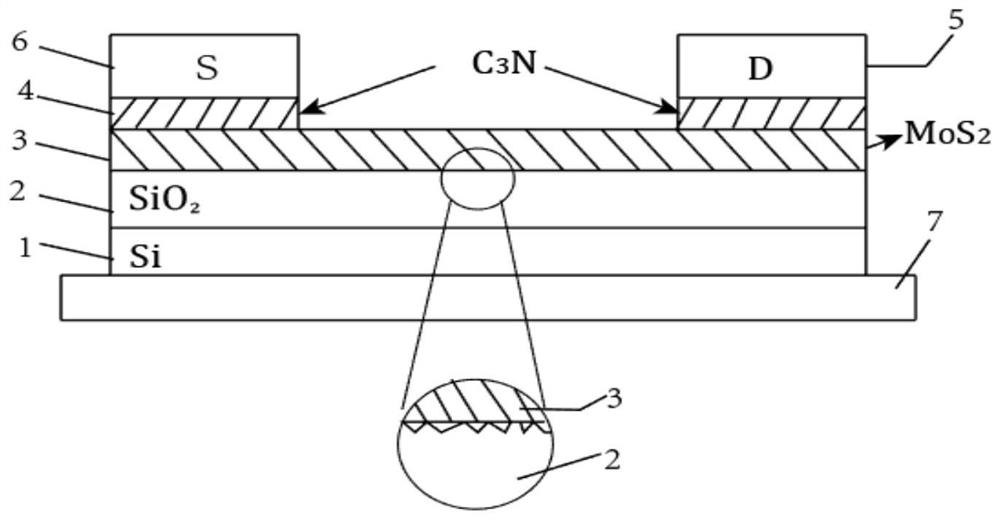

[0031] The MoS-based 2 Thin film field effect transistor gas sensors (such as figure 1 shown), including: substrate (1), gate insulating layer (2), channel active layer (3), 2DC 3 N electrode deposition carrier (4), source electrode (6) and drain electrode (5), and grid (7) made of indium tin oxide (commonly known as ITO) film transparent conductive glass.

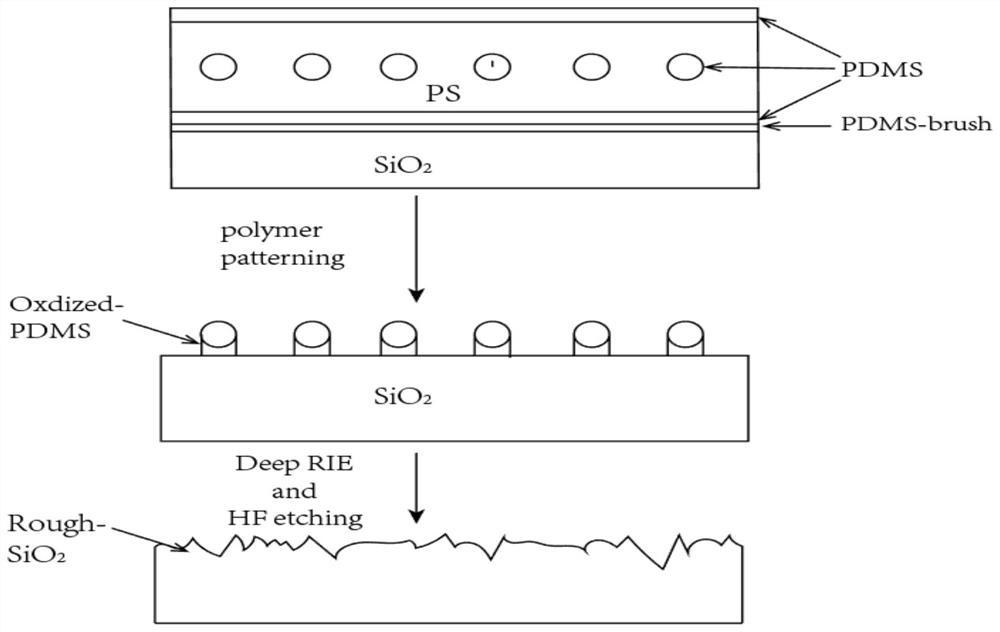

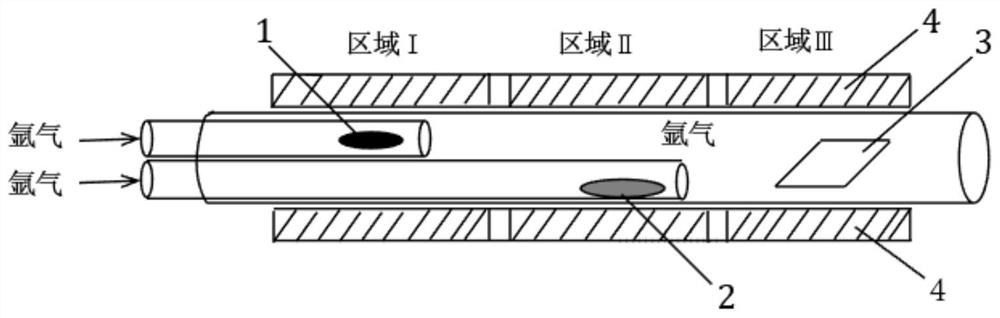

[0032] The preparation method can adopt the following steps: use chemical vapor deposition (CVD) to deposit a single layer of MoS 2 The thin film is deposited on a silicon-based substrate to form a channel active layer, where a gate insulating layer is pre-deposited on the silicon-based substrate, and undergoes ion etching and HF wet etching; a single-layer two-dimensional material (2D) C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com