Dustproof pavement grooving machine

A slotting machine and pavement technology, applied in roads, roads, road repair and other directions, can solve the problems of dust and garbage easily scattered into the air and environmental pollution, and achieve the effect of reducing air pollution, optimizing the working environment and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

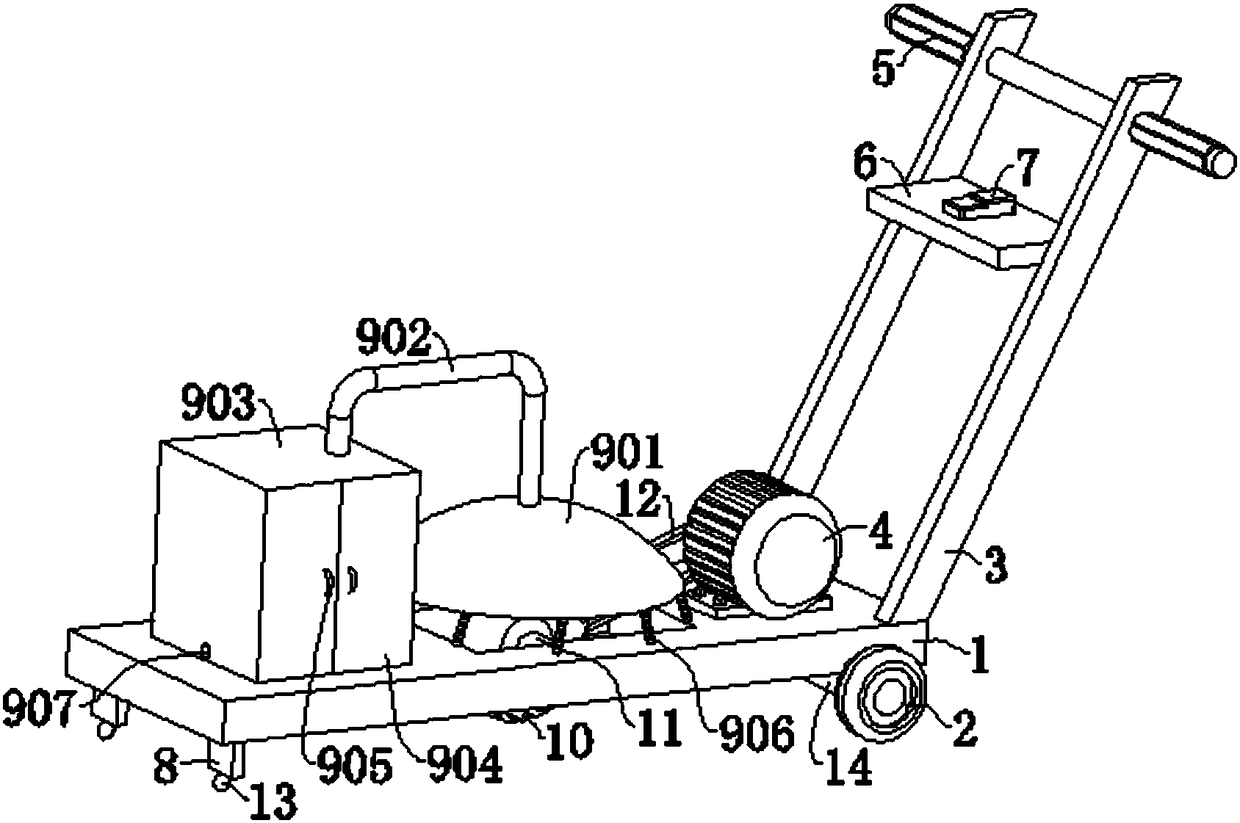

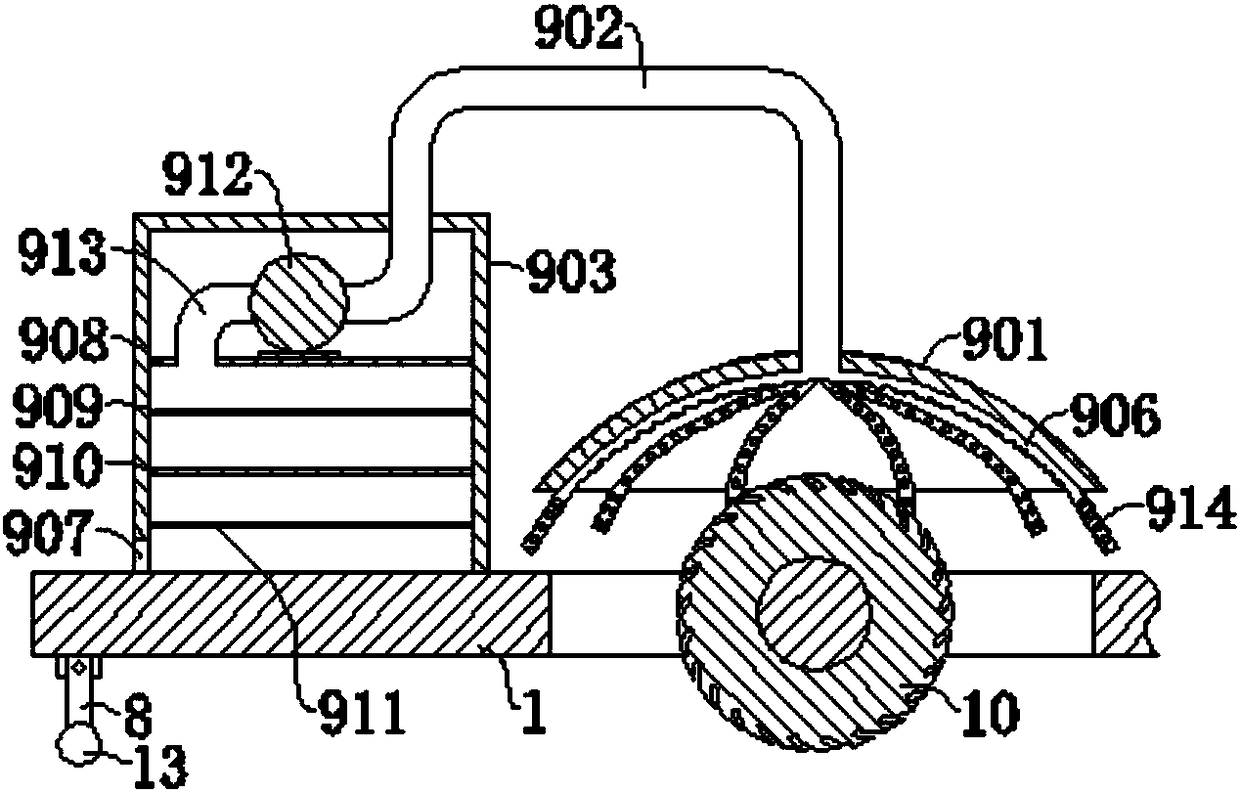

[0033] Embodiment: a kind of dust-proof pavement slotting machine, as figure 1 , 2 Shown, comprise base 1, wheel 2, push rod 3, dustproof device, blade 10 and driving motor 4. Wheel 2 is provided with two, and two wheels 2 are respectively positioned at the rear portion both sides of base 1, is provided with connecting shaft 14 between two wheels 2, and two wheels 2 are respectively fixed on connecting shaft 14 two ends, and connecting shaft 14 and The bottom of the base 1 is turned and set. The bottom of the base 1 is provided with two supporting legs 8, and the two supporting legs 8 are respectively located on both sides of the front of the base 1, the top of the supporting legs 8 is hinged to the bottom of the base 1, and the bottom of the supporting legs 8 is provided with balls 13 flush with the ground. The ball 13 and the supporting leg 8 are rotated and set. The blade 10 is located below the base 1, the center of the blade 10 is fixed with a rotating shaft 11, the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com